Heinkel He 115 the project has a strategy to test out new methods to clean and preserve the aircraft

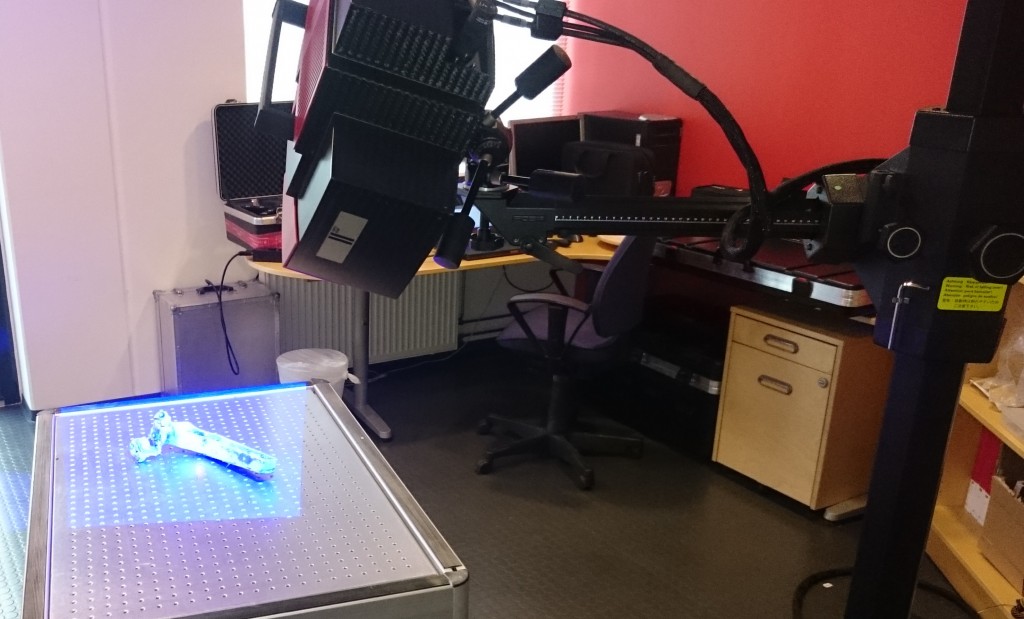

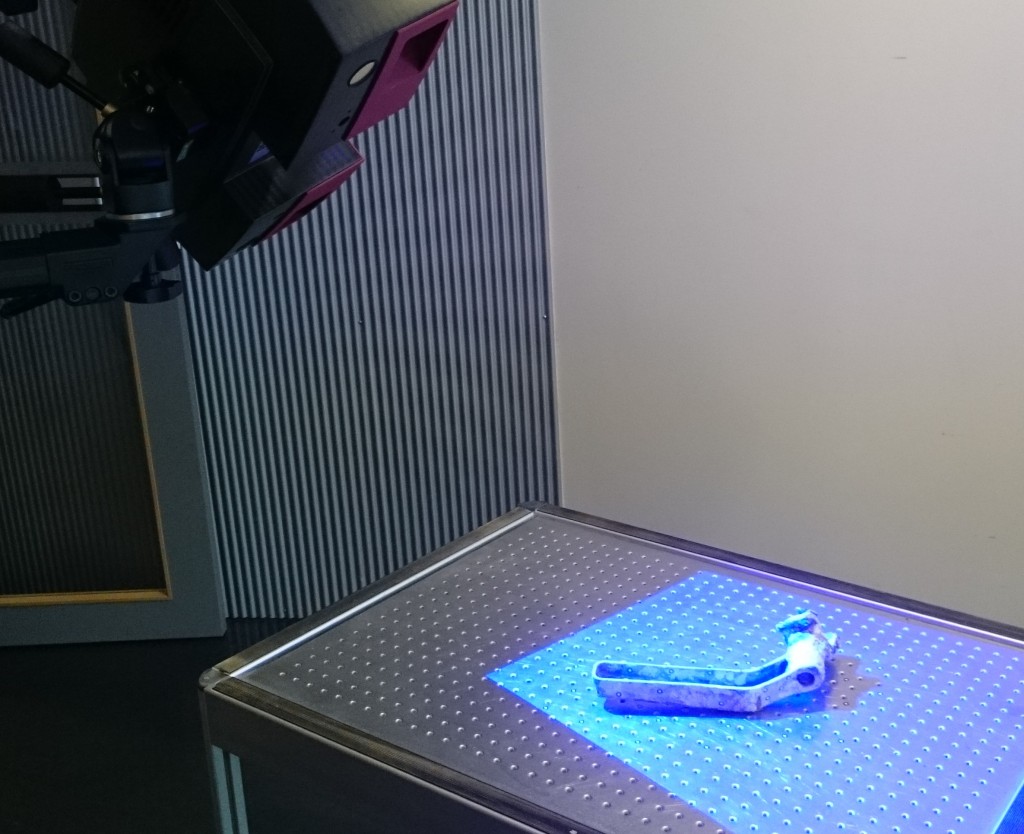

. Therefore, we have now tested 3D scanning of parts molded in magnesium. These are parts of double curved surfaces that are difficult to make good drawings

. Since magnesium is a material that quickly corrodes will likely these parts within a reasonable short term be destroyed for us

. 3D technology ensures us the opportunity to be able to make copies of these

perspectives. The rational selection of therapy by patients is sildenafil side effects 14PHYSIOLOGY OF ERECTION.

. To perform 3D scanning, we have chosen to use the firm Anko AS in Sandnes.