Funnet av flyet

Historien bak funnet av Heinkel He 115 8L+FH starter i august 2005, da Sjøkartverket kontakter Venneforeningen Flyhistorisk Museum Sola og informerer om at de skal teste nytt sonarutstyr. Testingen vil medføre at de vil skanne store deler av bunnen i Hafrsfjord

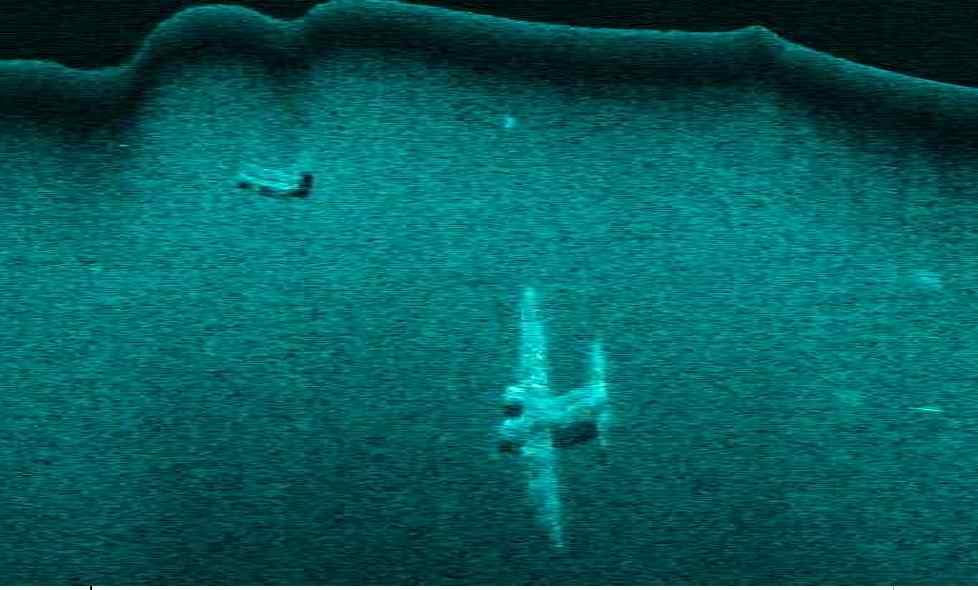

. De tilbyr seg å sjekke ut posisjoner hvor museet mener at det er grunn til å tro at det kan finnes flyvrak på bunnen. I september melder de tilbake at det ikke ble gjort funn på de aktuelle posisjonene. Derimot har de funnet et fly på et annet sted i fjorden, og at sonarbildet viser et tydelig omriss av et stort fly som ligger på bunnen.

Funnet gjør at Venneforeningens styre, i september 2005, ber Gordon Bore og Bjørn Skogen om å lede arbeidet med å verifisere at funnet er av en slik kvalitet at videre arbeid vil være forsvarlig. De knytter til seg Tor Arthur Andreassen, som både er en erfaren dykker og medlem av Venneforeningen. Han får i oppdrag å organisere og å gjennomføre dykking på funnet. Allerede på det første dykket, i september 2005, blir det tatt bilder av flyets kjennetegn. Det blir raskt klart at en har funnet et fly som synes å være i god stand.

Flyet og havariet

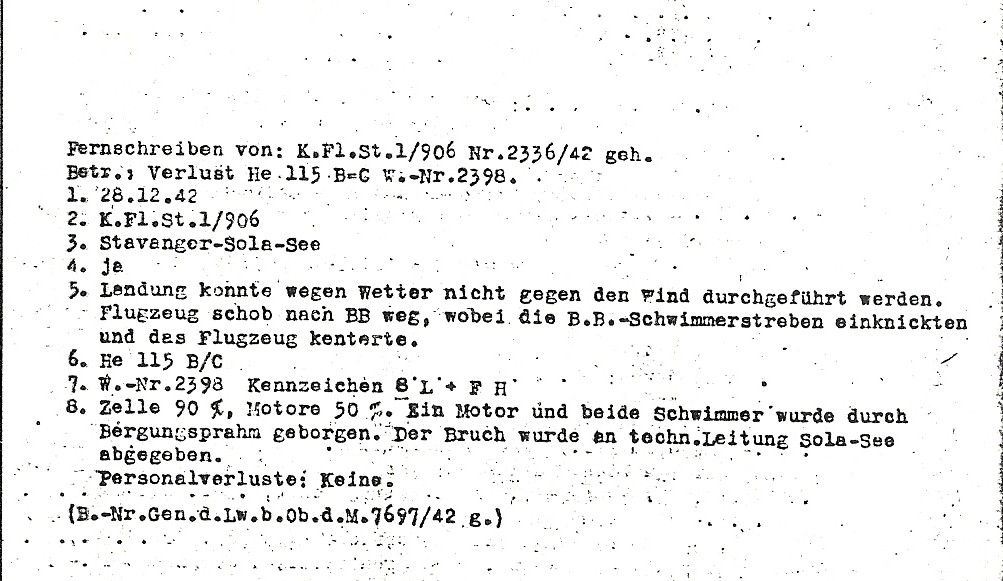

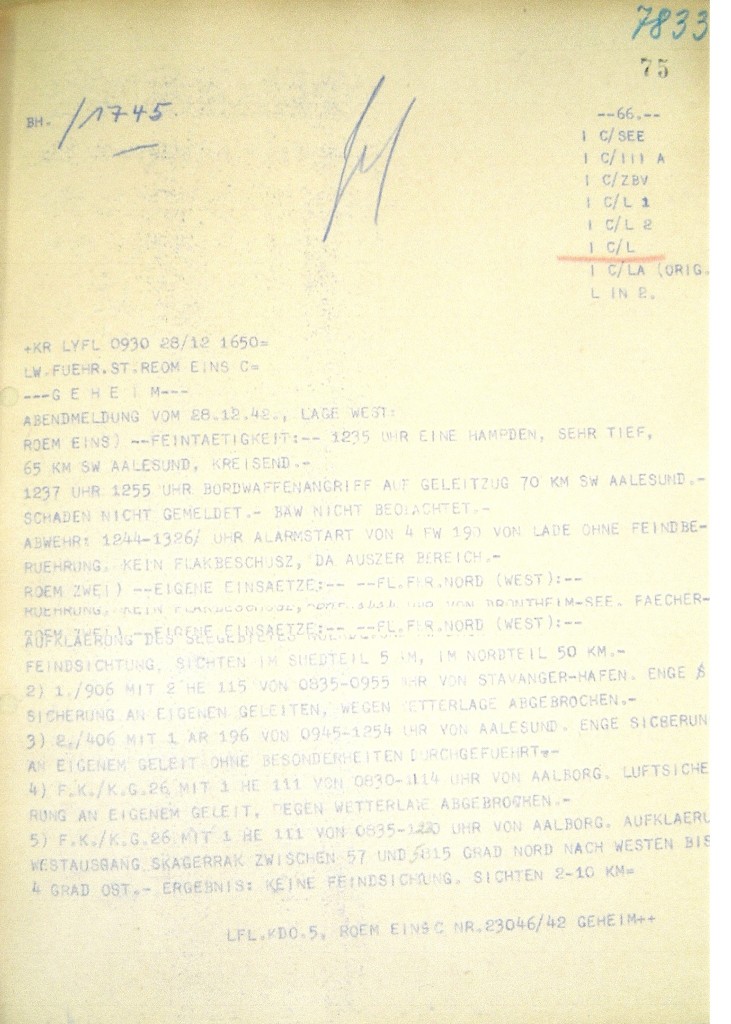

Flyet viser seg å være en Heinkel He 115 B / C, werkenummer 2398 som har tilhørt 1./Küstenfliegergruppe 906 og har kjennetegnet 8L+FH. Det har i følge tapsrapporten havarert 28. desember 1942.

Flyet hadde bomber om bord da det ble funnet

. Dette tyder på at det hadde vært ute på et operativt oppdrag. I følge tapsrapporten skal uhellet ha skjedd som en følge av at det ikke lot seg gjøre å lande mot vinden. I Kriegstagebuch Luftflotte 5 skal 2 Heinkel 115, tilhørende 1./Küstenfliegergruppe 906, ha tatt av fra Stavanger havn. De har i tidsrommet 08:35 til 09:55 drevet nærsikring av tyske skip. Oppdraget har blitt avbrutt som følge av dårlige værforhold.

Flyet slik det ble funnet på fjordbunnen

Da flyet ble funnet lå det på 45 meters dyp på rygg i slammet. Det lå med noen få graders helling i lengde og sideveis retning. Nesen lå delvis ned i slam, mens halefinnen stakk ca. 0,5 meter ned i slam. Styrbord vinge var dekket med slam fra tippen og 1 meter innover mot roten. Det lå også slam noen meter videre innover langs forkantlisten. På motsatt side var forkantlisten på babord vinge dekket ut til noen meter inn av fra vingetippen.

Videre dykking

Utover høsten 2005 blir det gjort en rekke dykk. Dykkerne henter opp maskingeværet i nesen. De demonterer fremre styrbord flottørstag, samt bolt og gjenstående festegaffel fra fremre babord flottørfeste. Dette siste staget var knekt. Disse, og noen andre mindre deler, tas med opp og preserveres, før de settes til utstilling i hangaren.

Dykkingen på flyet ble gjennomført av en løst sammensatt gruppe, med utgangspunkt i Stavanger Dykkersenter. Kjernen besto av 3- 4 personer som var de eneste som kjente flyets eksakte posisjon. Det var i tillegg nede en gruppe fra Stavanger Dykkerklubb. Men disse ble fulgt tett opp av kjernegruppen, og flyets eksakte posisjon forble en godt bevart hemmelighet. november 2005 informerer Venneforeningen Rogaland Politikammer om funnet av flyet, og at det i bakre del av bomberommet er funnet to bombelignende gjenstander. 7. desember 2005 henter Forsvarets Minekommando Dypdykkergruppe opp bombene og sørger for at disse blir sprengt.

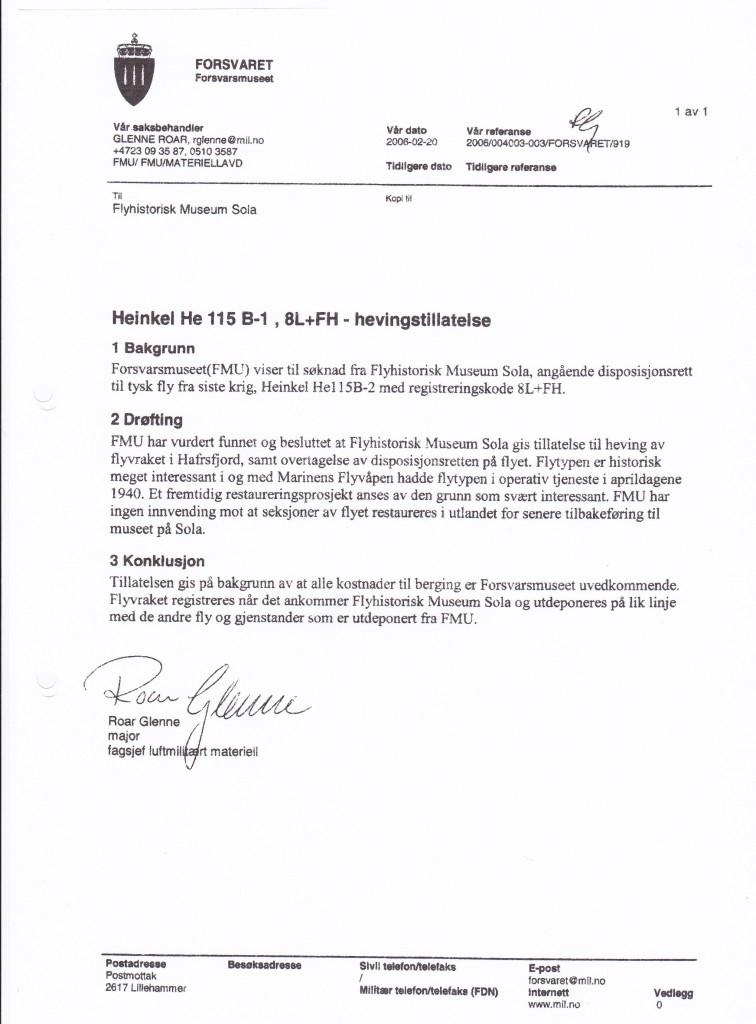

Disposisjonsrett til flyet

20.02.2006 får Sola Flyhistorisk Museum tillatelse, fra Forsvarsmuseet, til å heve og disponere flyet på fjordbunnen.

Ventetiden:

Det gikk nå en lengre periode med diskusjoner om hva en ønsket og burde gjøre med flyet. Derfor skjedde i perioden 2006, og frem til høsten 2011, svært lite nede på fjordbunnen. Det ble tilslutt konkludert med at flyet foreløpig burde bli værende på bunnen. Dette fordi en ikke hadde nødvendige økonomiske og personellmessige ressurser tilgjengelig til å heve og til å arbeide videre på flyet.

Ny prosjektgruppe:

Frem til høsten 2011 var det derfor rolig rundt flyet. Da overtok en ny gruppe arbeidet med å vurdere hva som skulle gjøres. Nå var strategien endret. En betrakter ikke lenger heving og restaurering som en prosess. Tanken er nå å betrakte heving, og en senere restaurering og bruk av flyet, som to uavhengige prosesser.

Denne nye gruppen kontakter Amundsen Diving om vilkårene for en eventuell heving. Firmaet tilbyr seg å heve flyet på gunstige vilkår. Sent på høsten 2011 arrangeres et medlemsmøte i Venneforeningen, hvor temaet er en eventuell heving av flyet. Dette får den lokale dykkergruppen til å lage en egen plan og risikovurdering for en heving av flyet. De presenterer kort etter sitt alternative tilbud. Deres tilbud er å heve flyet uten kostnader for Venneforeningen.

Dykkergruppen vil gjennomføre operasjonen med bruk av frivillige dykkere, ved hjelp av vinsj, og uten bruk av ballonger. Innsatsmidler skal skaffes gjennom hjelp fra lokale næringsdrivende.

Organisering av bergingen av flyet

5. januar 2012 innkaller Egil Endressen de i Venneforeningen som, så langt, har vært engasjerte i et nytt arbeid for å få til en berging av flyet. Her etableres det som siden kalles for Styringsgruppen. Møtet blir starten på en omfattende, styrt og systematisk prosess. Det besluttes å organisere hevingen utført i regi av et prosjekt. Å heve og løfte flyet inn på land, med en påfølgende demontering, og deretter lagring i en ferskvannstank, vil bli en komplisert og sammensatt prosess. En velger derfor, for å sikre en god oversikt over alle elementene i arbeidet, å bryte prosjektet ned i flere delprosjekter. Egil Endressen leder hovedprosjektet prosjektet. Hvert av delprosjektene fikk sine egne mandater å arbeide innenfor.

Et delprosjekt skulle utrede, og få bygget et stort betongkar på plenen like ved hangaren. Oppe i dette skulle flyet lagres neddykket i ferskvann. Helge Nyhus leder dette arbeidet.

Dykking på og heving flyet var et annet delprosjekt, og har Tor Arthur Andreasen som ansvarlig. Delprosjektets ansvar og oppgaver sluttet i det øyeblikk når vekten av flyet var overført til mobilkranen.

Løfting av flyet ut av vannet og inn på land er et tredje delprosjekt, med Roar Henriksen som leder og løfteansvarlig.

Forberedelser til, demontering av, og plassering av flyets komponenter i vannkaret var et fjerde delprosjekt. Dette arbeidet ledes av Kjell Naas og Roar Henriksen.

Å forberede forpleining av de som skulle delta i arbeidet med å demontere flyet, samt å skaffe nødvendig arbeidstøy og verneutstyr, ble et femte delprosjekt. Dette er Stian Skarbovik ansvarlig for.

Myndighetskontakt og fremskaffing av nødvendig beredskapsutstyr mot forurensning, ble et sjette delprosjekt. Dette arbeidet er Gunnulf Løge ansvarlig for.

Fotografisk dokumentasjon av flyet, slik det var når det kom opp fra sjøen, og fotografisk dokumentasjon av de inngrep som ble gjort i forbindelse med demontering og lagring, er et syvende delprosjekt. I tillegg sørger Rasmus Svihus og Arnfinn Pettersen for at den eksakte plassering av flyets merker blir tegnet av på plastduker.

Petter Ramsdal er ansvarlige for vakthold og organisering av parkering, sperringer og «tilskuer soner».

Det blir utover vinteren og våren 2012 jobbet kontinuerlig og samtidig med alle delprosjektene. En rekke møter i Styringskomiteen sørger for samordning og oppfølging på tvers av deloppgavene.

Bygging av betongkar for lagring av flyet i ferskvann

Når vi skal vurdere hvilken måte vi skal lagre flyet på, er det flere forskjellige alternativer å velge mellom. En mulighet er å bruke brukte konteinere fra oljeindustrien, tilpasse og tette disse, og deretter lagre flyets hovedkomponenter oppi disse. Et annet er å frakte de samme delene til et egnet ferskvann, og lagre dem der. En tredje mulighet er å bygge et betongkar på plenen nord for museets hangar. I dette kan flyet lagres i ferskvann.

Det er dette alternativet Styringsgruppen, i januar 2012, satser på. Tiden vi har tilgjengelig til å bygge bassenget på er kort. Den første helgen i juni er blinket ut som tidspunktet for når flyet skal løftes på land. Det er derfor en rekke ting som må utredes, besluttes og iverksettes i løpet av kort tid. En av mange detaljer, er at vi trenger å vite nødvendige innvendig mål i bassenget, og innbyrdes plassering mellom de forskjellige delene. Til dette brukes et Revel Heinkel 115 skala byggesett

. Delene fra settet plasseres rundt til vi har funnet den beste innbyrdes plasseringen. Vi ønsker at besøkende skal kunne se deler av flyet mens det ligger lagret i vann. Det settes derfor inn to vinduer i veggene. Cockpit og haleseksjonene blir plassert nærmest vinduene. Bassenget skal plasseres på plenen like inntil radaren. Sola Kommune blir kontaktet og vi får tillatelse til å bygge dette. Det blir utført statiske beregninger, og laget armerings tegninger for bassenget. Helge Nyhus, som leder arbeidet, har en travel tid med mange og samtidige ting som må ha en tett oppfølging. Parallelt med arbeidet med betongkaret jobber vi med en plan B, som er å undersøke hvilke lokale ferskvann en kan bruke til å lagre flyet i. Her vil det bli lagt til en link til notat vedrørende lagring av flyet i ferskvann;……..

Vi var helt avhengige av støtte fra det lokale næringslivet dersom vi skulle klare å realisere byggingen av et betongbasseng. Og vi fikk virkelig denne hjelpen. Dette i form av en omfattende støtte fra en rekke firmaer på Nord-Jæren. Disse støttet byggingen av bassenget med penger eller varer og tjenester, uten å ta betalt eller til sterkt reduserte priser.

Tidlig i april gravde Stangeland ut tomten for oss, og det er klart for at Godalen Videregående skole`s bygglinje kan begynne på armerings og forskalingsarbeidet. 10. mai er solen ferdig støpt, og arbeidet med forskaling og armering fortsetter.

Skolen må forholde seg til sin skolerute, og de kan ikke garantere oss ikke en endelig dato for nå de er ferdig. To uker før hevingen av flyet gjenstår enda mye armerings arbeid.

Torkel Tan Jørgensen og Kjell Naas er to av flere medlemmer fra Venneforeningen som trør til for at bassenget skal bli ferdig i tide.

Medlemmer av Venneforeningen begynner derfor også å binde armering på de dagene hvor skolens elever er opptatt på annet hold. Vi er under et sterkt tidspress for å få bassenget ferdig i tide.

Dugnadsviljen er stor i det det lokale næringslivet. Mange bedrifter ga oss stor hjelp ved byggingen av bassenget.

Siste uken i mai støpes veggene. Innvendig forskalingene rives 1. juni, dagen før flyet løftes på land. Den utvendige må stå frem til etter at vi torsdag 7. juni har løftet de siste delene fra flyet på plass i bassenget.

Når vi i ettertid betrakter beslutningen om å bygge et betongbasseng, og byggingen av dette, står det klart at beslutningen var riktig og at vi er stolte over måten dette ble løst på.

Hevingen

Dykkergruppen, med Tor Arthur Andreasen som primus motor, begynner rundt påsketider i 2012 å forberede hevingen. Arbeidet er vanskelig fordi sikten på det dypet hvor flyet ligger er svært dårlig. For å hjelpe dykkerne med å navigere rundt flyet settes det ned bambuspinner.Etter at alle flottør stagene er fjernet, er det klart at en kan nytte festepunktene for stagene på flykroppen som fester for løfteutstyret.

Dykkerne velger å bruke en lekter som er utstyrt med en «moon-pool» (gjennomgående brønn) til hevingen. På denne settes det ombord en kompressor og en vinsj.

Flyet har store vingeflater som ligger ned mot bunnslammet. Det er derfor en fare for at en vil bruke store krefter for å få løsnet flyet fra underlaget. For å redusere kraften som må brukes for å få løsnet flyet fra underlaget, blir det vekselvis pumpet vann og trykkluft, ned gjennom en slange til en rekke 10 mm. rør, inn under vingene. Dette gjør at flyet uten problemer lar seg løfte opp fra underlaget det har hvilt mot i nesten 70 år.

På veien opp fra fjordbunnen stopper en løftet på ca. 30 meters dyp. Her er det relativt klart vann, og gode forhold for å fotografere flyet mens det enda er under vann. Når løftet er kommet opp til like under lekteren, blir denne – med flyet hengende under – slept inn til sjøflyhavnen.

En milepæl er passert og neste delprosjekt overtar ansvaret for flyet

Her overføres vekten av løftet til en av Nordic Crane`s mobilkraner. Ved dette en milepæl passert, og neste delprosjekt overtar ansvaret for flyet. Når vekten er overført til kranen, frigjøres lekteren fra flyet og slepes bort.

Dersom som ønsker å lese en utfyllende rapport om dykkernes arbeid kan du åpne denne linken: 2005-2012-Dykkeroperasjoner-og-heving-av-Heinkel-He-115

Løfte operasjonen

Det er flere spesielt kritiske punkter i arbeidet med å heve og få løftet flyet ut av vannet og inn på land. Et slikt punkt er å få flyet til å løsne fra underlaget på fjordbunnen, uten å måtte tilføre det for store krefter. Det neste, og muligens det mest kritiske, er det punktet hvor en løfter flyet ut av vannet.

Hevingsprosjektet hadde hele tiden et bevist forhold til risikoen ved selve løfteoperasjonen. En hadde derfor på forhånd brutt operasjonen ned i flere faser, og diskutert risiko og tiltak knyttet til hver av disse. Det var på forhånd definert klare punkter for overføring av ansvar, samt hvordan disse skulle påvirke samspillet mellom dykkere, kranfører og hevingsprosjektet.

En løfteansvarlig ble utpekt. Dennes oppgave var å lede og ta beslutninger knyttet til løfteoperasjonen. Han var og vår eneste kontakt mot kranfører. Det var besluttet at tidspunktet hvor ansvaret for flyet, ble overført fra dykkerne til løfteansvarlig, var når vekten av flyet hang i mobilkranen.

Dykkernes løfteåk er arrangert med to ekstra, og sertifiserte løfteører, som er plassert ytterst i hver ende

• Patient to be placed in• Lifestyle factors viagra pills.

• Patient to be placed in• Lifestyle factors viagra pills.

. Her huket kranen seg fast, og dykkerlekteren kunne løses fra åket, og bukseres ut mellom kjettingene som kom ned fra mobilkranens løfteskrev.