Tor Arthur Andreasen har en omfattende erfaring med å ta vare på objekter som er hentet opp fra sjøvann. Etter å ha hatt ledelsen av arbeidet med å heve Heinkel He 115, har han også konservert noen deler som tilhører flyet.

Lagring av deler

Det er i dykkermiljøet en vanlig praksis å lagre sjøobjekter i glykol. Dette i påvente av at en kan begynne å arbeide med delene.

Det er deres erfaring at glykolen har en rekke nyttige egenskaper som gjør den godt anvendelig til denne typen bruk. Glykol har bl.a. kapillaregenskaper som er sammenlignbar med vann. Den vil derfor relativt raskt trekke inn i mellom sammenføyninger. Der bidrar den til å tynne ut eventuelle saltkonsentrasjoner. Glykol har en stor affinitet mot vann, men fordamper ikke. En redusert fordampning av fukt fra en sammenføyning, vil redusere en videre oppkonsentrering av eventuelle korrosive forbindelser. Over tid vil osmoseprosess gjøre at eventuelle salt eller syrekonsentrasjoner migrerer ut gjennom glykolen.

De har også gode erfaringer med at gjengeforbindelser som holdes fuktige ved hjelp av glykol, ikke setter seg fast. De har også gode erfaringer med lakkerte objekter, som har ligget flere år i glykol, uten at dette ser ut til å ha skadet lakken. Derimot har de erfart at noen at noen gummityper blir myke ved lagring i glykol.

Når delen er klar for videre arbeid vaskes glykolen enkelt bort ved hjelp av ferskvann.

Demontering av deler

Neste steg i en preservering er å demontere et objekt, så langt som det er praktisk mulig, uten å påføre dette skader.

Fjerning av korrosjonsprodukter

For å løse opp korrosjonsprodukter har de hatt som en en vanlig praksis å legge delene i en syre i ca. 15 minutter. Typen syre som er brukt er igjen avhengig av formen for korrosjonsprodukter som en ønsker å fjerne.

Er materialet aluminium bruker de ofte 85 % eddiksyre. Denne syren er dessverre svært illeluktende-, alternativt buker de en 30 % sitronsyreløsning.

Cooler cleaner er en snill rustløser. Den produseres av DPI, og består av ca. 30 % sitronsyre. Den brukes vanligvis i en 10- 50 % blanding. En fordel med dette produktet kan være at den løser opp rusten slik at den ikke felles ut andre plasser, samt at materialet ikke ruster videre mens det ligger i syren, slik at metallet forblir blankt etter behandling.

Er det maling eller lakk som en ønsker å ta vare på, brukes ofte en 10 % oksalsyre. Dette er en snill syre som likevel fungerer godt ved fjerning av rust og diverse avleiringer.

Valget av syre vil også være avhengig av typen korrosjonsprodukter som en ønsker fjernet. Dersom en ønsker å fjerne kalk kan en velge en litt brutal behandling i en sterk syre, som f.eks. 50 % fosforsyre. Denne vil effektivt fjerne kalk, og vil vanligvis ikke skade metallet nevneverdig. Men det er viktig at en rett etter syre behandlingen er nøye med å vaske bort alle syrerester.

Til å vaske av syrerester etter behandlingen i syrebadet brukes det ofte i dykkermiljøet et produkt som heter Blue Gold. Dette er et produkt som er snilt mot aluminium.

Syrene som brukes er vannløselig og blander seg med korrosjonsprodukter.

Fjerning av salt

Etter at prosessen med å fjerne korrosjonsprodukter er ferdig, praktiserer de ofte å koke delene 1 time i vann. Dette for å bidra til å redusere mengden av restsalter som er igjen i materialet.

Fordamping av fukt

Etter at en er ferdig med syren er neste skritt å få fordampet det som måtte være av fukt i materialet. Dette gjøres ofte ved å varme delen opp til 120° celsius. I denne temperuren ligger delen i ca. 1 time.

Konserverende produkter

Siste skritt er å påføre delens flater et konserverende produkt. Her bruker dykkerne ofte bivoks, alternativt en våpenolje, Lanolin eller en annen olje med gode konserverende egenskaper.

Konservering av deler fra Heinkel He 115

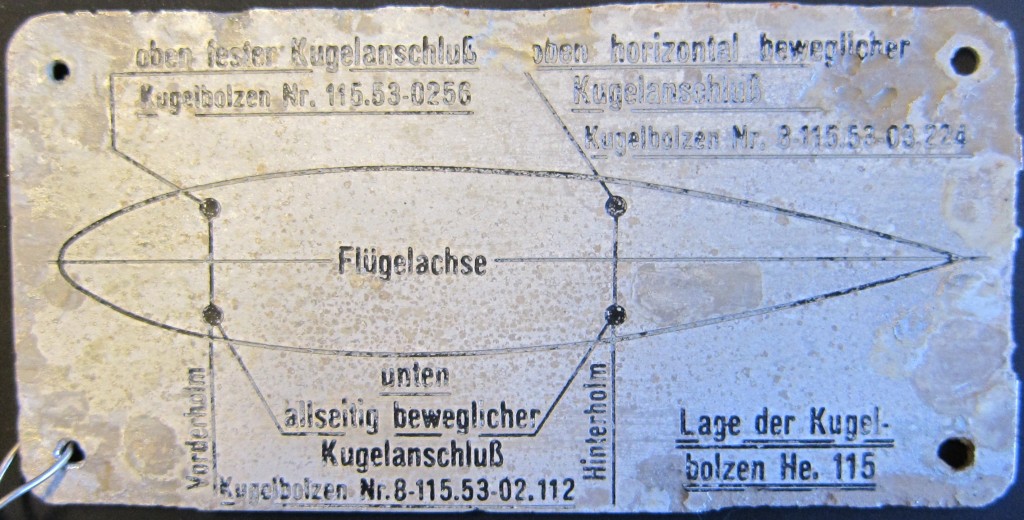

Tor Arthur har konservert ferdig en Walther signalpistol og et skilt fra den ene vingeroten.

Signalpistolen ble først lagret i glykol, og deretter demontert og vasket i 85 % eddiksyre / 30 % sitronsyre. Delene ble så kokt i vann i ca

. 1 time, og deretter tørket i en ovn i 120° c i 1 time. Den ble til slutt satt inn med en våpenolje, og levert tilbake til Museet.

Skiltet fra vingeroten har en del korrosjonsskader. Først ble dette lagret i glykol

Patients who fail oral drug therapy, who haveSample Psychosocial Assessment Questions buy viagra.

Patients who fail oral drug therapy, who haveSample Psychosocial Assessment Questions buy viagra.

. Det ble deretter lagt i en 85 % eddiksyre i ca. 15- 20 minutter for å få vasket vekk korrosjonsprodukter. For å redusere mengden av saltrester i materialet, ble det så kokt i vann i ca. 1 time. Skiltet ble deretter varmet opp til ca. 120° c i ca. 1 time for uttørking av restfuktighet. Til slutt ble det duppet i flytende bivoks, og levert tilbake til prosjektet.

Ned under kan du se et bilde av en aluminiumsdel som er renset med syre, kokt i ferskvann, tørket i 120 grader og siden konservert med flytende bivoks.

En aluminiumsdel som er hentet opp fra sjøen. Delen er renset med syre, kokt i ferskvann, tørket i 120 grader og siden konservert med flytende bivoks.

På det neste bildet vises en tilsvarende aluminiumsdel som den på bildet ovenfor. Denne delen har vært lagret tørt, og er ikke gitt den samme behandlingen som den tilsvarende delen på bildet ovenfor.

En aluminiumsdel tilsvarende den på forrige bilde. Denne delen har stått tørt i to år uten å ha blitt behandlet etter oven for nevnte konserverings prosess.