Vi har siden i sommer arbeidet videre med å klargjøre Kanzel for å igjen å kunne montere denne sammen med cockpit seksjonen.

Det har underveis i dette arbeidet vært nødvendig å åpne opp noen få plate / ribbe sammenføyninger. Dette for å rengjøre disse for pågående korrosjon. For å sikre rørstrukturene mot videre innvendig korrosjon er det her blitt sprøytet inn Owatrol.

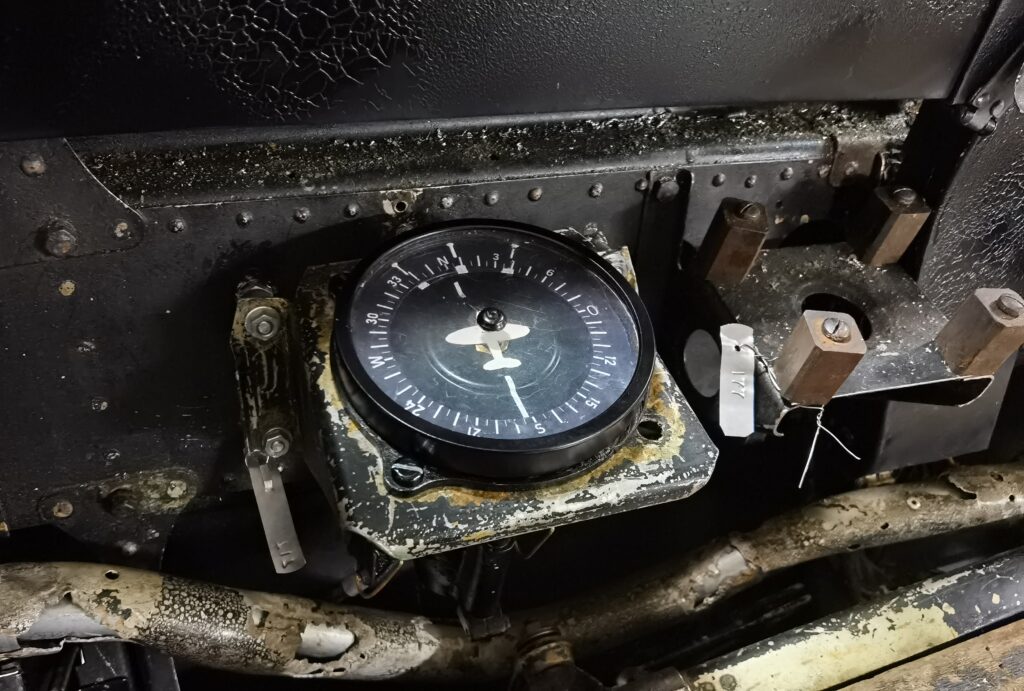

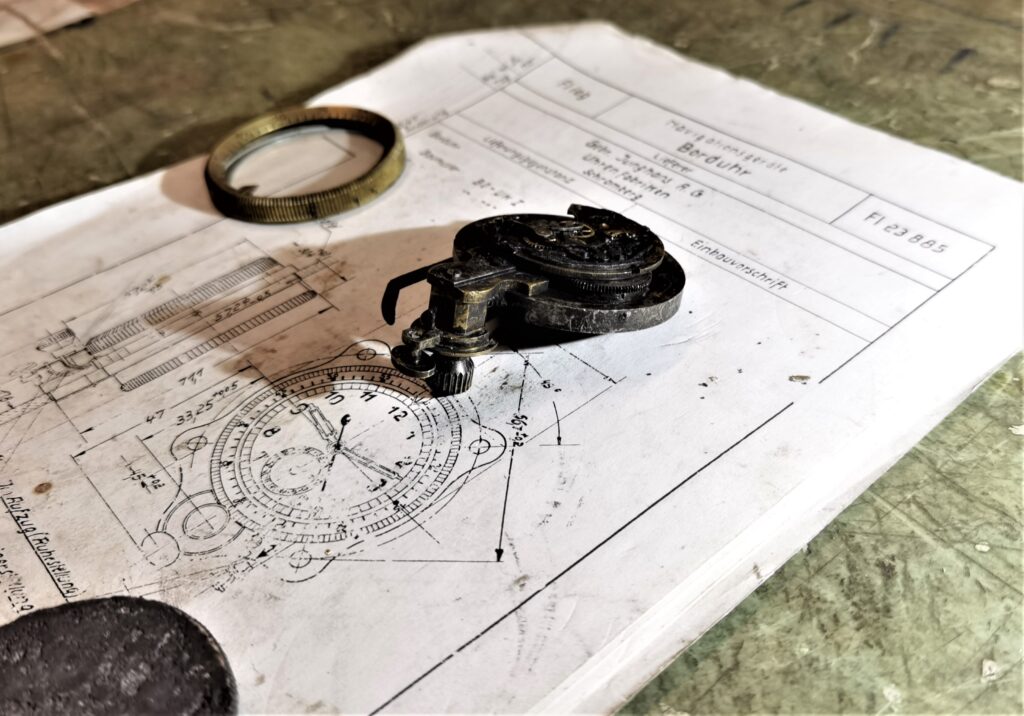

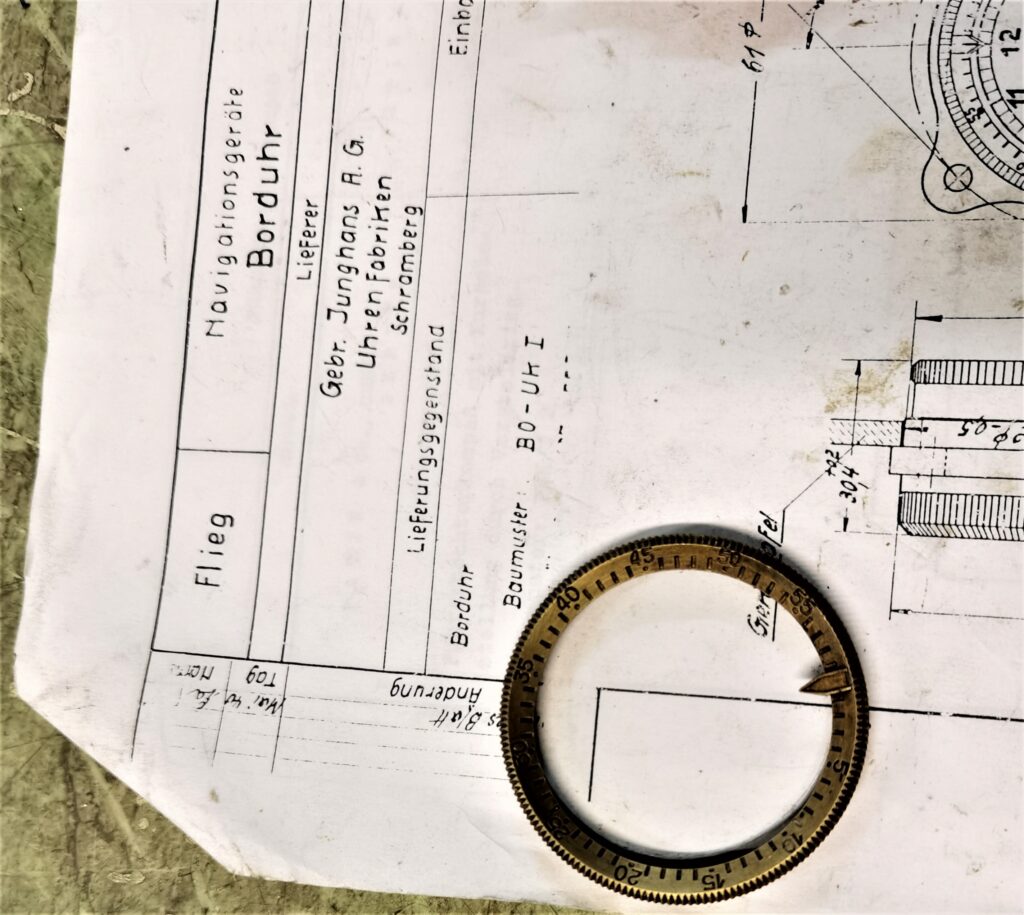

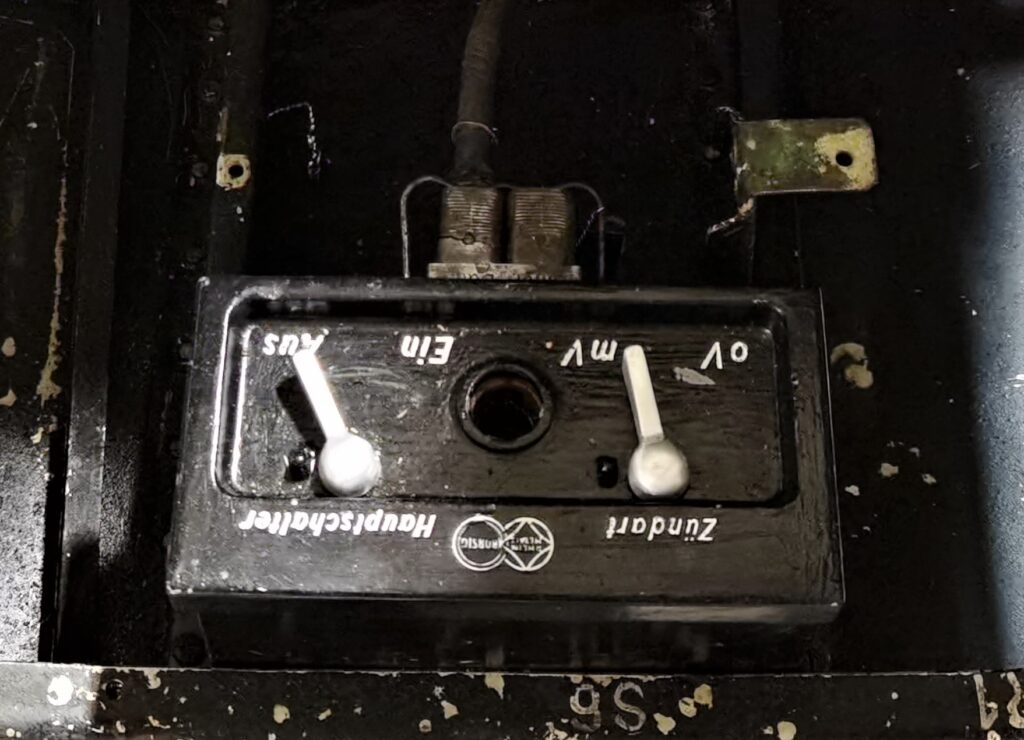

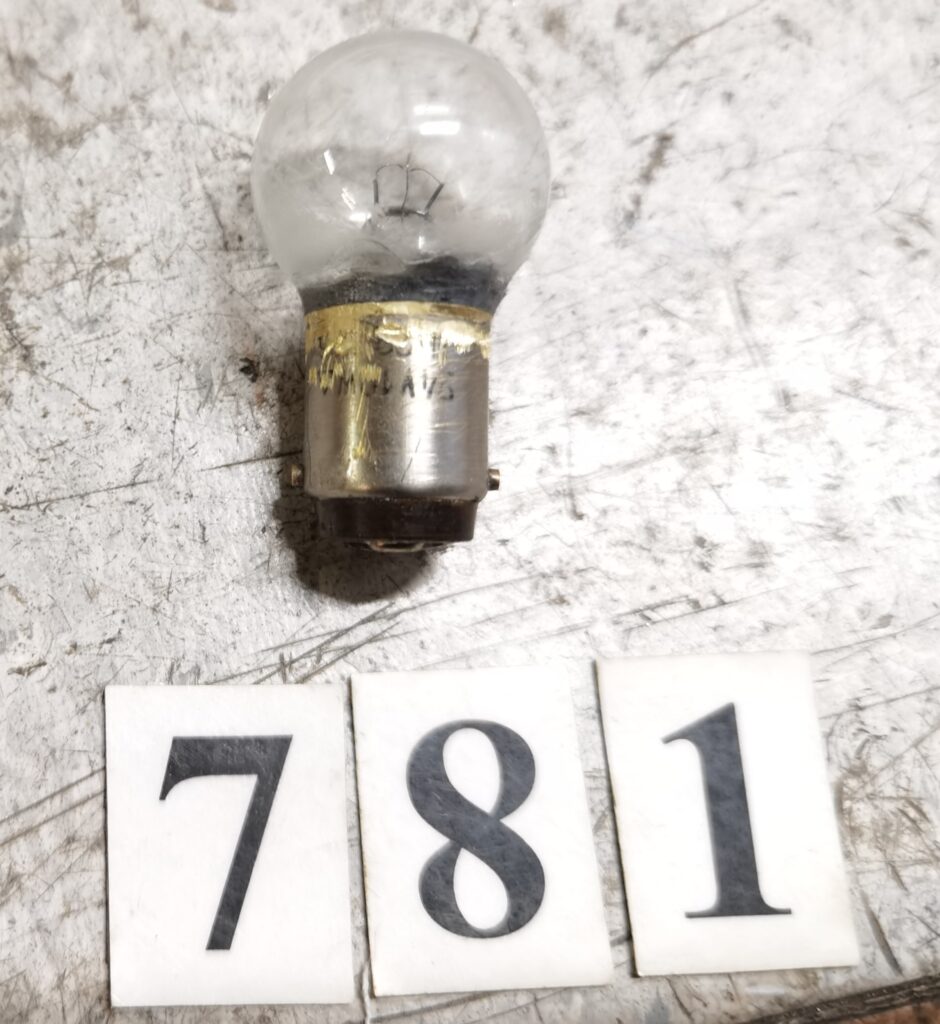

Det er også arbeidet mye med å konservere og å gjenoppbygge originale instrumenter og andre komponenter som brytere og elektriske komponenter. Mange av disse komponentene er nå tilbake montert i Kanzel.

Kabelgate for ledningsnettet var i løpet av tiden på fjordbunnen korrodert helt bort og det har derfor blitt laget en ny tilsvarende kabelgate.

Det er også blitt laget nye tre kassetter for oppbevaring av lyspatroner. Videre er det blitt gjort mye arbeid med å rengjøre og gjenoppbygge MG 15 brillemagasiner.

Vi er snart der hvor videre arbeid med Kanzel vil være avhengig at denne monteres sammen med cockpit seksjonen. Dette fordi det er flere store systemer som er gjennomgående fra Kanzel og bakover gjennom cockpit.

Parallelt med arbeidet med Kanzel har det blitt jobbet med å klargjøre senterseksjon for NDT undersøkelser av bærebjelkene. For å skaffe tilgang til å kunne måle bakre bærebjelker, er bakkant av senterseksjon blitt løst i fra hovedstrukturen.

IKM Inspection AS ga oss 11. oktober vederlagsfritt en ultralyd undersøkelse av bjelkene. Utrolig nok viste disse målingene ubetydelige variasjoner i material tykkelsene. Dette gir oss et godt håp for å kunne slippe å gjøre veldig store inngrep i senterseksjonen. Vi arbeider nå med å forberede for i løpet av 2022 å løfte senterseksjonen ut av betonghallen og inn på verkstedet.