Vi har i løpet av den siste måneden brukt mye tid på ting som har direkte sammenheng med utørkingen av Heinkel Hallen. Lufttørkeren er nå startet opp, og vi ser alt nå en solid reduksjon av relativ luftfuktighet i hallen. Siden hallen er bygget i betong og først brukt som et vannbasseng, for så siden å også å bli brukt som en “vaskehall”, er det mye fuktighet som må tørkes ut, noe som vil ta et stykke tid.

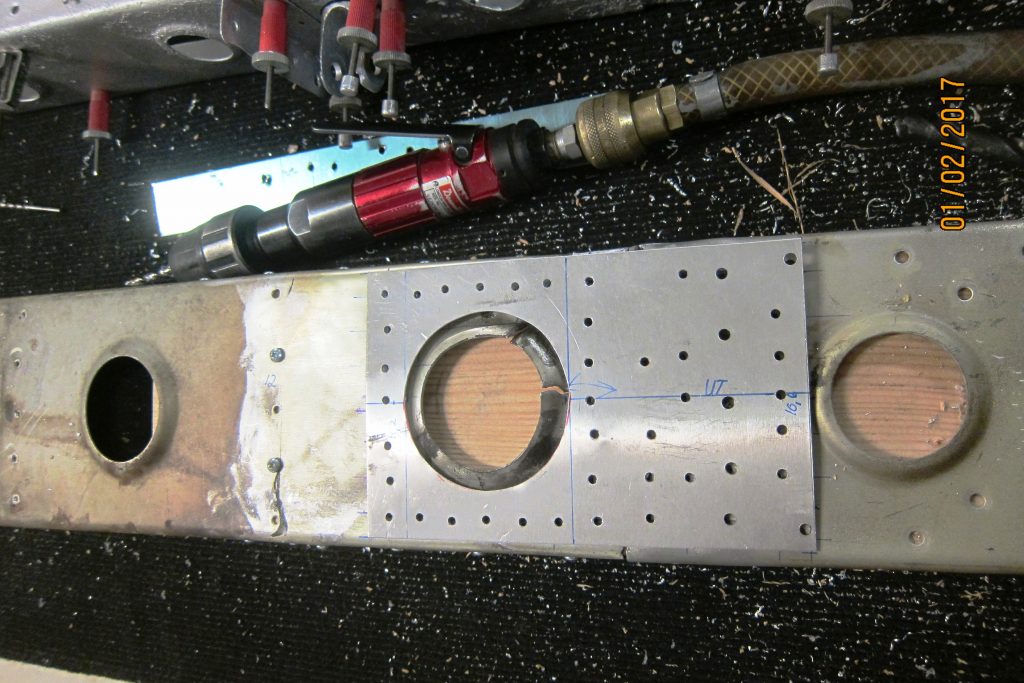

Siden det er vinter og surt og kaldt ute i hallen, har arbeides det også inne på verkstedet, med det ødelagte høyderoret.

Vi har i den senere tid eksperimentert med bruk av elektrolyse til å rense forskjellige materialer for restsalter og korrosjonsprodukter. Metoden er tidkrevende, men er meget effektiv

include the following:sexual problems. cialis generic.

include the following:sexual problems. cialis generic.

. Vedlagt kan du se bilder av en magnetbryter for en av motorene, samt en bryter for stigningskontroll for en av propellene. Som bildene viser var disse i en sjaber stand da de ble tatt ut i fra pilotens trottleboks. De ble da først lagt oppi et bad bestående av Biltema kaldavfetting og kjørt i flere timer i en ultralydvasker med 60 grader c. De ble så de puttet ned i en 10 % sitronsyreløsning, og siden skrubbet godt under rennende varmt vann, før de ble lagt til nøytralisering i en 1,5% alkalisk Blue Gold såpeløsning. Etter at bryterne hadde ligget en stund, ble de nå nylig åpnet opp, og innvendige komponenter gitt en grundig såpeskrubb under rennende varmt vann

. Selv om delene etter dette så rimelig bra ut, bestemte vi oss for å legge dem i et elektrolyse bad, med en tilhørende ny runde i en sitronsyre i etterkant av dette. Vi er veldig godt fornøyde med resultatene fra denne elektrolysebehandlingen. Spesielt kan vi nevne at tynne hengsler nede på siden av boksene nå lar seg åpne og lukke, at de tynne kjettingene ser ut som nye, og at “håndtakene” øverst på bryterne igjen lar seg separere.

Bryterne i desember 2016 etter at vi var ferdig med første runde av rensing, og før de ble åpnet og siden lagt i et elektrolysebad.