Året 2020

Året 2020 ble et godt år for Heinkel 115 prosjektet hvor gjennom mange positive ting har skjedd.

Vi har

gjennom flere år hatt restriksjoner for hvilken type arbeid som vi kunne gjøre

på flyet. I løpet av året som har gikk har Forsvarets Museer langt på vei opphevet

disse restriksjonene.

Den

tidligere Heinkel 115 styringsgruppen er nedlagt. Som en erstatning for denne

er det etablert en støttegruppe med medlemmer fra Venneforeningen, samt to

konservatorer som er engasjert av Jærmuseet. Denne løsningen gir oss som

arbeider med flyet en enkel tilgang til en meget allsidig erfaring og

kompetanse.

Det også i

løpet av året som har gått blitt en omforent forståelse for at det kan være

nødvendig å gjøre noen inngrep på senterseksjonen. Dette gjelder i hovedsak bærebjelker,

med tilhørende innfestninger for vinger og flottører. Dette har medført at det nå

blir arbeidet for å finne løsninger for hvordan et slikt arbeid kan bli

gjennomført. Vårt mål er fortsatt å gjøre små inngrep og konservere så mulig så

mye av denne seksjonen.

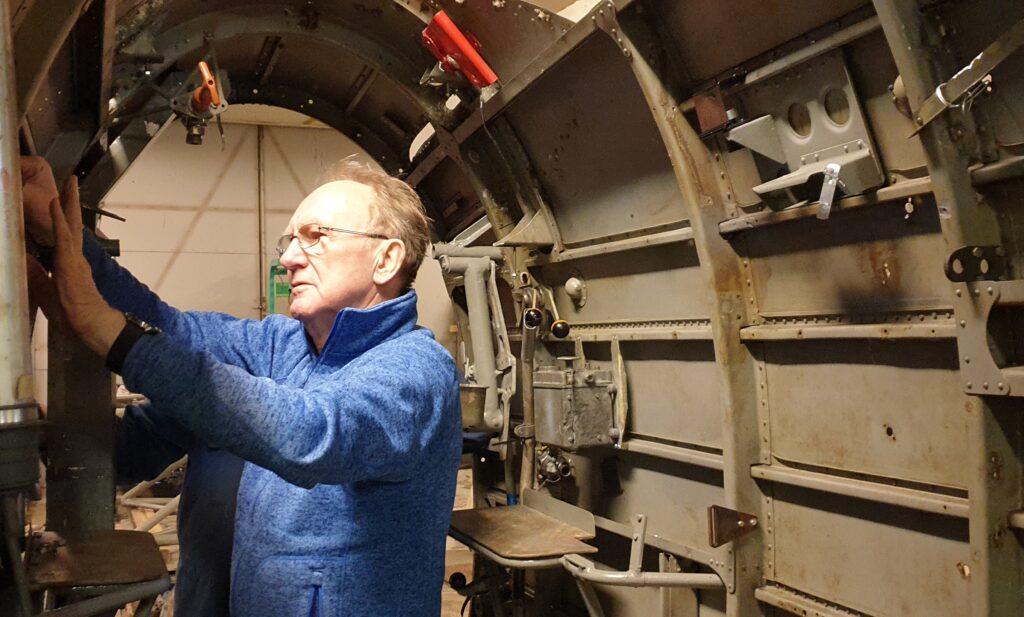

Det har

gjennom hele året blitt arbeidet med en rekke forskjellige delprosjekter. I de

tilfeller hvor utstyr helt ødelagt integrerer vi det som måtte være igjen av

det originale utstyret i det nye som bygges.

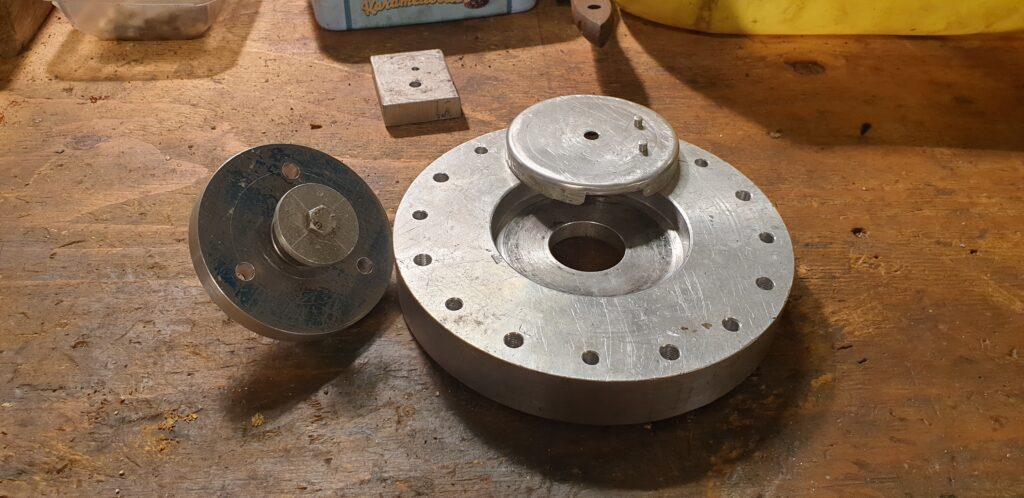

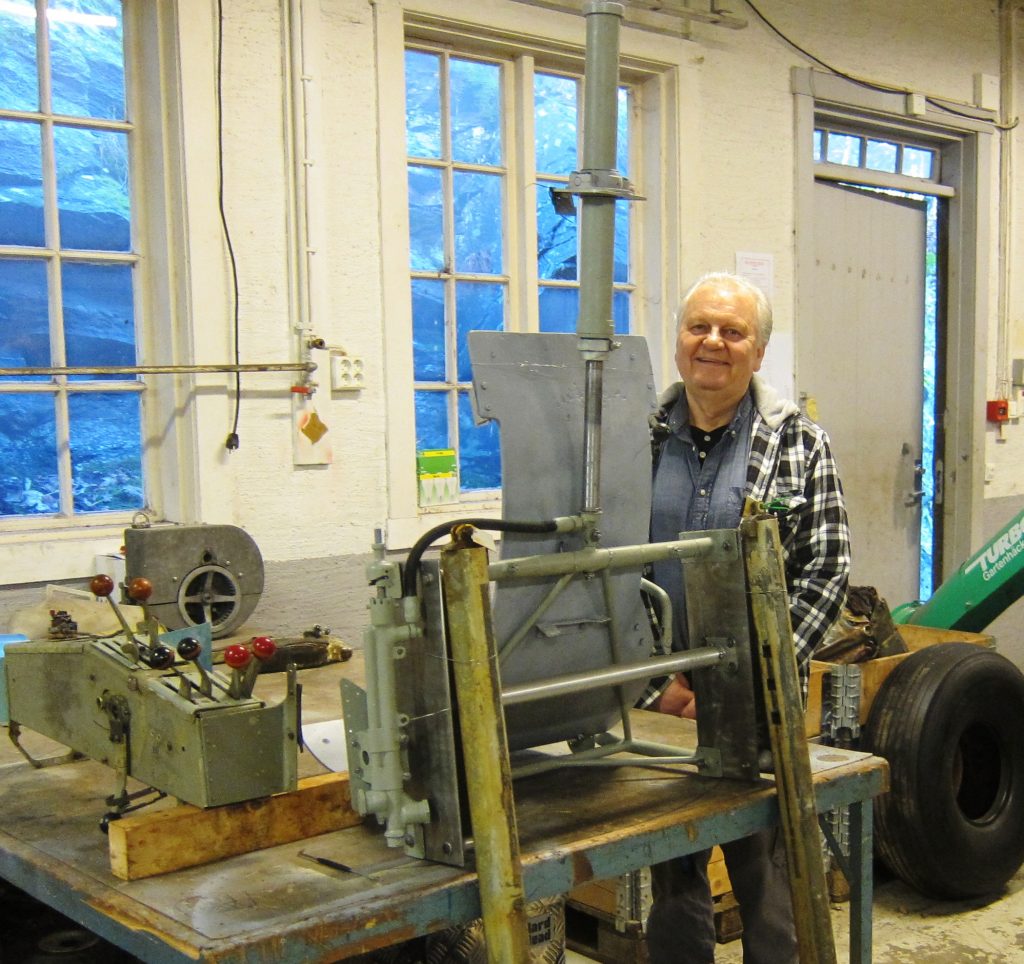

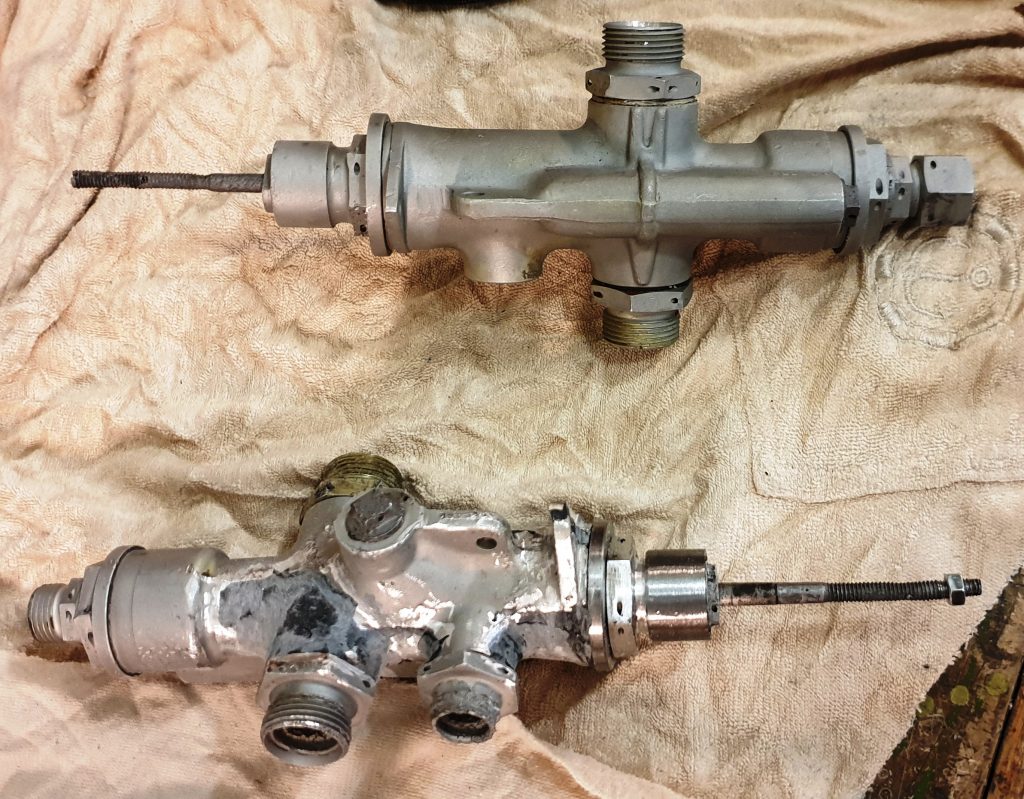

Et eksempel er

arbeidet som nå er ferdig med å bygge en ny hydraulikks håndpumpe for flap og

åpning av bombeluker m.m. Av den originale pumpen var det bare igjen håndtak, mekanisk

overføring til stempler, stempler og endelokkene. Nevnte deler er bygget av

høyverdige materialer og hadde klart seg godt nede på fjordbunnen. Hele

pumpehuset og sylindrene var derimot tilnærmet helt korrodert bort. Pumpe hus og sylindrer er nå blitt gjenoppbygd

og pumpen kan nå igjen brukes til å pumpe olje. De oven for nevnte gjenværende

deler er blitt integrert i den nye pumpen.

Det er også

gjennom året laget et nytt instrumentpanel til cockpit. Selv om det meste av

det originale panelet var borte da flyet ble hevet, vil likevel det nye panelet

bli utstyrt med originale instrumenter. Dette er instrumenter som ble funnet i

flyet og som nå er blitt konservert og i noen tilfeller delvis gjenoppbygd.

Gjennom

arbeidet med instrumentene har vi samtidig skaffet oss en god oversikt over

hvilke instrumenter og annet tilsvarende utstyr som har vært i flyets cockpit

og neseseksjon.

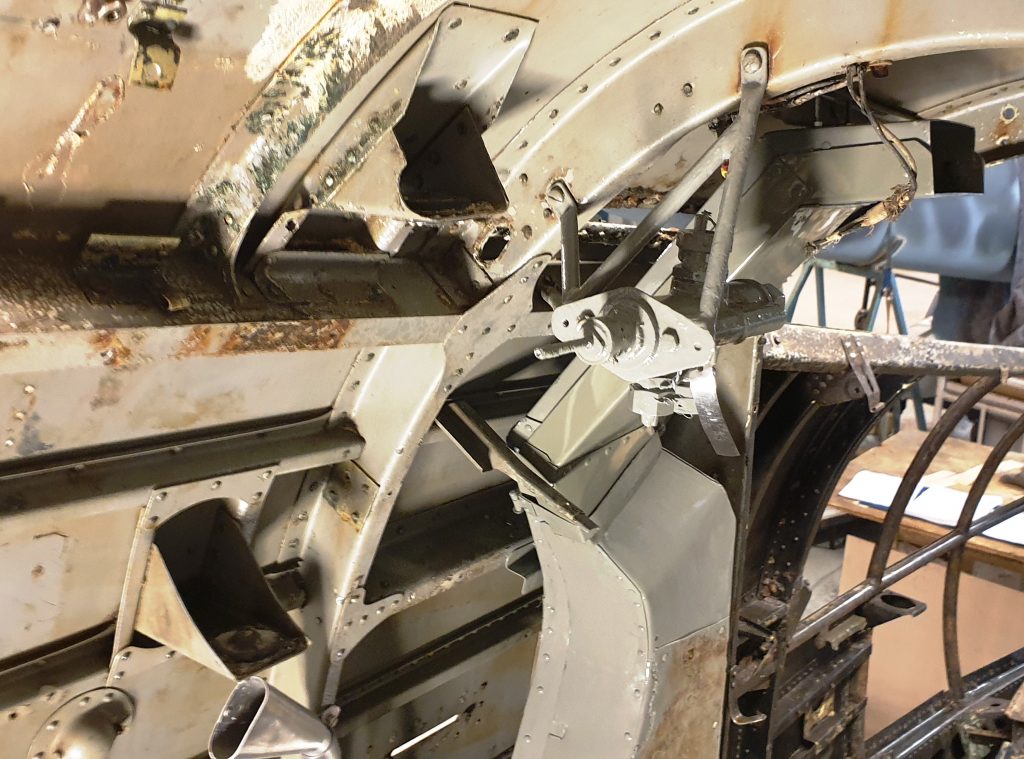

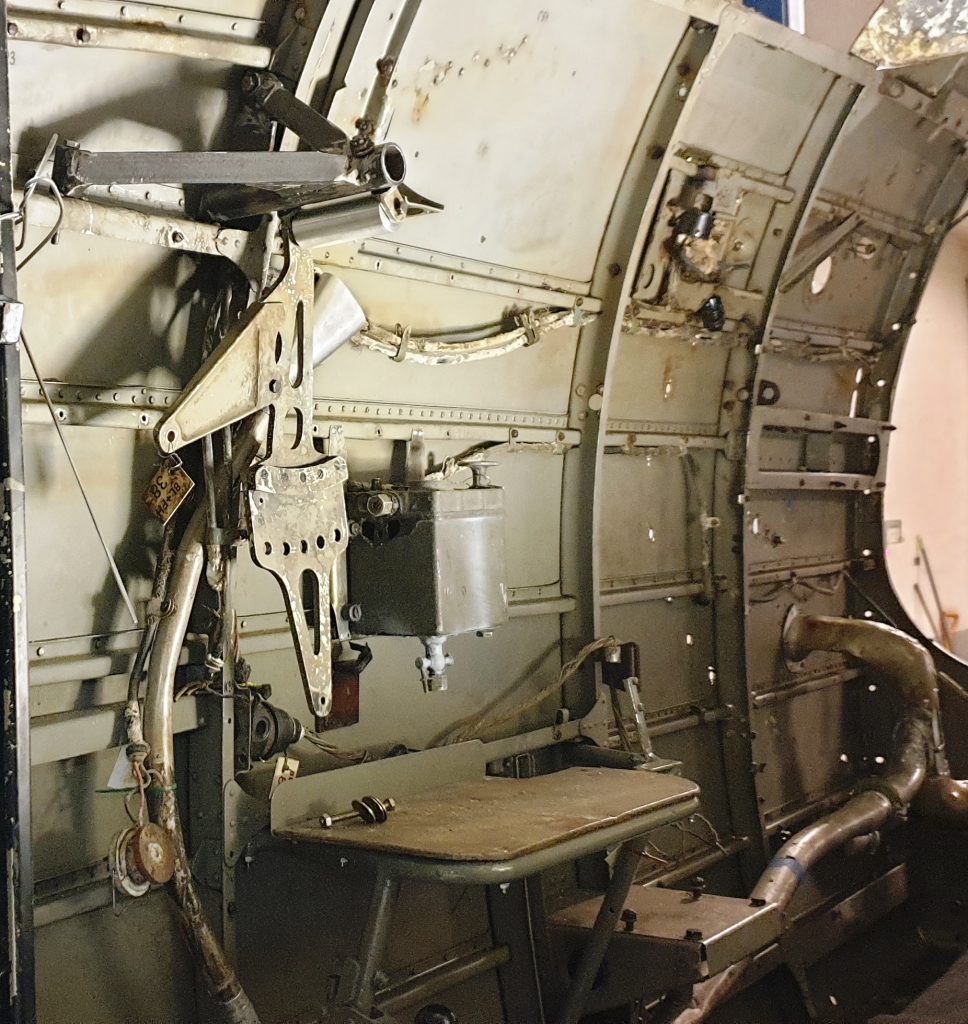

Et annen av

de større tingene som er blitt gjort gjennom 2020 er arbeidet med å gjenoppbygge

systemet for oppheng og overføringer fra siderors og tå pedalene. Også her er gjenværende

originale deler blitt integrert i det nye ferdige produktet.

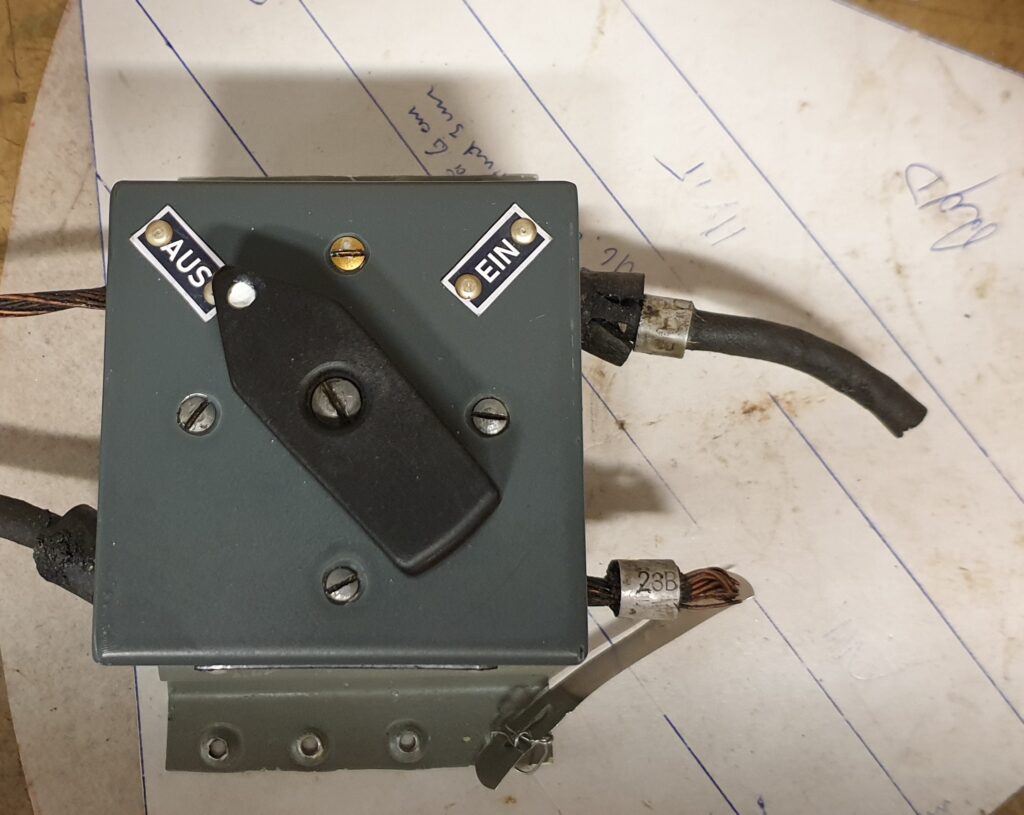

Det er også blitt

jobbet mye med å konservere originalt elektrisk utstyr. Dette er ting som automatsikringer,

brytere, rekkeklemmer og mange andre mindre elektriske komponenter. Arbeidet er

et tidkrevende tålmodighetsarbeid som nå virkelig begynner å vise igjen i form

av ferdig konserverte deler. Disse er enten allerede er blitt montert tilbake i

flyet, eller ligger på lager klar for bruk..

Den store og

omfattende kabelgaten langs babord side av cockpiten ble også ferdig tidlig i

2020

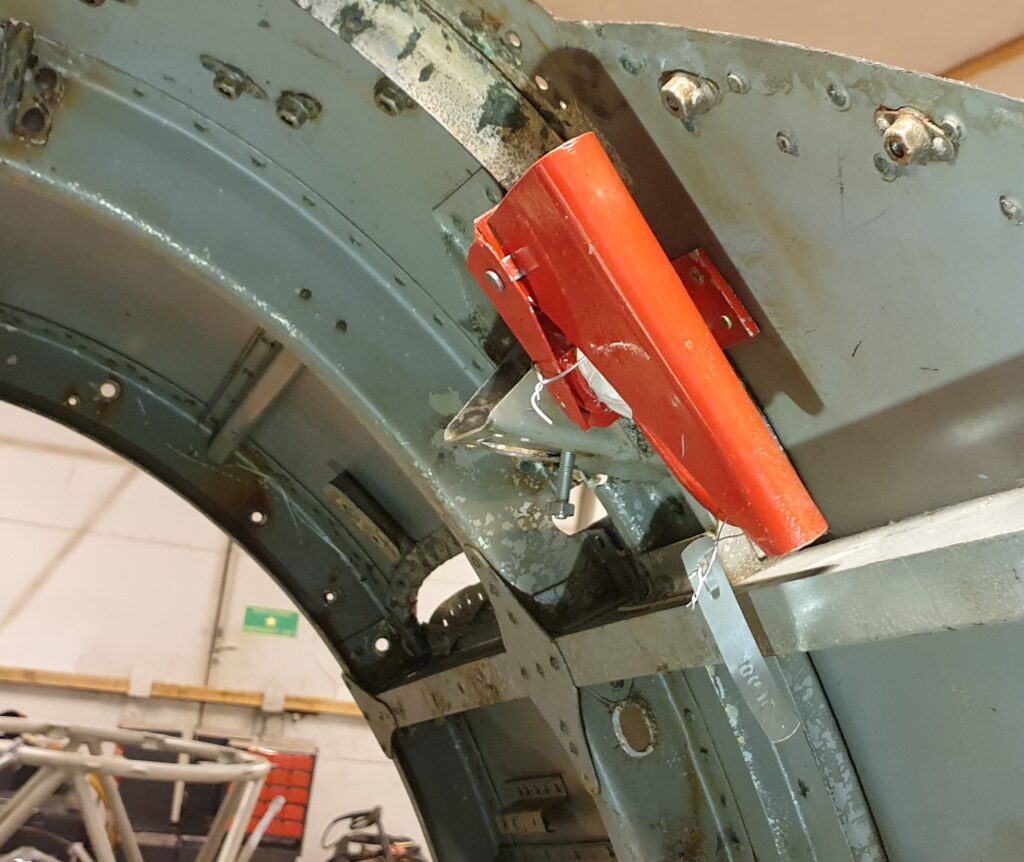

Den ytre

seksjonen av den ene motorbukken manglet helt da flyet ble hevet i juni 2012.

Dette fordi at den ene motoren ble berget før flyet sank i desember 1942. Den

manglende seksjonen er i løpet av høsten blitt bygd ny. Samtidig har det vi har

av originale braketter og annet utstyr til motorbukkene blitt tilbake montert

på motorbukkene.

Foto dele arkiv

og dokumentasjon er en tidskrevende oppgave som løper så lenge som prosjektet

pågår. Det er også gjennom 2020 blitt jobbet mye med disse tingene.

Da flyet ble

hevet i juni 2012 ble noen få mindre deler liggende igjen på funnstedet. Det ble

i året som gikk gjort flere ROV dykk på havaristedet i Hafsfjord. Selv om flyet var uvanlig komplett til

sjøvrak å være, manglet også vårt fly ting som ikke lar seg oppdrive andre steder.

Det er derfor sendt en ny søknad om å få heve He 115 deler fra Limingen.