Vinteren og våren 2024 har nesten alt arbeid på Flyhistorisk Museum Sola vært konsentrert rundt arbeidet med å ferdigstille de nye utstillingene. Museet har fått bygget en ny stor utstillingshall, samt et nytt bygg som skal ivareta behovet for en ordentlig resepsjon med kafeteria og toalett fasiliteter. Det har for museet vært en meget arbeidskrevende prosess å flytte rundt på fly og annet som tilhører utstillingene. Alt arbeidet er gjort i form av frivillig innsats fra museets medlemmer.

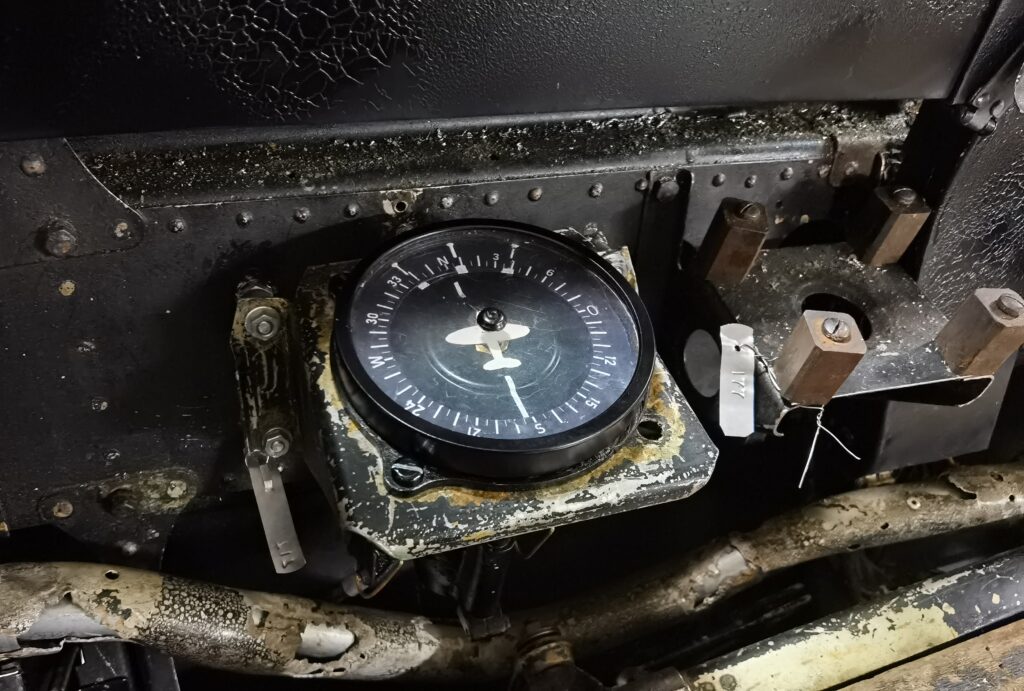

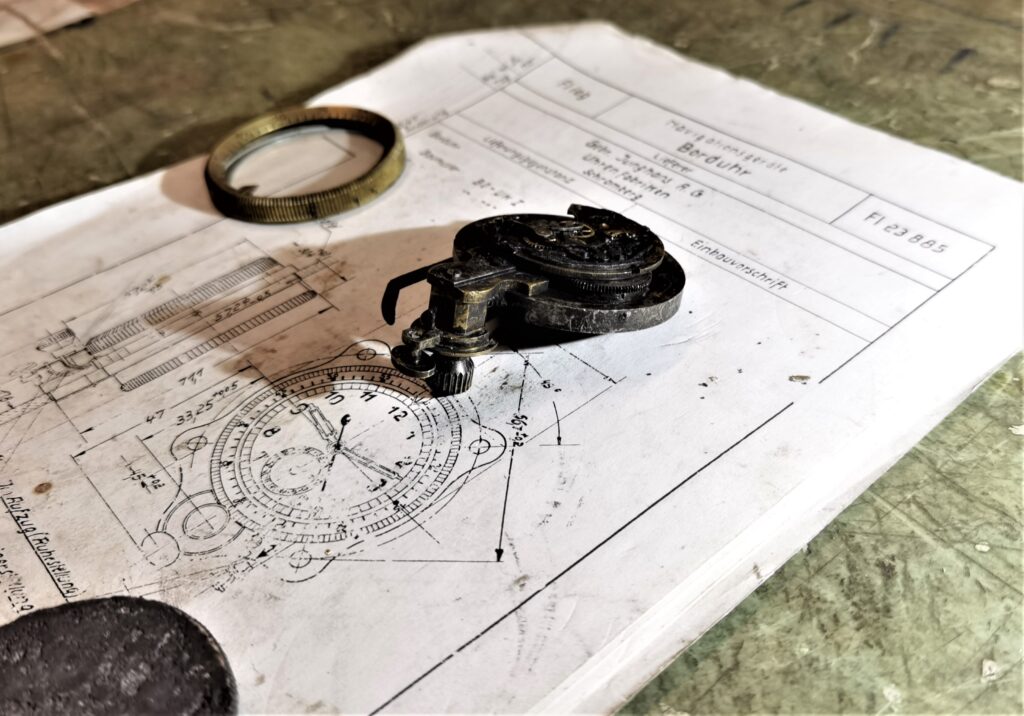

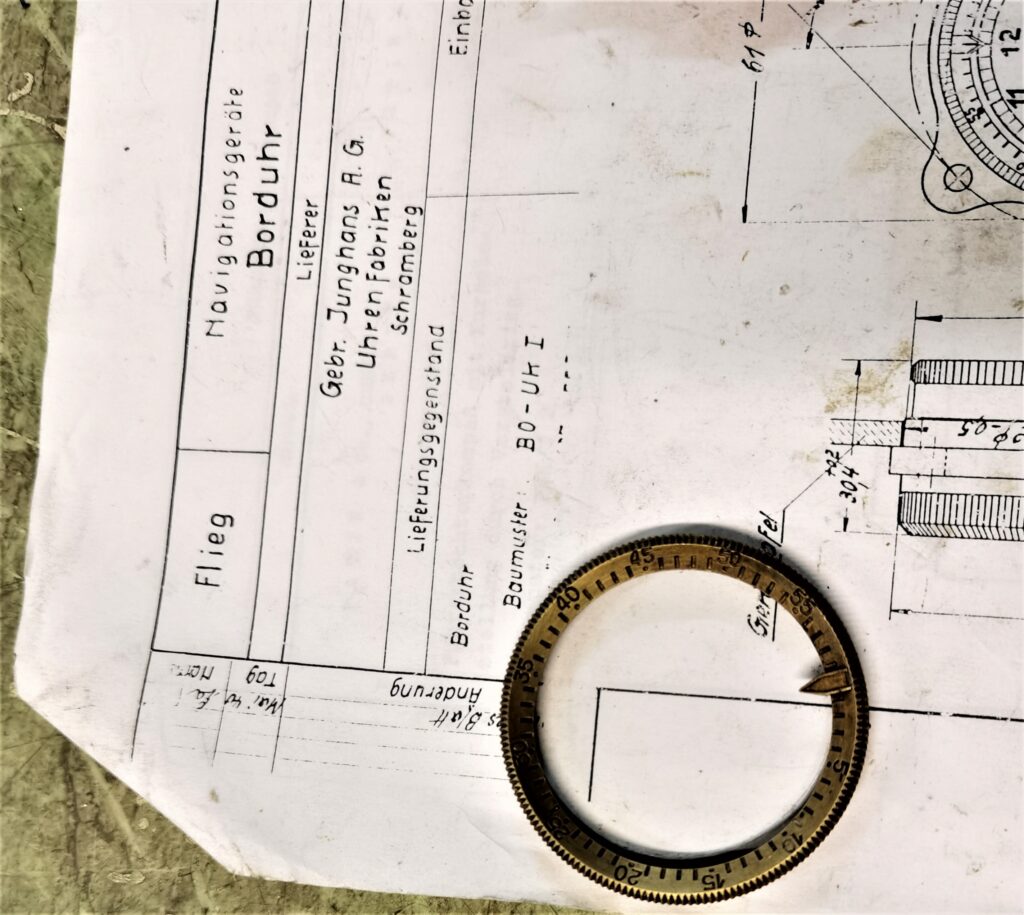

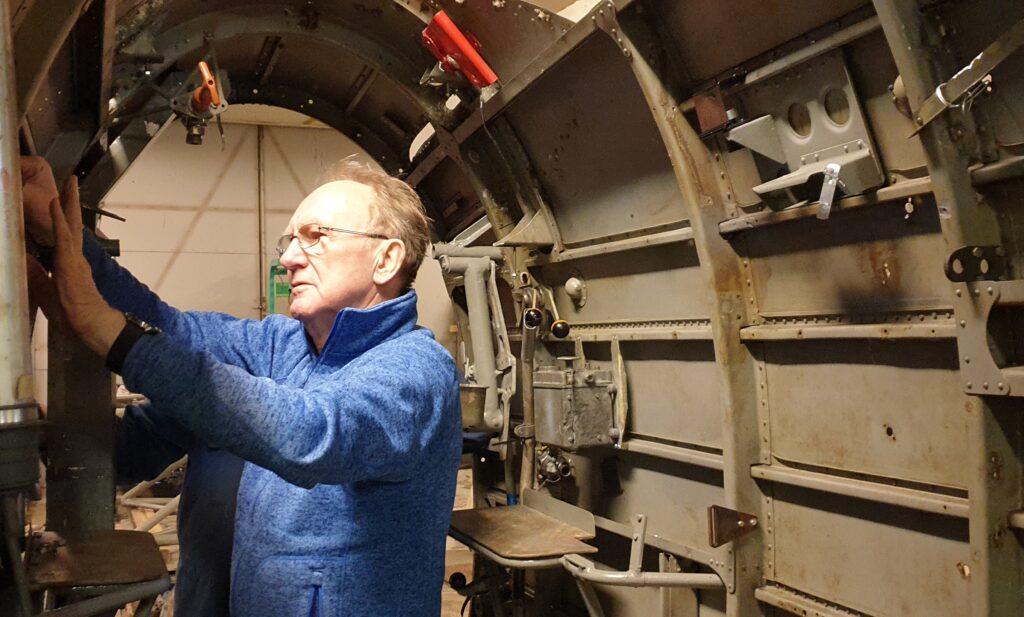

Arbeidet med utstillingene har i en stor grad gått på bekostning av arbeidet med restaureringsprosjektene. Dette gjelder også for Heinkel 115 prosjektet. Derfor har lite nytt skjedd denne våren med arbeidet vi planlegger å gjøre på senterseksjonen. Likevel har det pågått et kontinuerlig arbeid med å tilbake montere komponenter i cockpit og Kanzel. Det har og blitt arbeidet med å konservere deler som vi ikke har rukket å gjøre klar for videre bruk.

Vi vil etter sommerferien igjen starte opp arbeidet på senterseksjonen.

Vi har i mai måned hatt gleden av to besøk av langveis reisende.

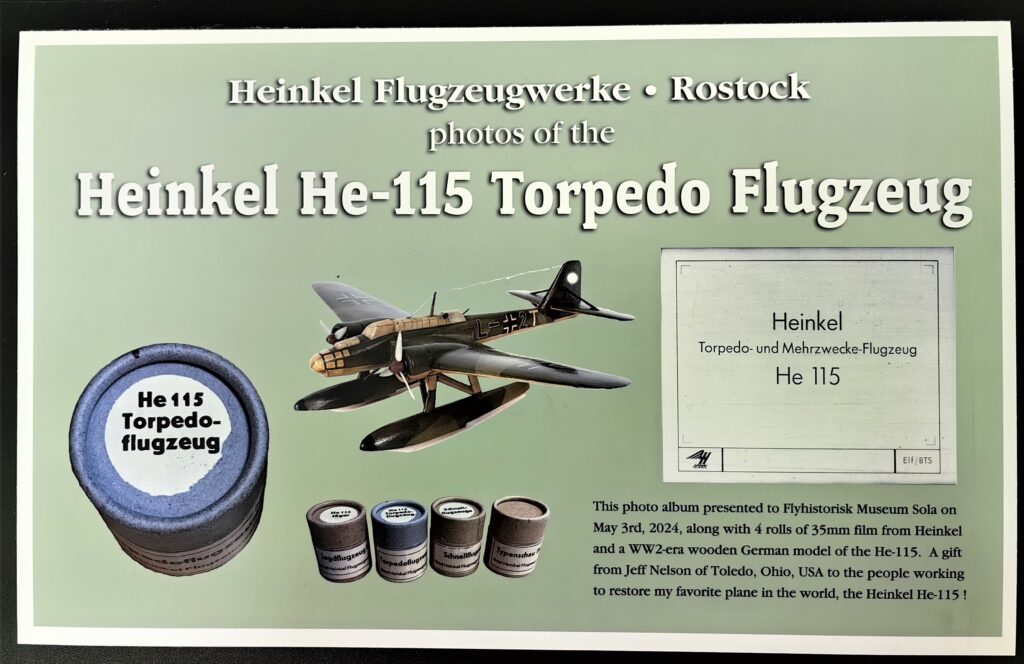

Jeff Nelson, sammen med venner fra både USA og Tyskland, besøkte 4 mai museet for å se Heinkel 115. Jeff donerte museet en rekke flotte og verdifulle presanger. Vi er både imponert av og ydmyke for det faktum at noen vil gi oss en så stor oppmerksomhet som det er å reise så langt for å besøke oss.

31. mai var det Andrew Frauenfelder som sammen med ektefelle besøkte oss for å se på flyet. Ekteparet er bosatt i USA. Andrew besitter en omfattende kunnskap om historien og bruken av Heinkel 115.