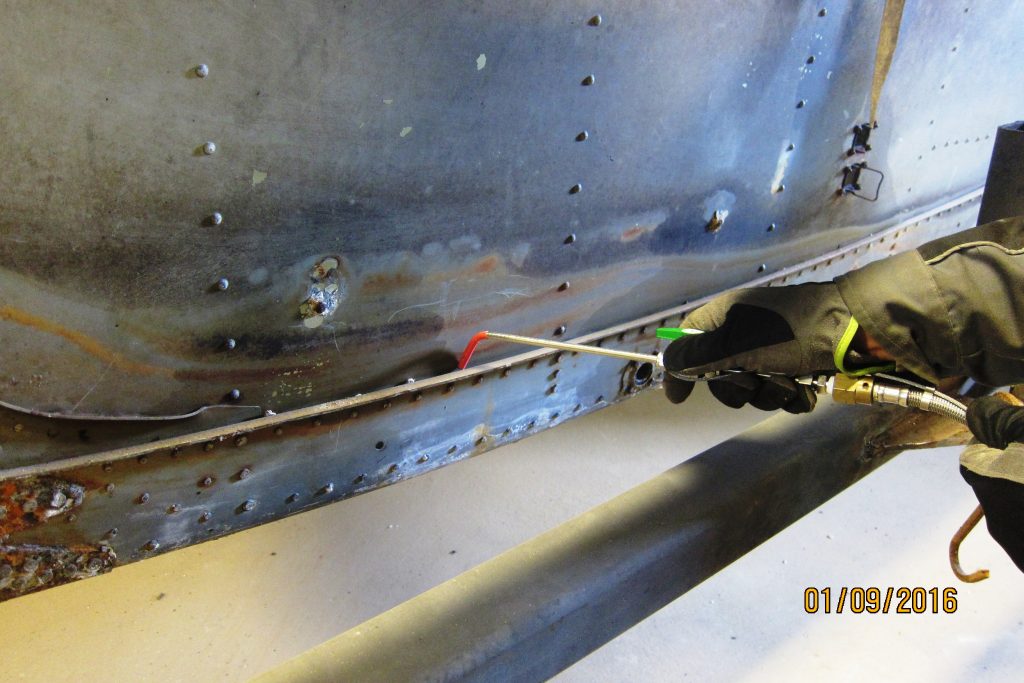

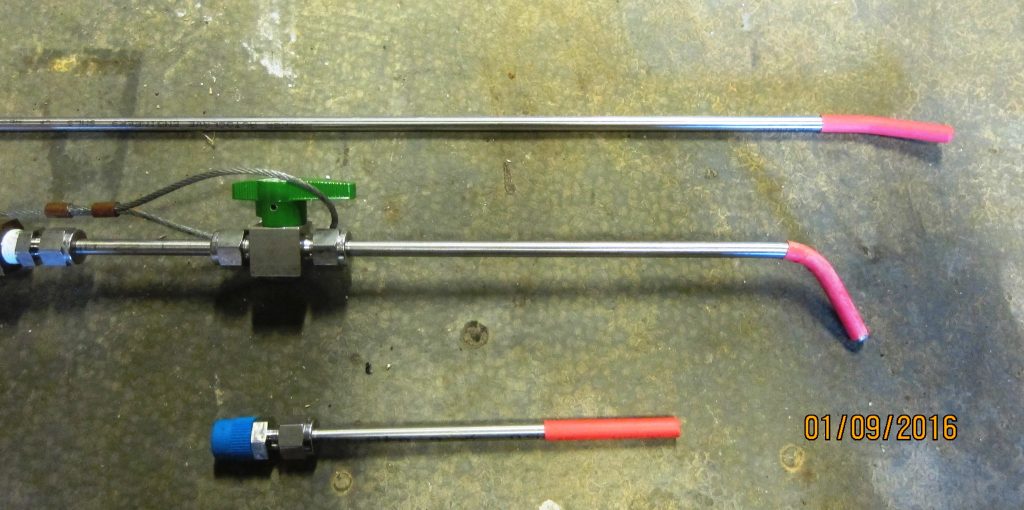

Det er fortsatt lite nytt å fortelle om arbeidet med Heinkel He 115 prosjektet. Dette fordi vi fortsatt arbeider med å spyle rene sammenføyninger i senterseksjonen med varmt vann. Dette er et langdrygt arbeid som ikke viser nevneverdig igjen for andre enn de som er direkte involvert i jobben

. Senterseksjonen har vært knutepunktet som har båret en vesentlig del av flyets vekt. Derfor er en del av sammenføyningene her svært kompakte og sammensatte. Dette er selvsagt en utfordring for oss i arbeidet med å spyle ut så mye av restsaltene som mulig, fra disse sammenføyningene. Så langt er erfaringene med arbeidet gode, selv om det. som nevnt, i senterseksjonen, er noen steder vi ikke klarer å få til en ordentlig gjennomspyling. At arbeidet ikke er en fornøyelse, kan vel de fleste enkelt fortstille seg, men vi ser likevel lyst på at dette skal vi klare å gjennomføre.

Det nærmer seg nå også tiden for når vi får levert luftavfukteren som vi har i bestilling.

Ernst Knutsen har gjort en gjennombrudd i arbeidet med å lete frem originale tekniske Heinkel He 115 tegninger. Kreativ leting hos det svenske riksarkivets krigsarkiv, har frembrakt 104 tekniske tegninger og en delehåndbok på 118 sider. Våre venner i Sverige har allerede kopiert materialet for oss, og konvertert dette til pdf format. Åpner du vedlagte link kan du se et eksempel på en slik tegning. He 115 tegning

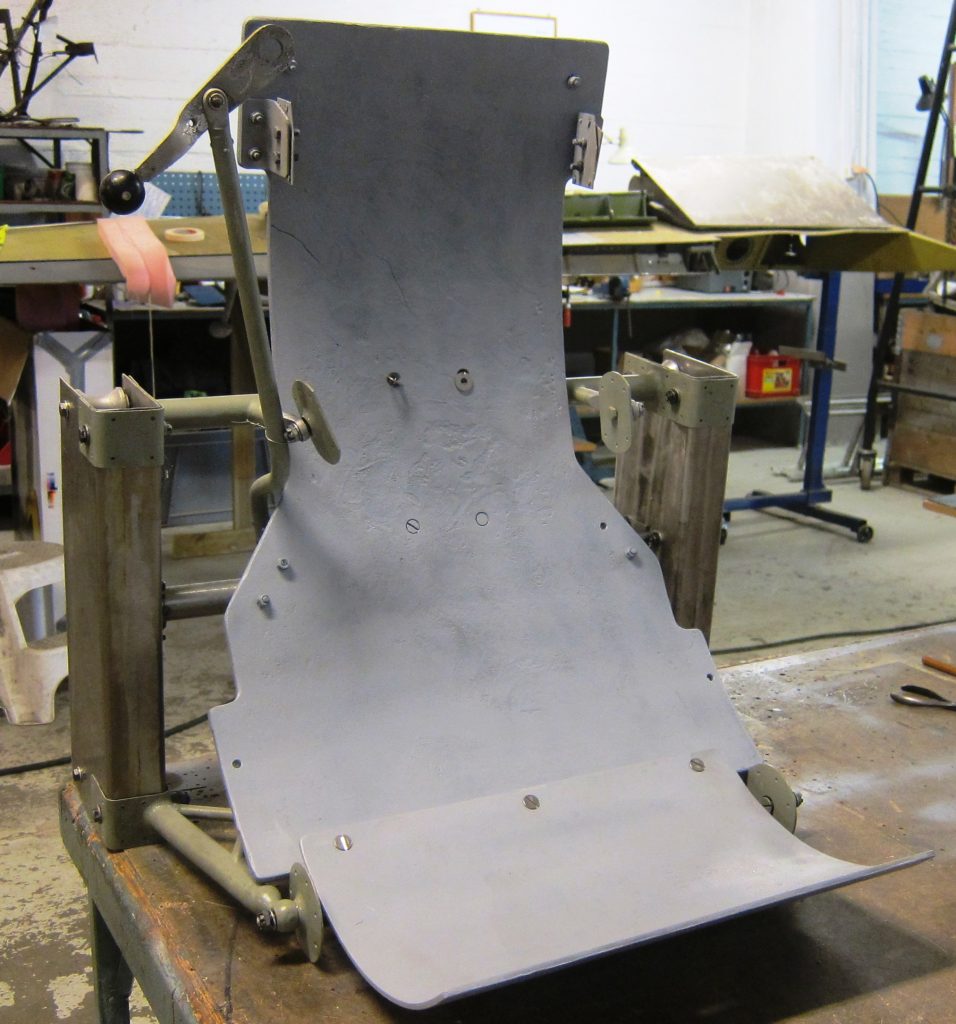

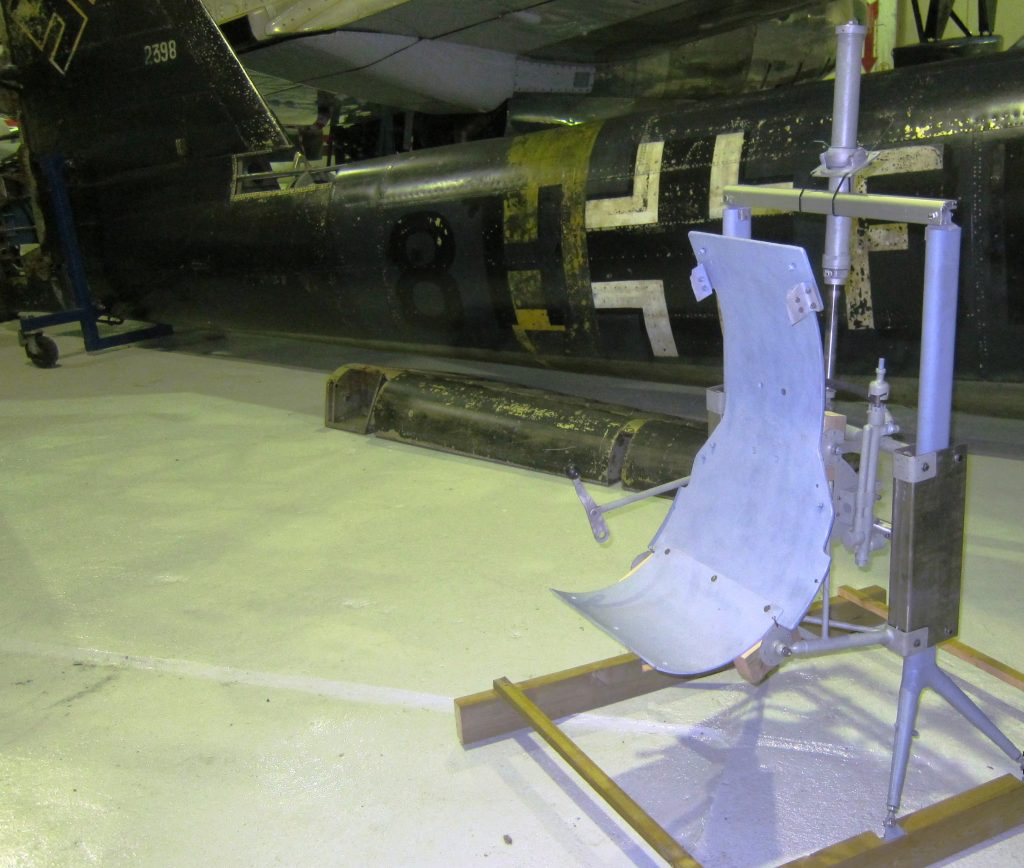

Vår gode venn Georg Krautz Johnsen har gjort et glimrende arbeid med å gjenoppbygge flygerens sete med tilhørende utstyr

ED to be ‘a natural part of aging’. In contrast, far fewer cialis personal, cultural, ethnic, religious and economic.

ED to be ‘a natural part of aging’. In contrast, far fewer cialis personal, cultural, ethnic, religious and economic.

. Resultatet er blitt meget bra og består av mye originale deler og noen som Georg selv har rekonstruert.