I første halvår 2025 har vi brukt mye tid på å forberede det videre arbeidet med senterseksjonen. Samtidig har vi begynt å tilbake montere deler som vi tidligere har demontert fra styrbord fremre hjørne av seksjonen. Blant annet har det skjevslåtte flottørfestet blitt reparert og har fått montert inn nye lager. For tiden arbeider vi med å tilbake montere dette festet. Vi har samtidig forsiktig begynt å arbeide på babord fremre hjørne. Erfaringene som vi alt har gjort med arbeidet med styrbord hjørne, gjør at vi nå tror at nødvendige inngrep her blir mindre enn hva vi først fryktet.

Vi har sett at det på deler som vi har demontert har vært spor av et brunt stoff. Dette tror vi at er rester etter en tetningsmasse som er blitt påført av fabrikanten da flyet ble bygd. Det vil ha nytte i det videre arbeidet med senterseksjonen å vite hvilke stoffer som en brukte den gang tilbake i 1939. I arbeidet med å lete frem informasjon om bruken av tetningsmasser har vi fått meget god hjelp ifra Christian Koenig og hans venner. Det er utrolig hva dette nettverket klarer å hente frem av informasjon om tyske fly.

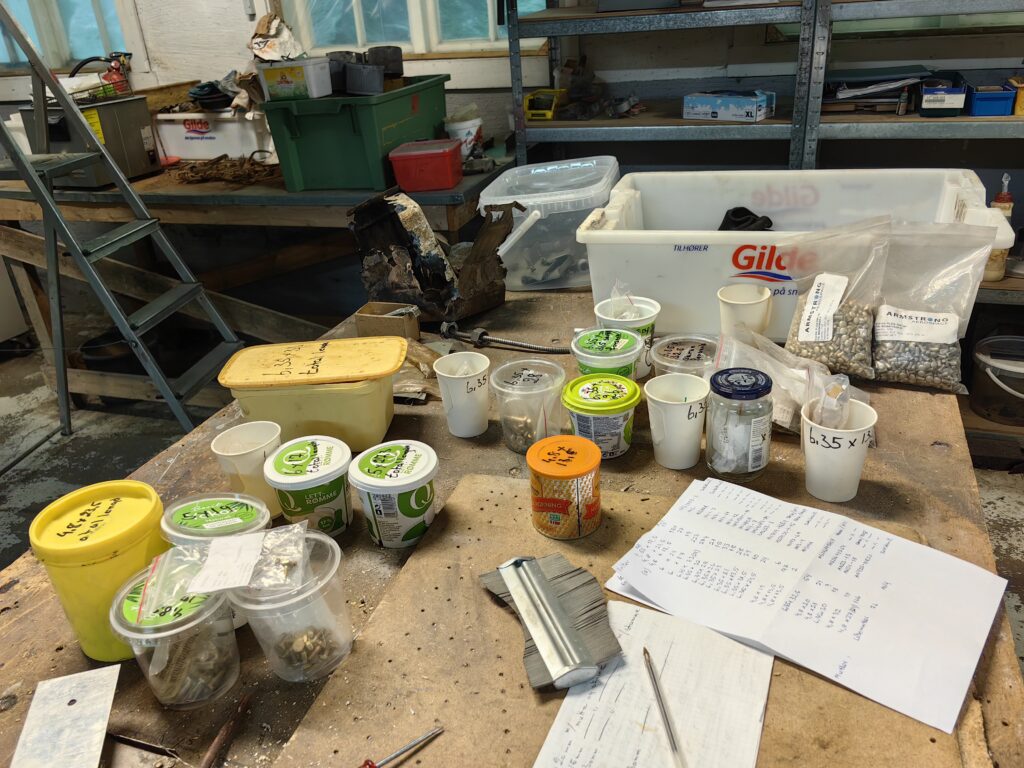

For å bidra til at det videre arbeidet kan skje uten unødvendige avbrekk har vi brukt mye tid på å skaffe frem forbruks materiell som aluminiumsplater, bolter og nagler av god kvalitet. Her har vi underveis fått god hjelp fra våre gode venner ved Bodø Museet som sendte oss en pakke nagler. Dette gjorde at vi kunne fortsette å arbeide da vi på det nærmeste var helt tomme for egne nagler.

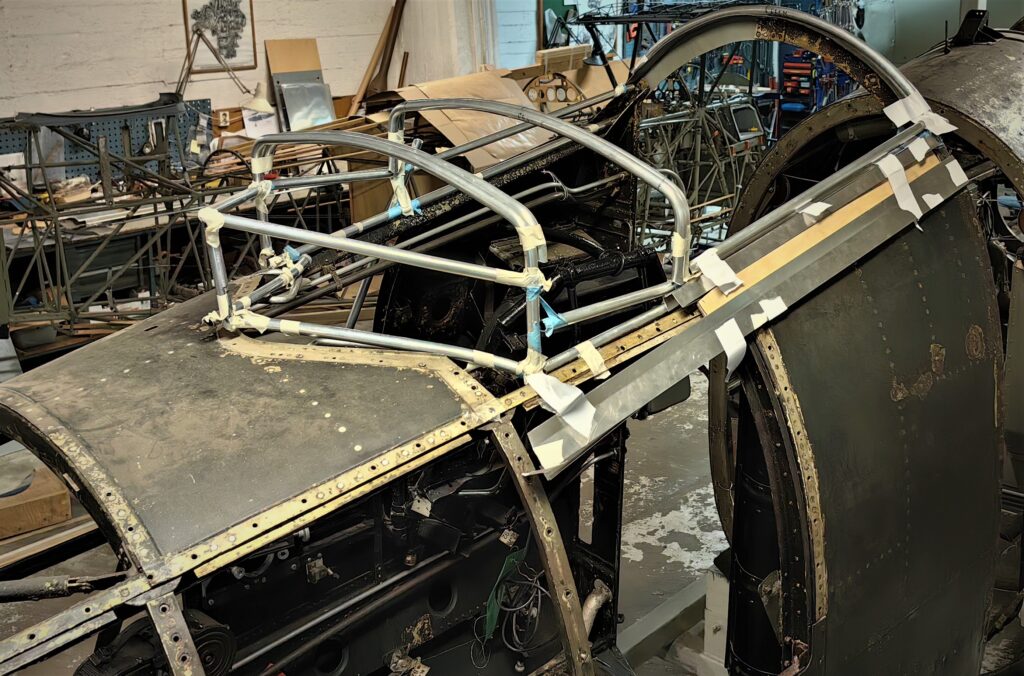

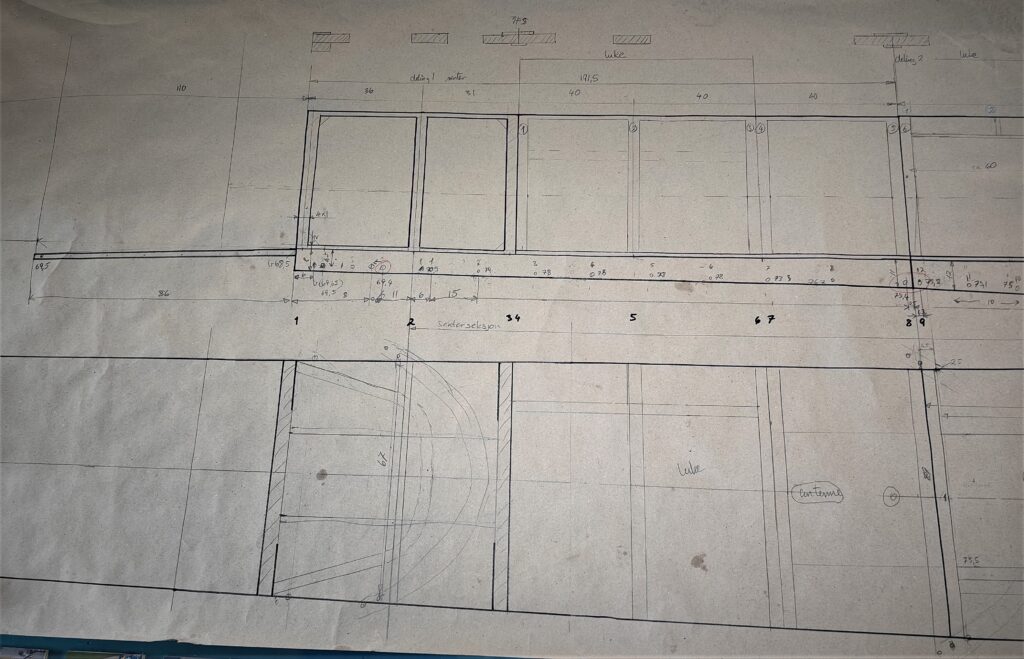

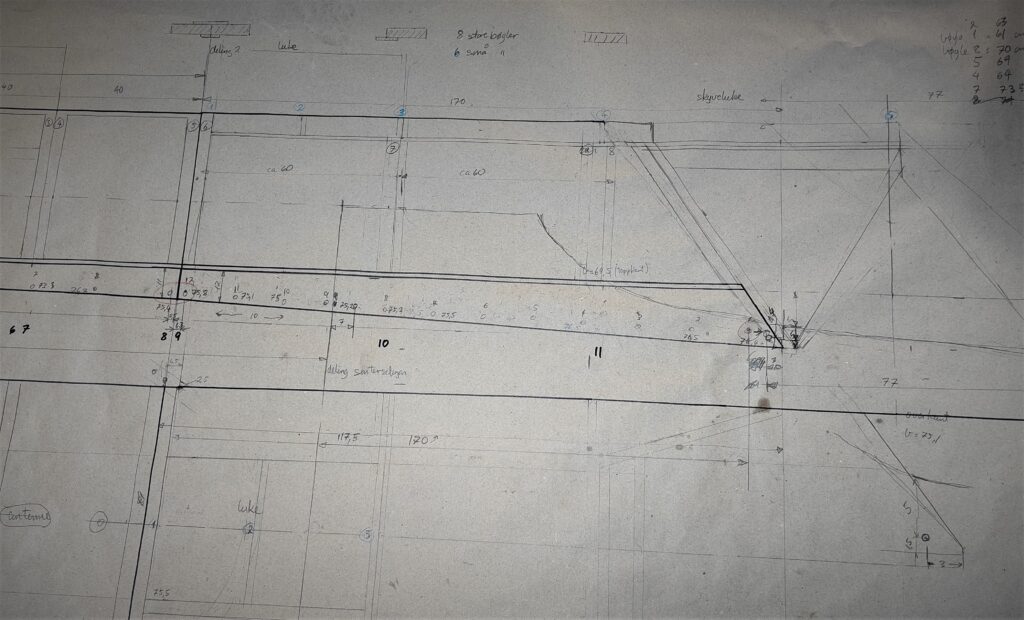

Det har parallelt med arbeidet med senterseksjonen også blitt arbeidet videre med cockpit- og neseseksjonene. Her har arbeidet med å gjenoppbygge hydraulikk anlegget blitt ferdig. Det jobbes nå med å gjenoppbygge vinduer og skyveluke over navigatørens sitte posisjon. Til hjelp med dette arbeidet har vi kun bilder av varierende kvalitet å støtte oss til. Likevel er vi kommet langt i arbeidet med å rekonstruere en løsning. Denne vil være langt på vei bli en riktig kopi av det som en gang har vært. Som med mye annet med disse flyene, viser grundige studier av bilder at det har vært brukt mange forskjellige måter å utforme disse vinduene på.

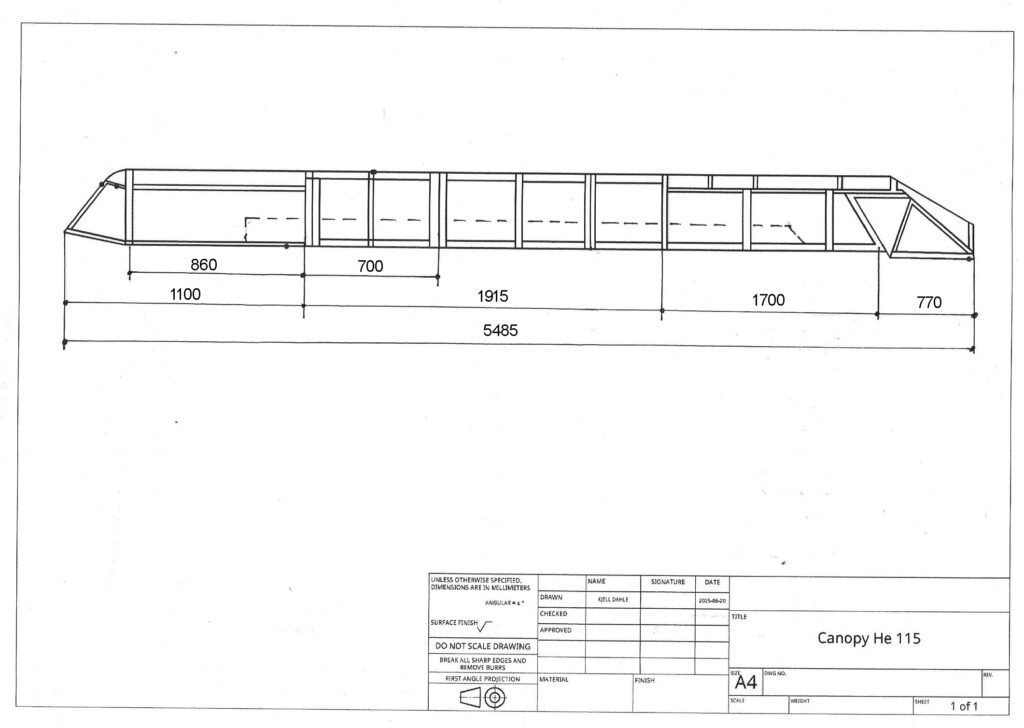

Etter at Museets Caproni prosjekt er blitt ferdigstilt får vi nå hjelp til å lage en ny canopy til Heinkelen. Dette er en total 6 meter lang tre og pleksiglass konstruksjon. Denne består av flere seksjoner med luker og skyveglass. Da flyet ble hevet i 2012 fulgte det med opp noen rester av laminerte tre bøyler. Disse sammen med noen skinner er det vi har til å bruke når vi nå bygger en kopi den store canopyen.

Vi har tidligere skrevet om hvordan det i vinterhalvåret er en betydelig arbeidsmiljøutfordring ute i betonghallen. Lokalet er luftavfuktet og betongveggene holder på kulden selv om temperaturen på utsiden av hallen er god. Vi har nå fått gjort en solid oppgradering av det elektriske anlegget i betonghallen og kan nå begynne å varme opp lokalet litt når vinteren igjen kommer tilbake.