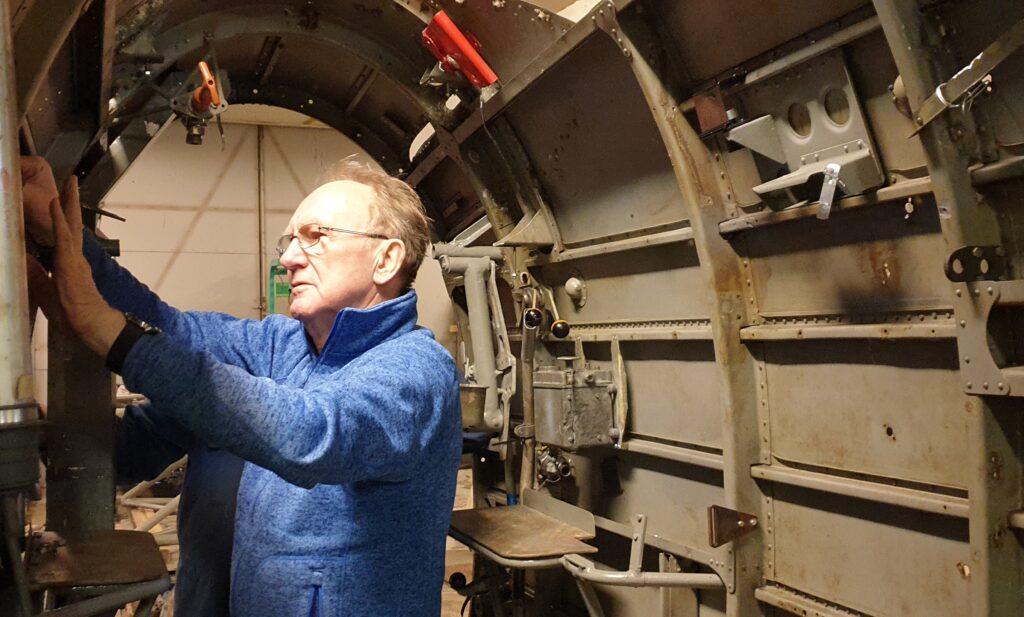

Vi har i det siste arbeidet mest med å klargjøre for å flytte senterseksjonen ut ifra betonghallen og inn på verkstedet. Dette fordi vi skal begynne på arbeidet med å utbedre lokale korrosjonsskader i senterseksjonen. Disse skadene er i hovedsak lokalisert til områdene innenfor vinge, flottør og motorfester. Dette vil bli et tidkrevende arbeid. Er vi heldige slipper vi å måtte gjøre andre og mer inngripende arbeider på senterseksjonen. Ultralyd undersøkelser, som IKM Inspection AS har gjort for, oss viser at det heldigvis er lite korrosjon på de mest kompliserte delene av bærestrukturen i senterseksjonen.

Senterseksjonen vil ta opp mye plass inne på verkstedet. For å få frigjort denne plassen, har det blitt prioritert å arbeide med Caproni neseseksjon. Dette siste har selvsagt fått noen følger for fremdriften i arbeidet med He 115 cockpit og neseseksjon. Den første flyttingen av senterseksjonen inne i betonghallen er nå unnagjort. Planen videre er nå er å sage ut en fem meter bred åpning i vest- veggen på betong hallen. Gjennom denne skal vi så trille senterseksjonen. Når senterseksjonen er ute av betonghallen, må vi umiddelbart lukke igjen åpningen i murveggen. Prosessen med å sage ut hullet i betongen, flytte ut senterseksjonen og så lukke igjen hullet i betongveggen må skje i løpet av en og samme dag. Dette planlegger vi å gjøre i løpet av høsten.

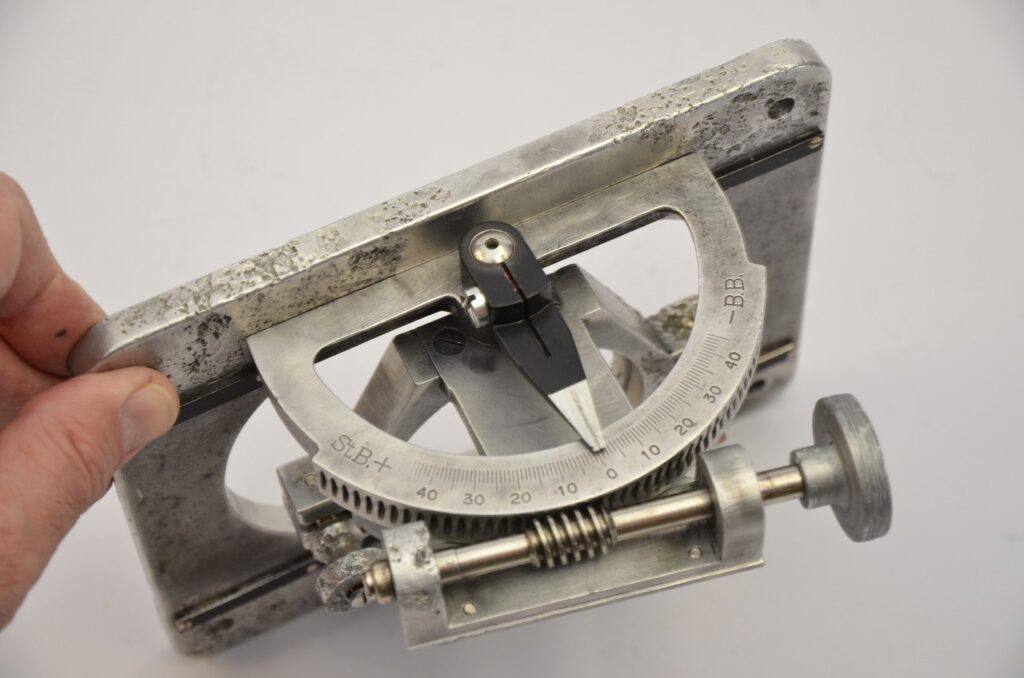

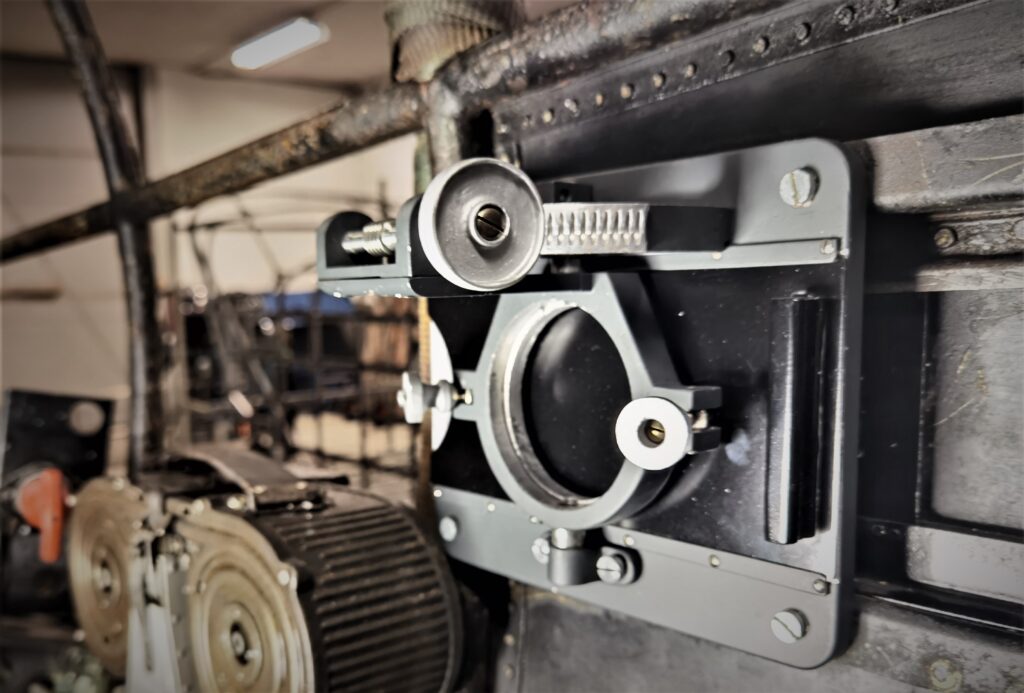

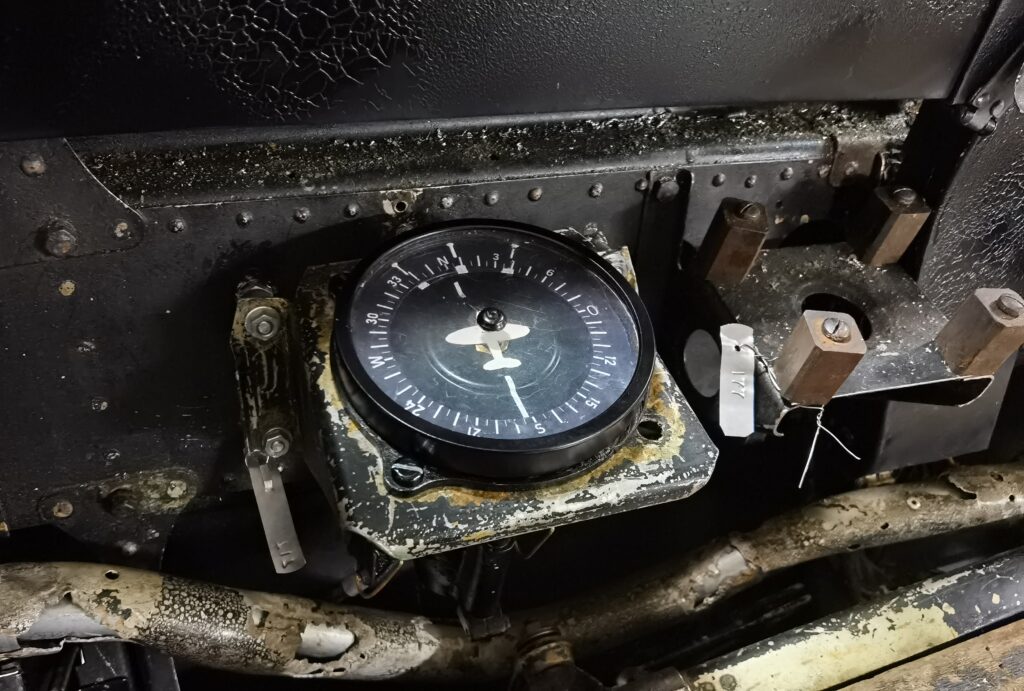

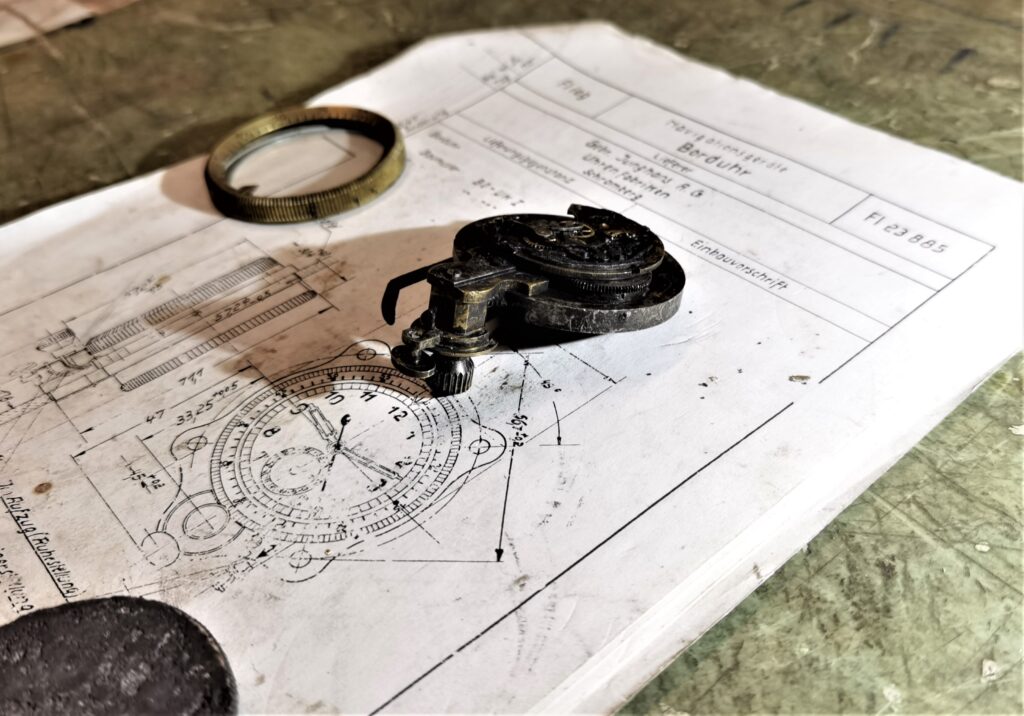

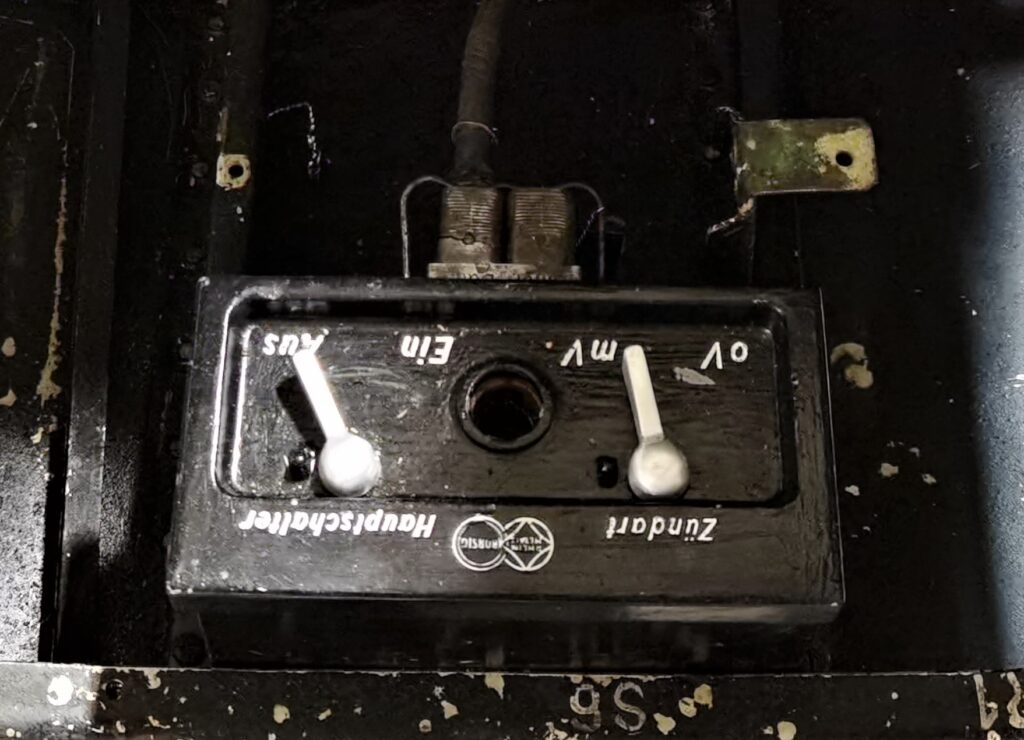

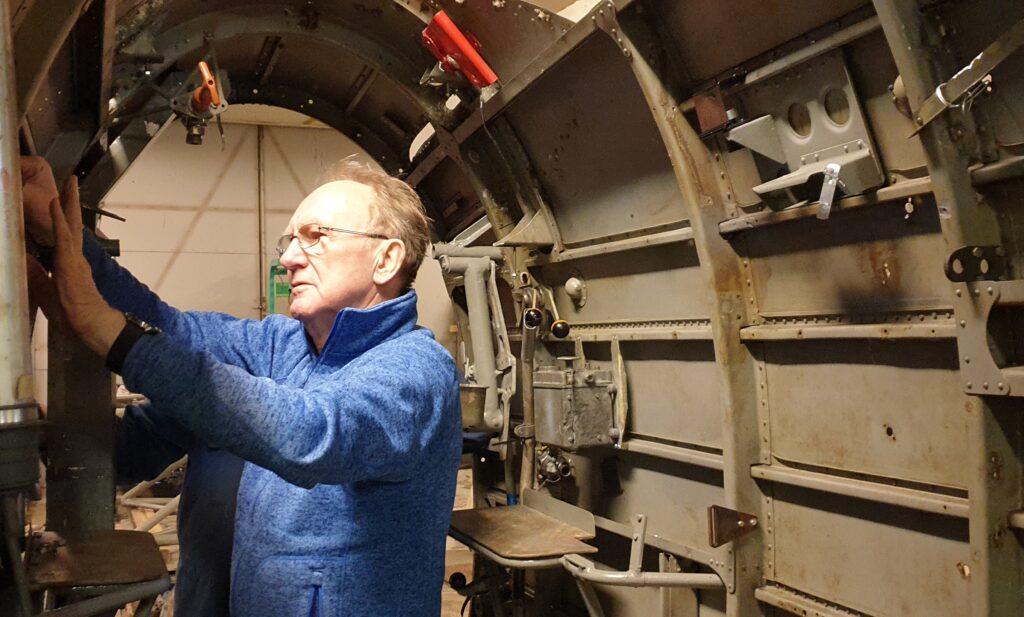

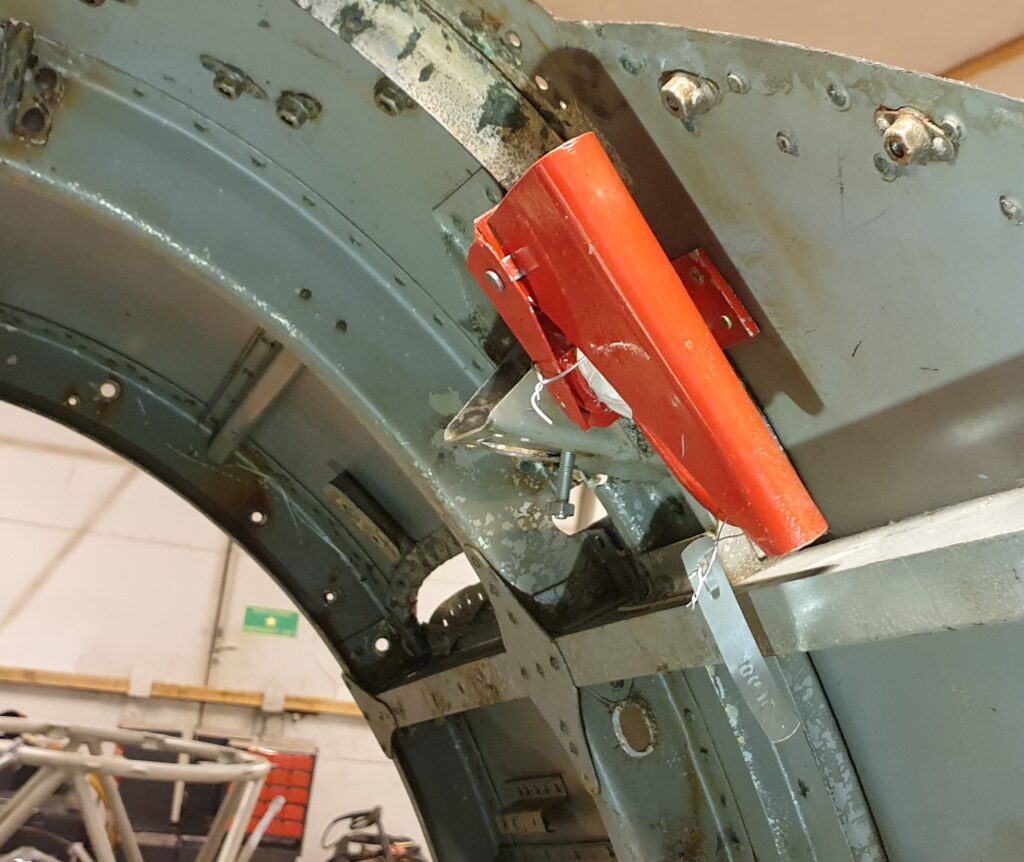

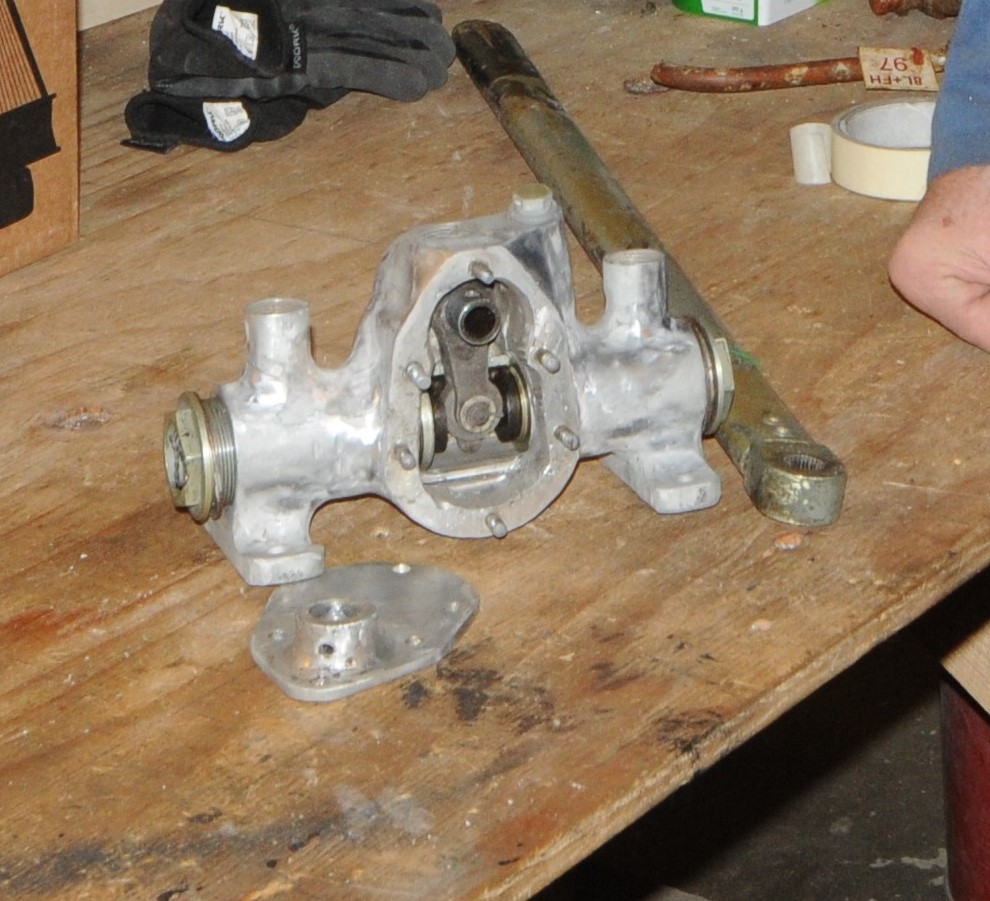

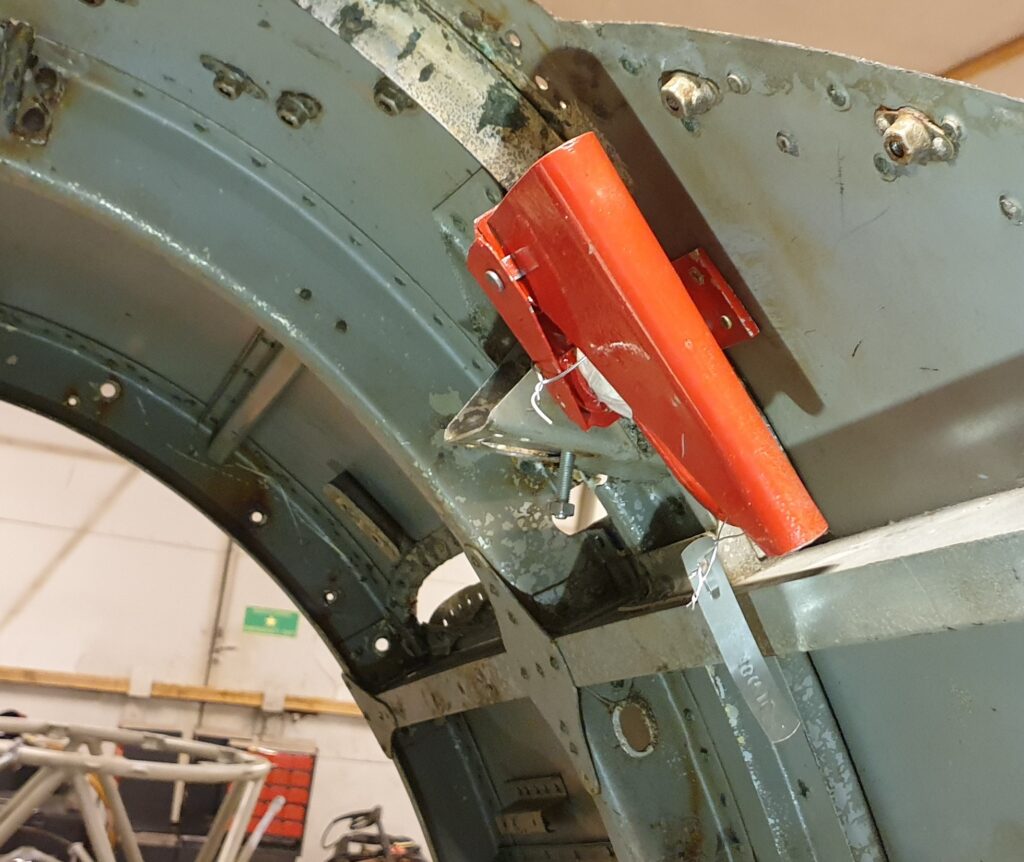

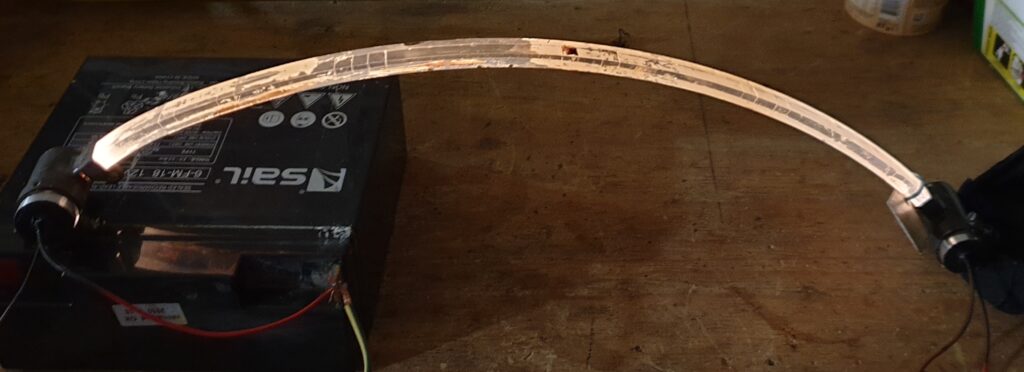

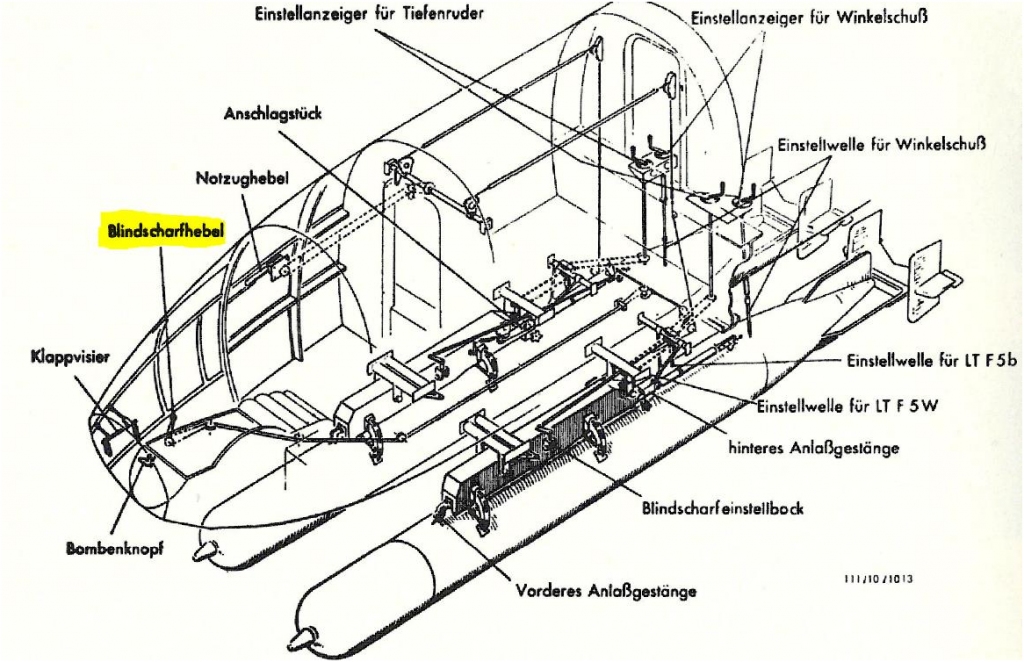

Da vi hevet flyet fant vi fremme i Kanzel deler av et måleinstrument som vi ikke forsto bruken av. At dette var deler av en avdriftsmåler forsto vi, men vi var usikre på hvordan denne hadde vært montert i flyet. Avdriftsmåleren ble da gitt en midlertidig konservering og så lagt på lager. På styrbord side fremme i Kanzel er det en rektangulær luke. Bak denne luken fant vi rester av en magnesiums brakett og rester av en tøy mansjett. Vi forsto ikke hva denne luken og braketten var blitt brukt til. På bilder av Heinkel 115 vises denne luken, med få unntak, som stengt.

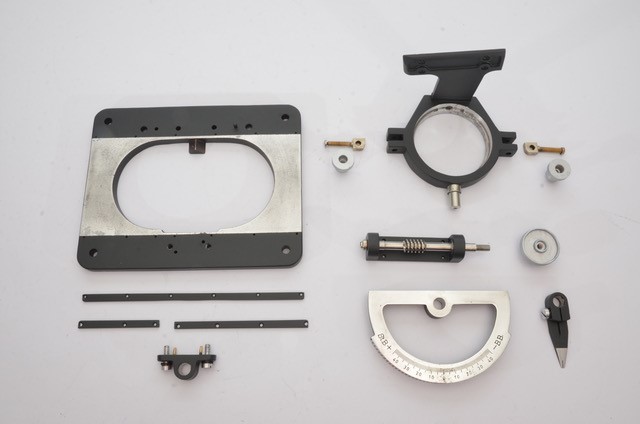

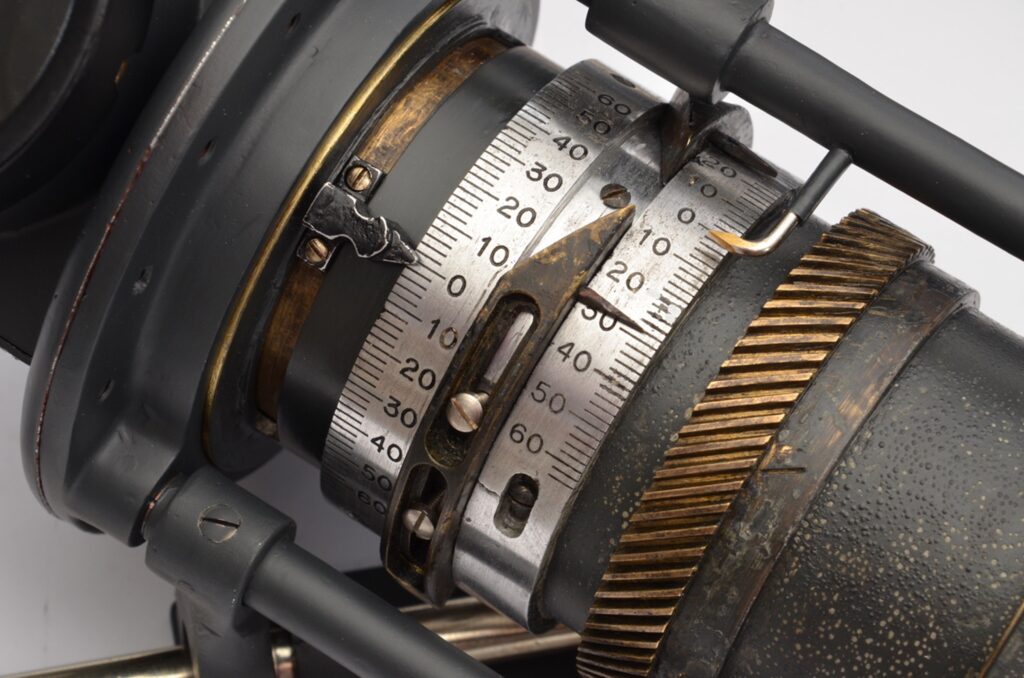

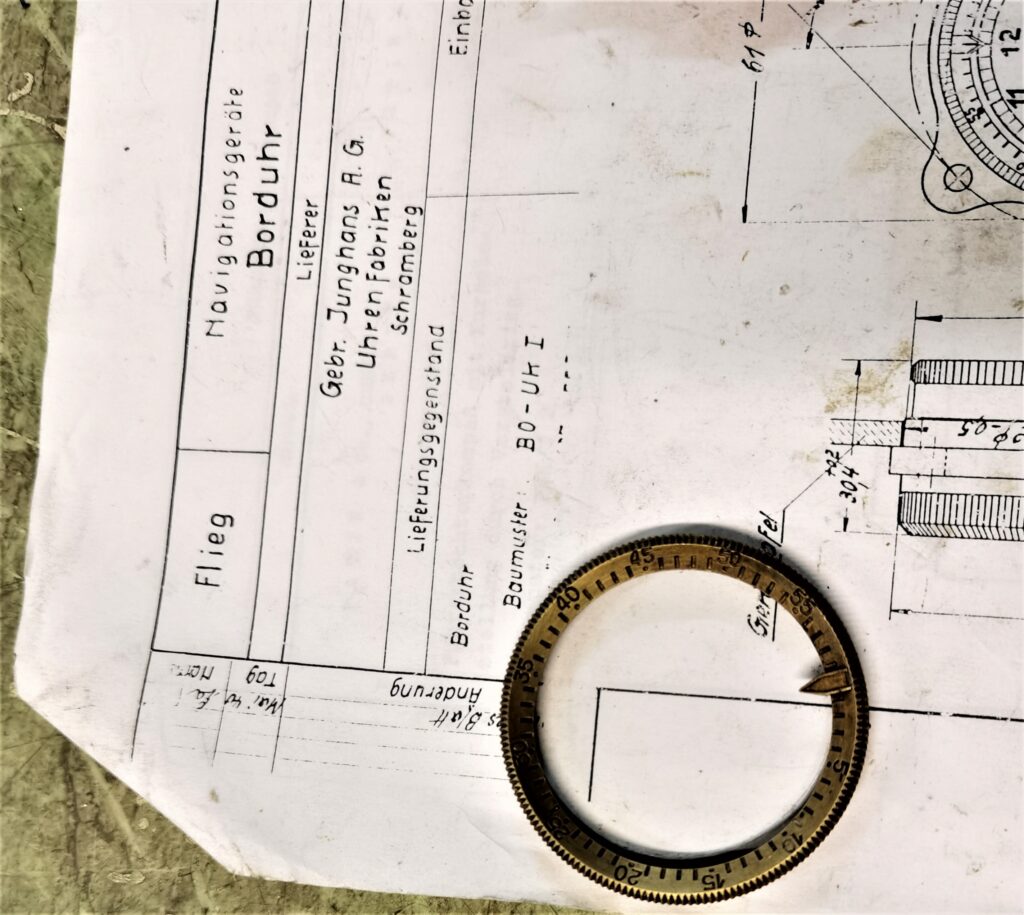

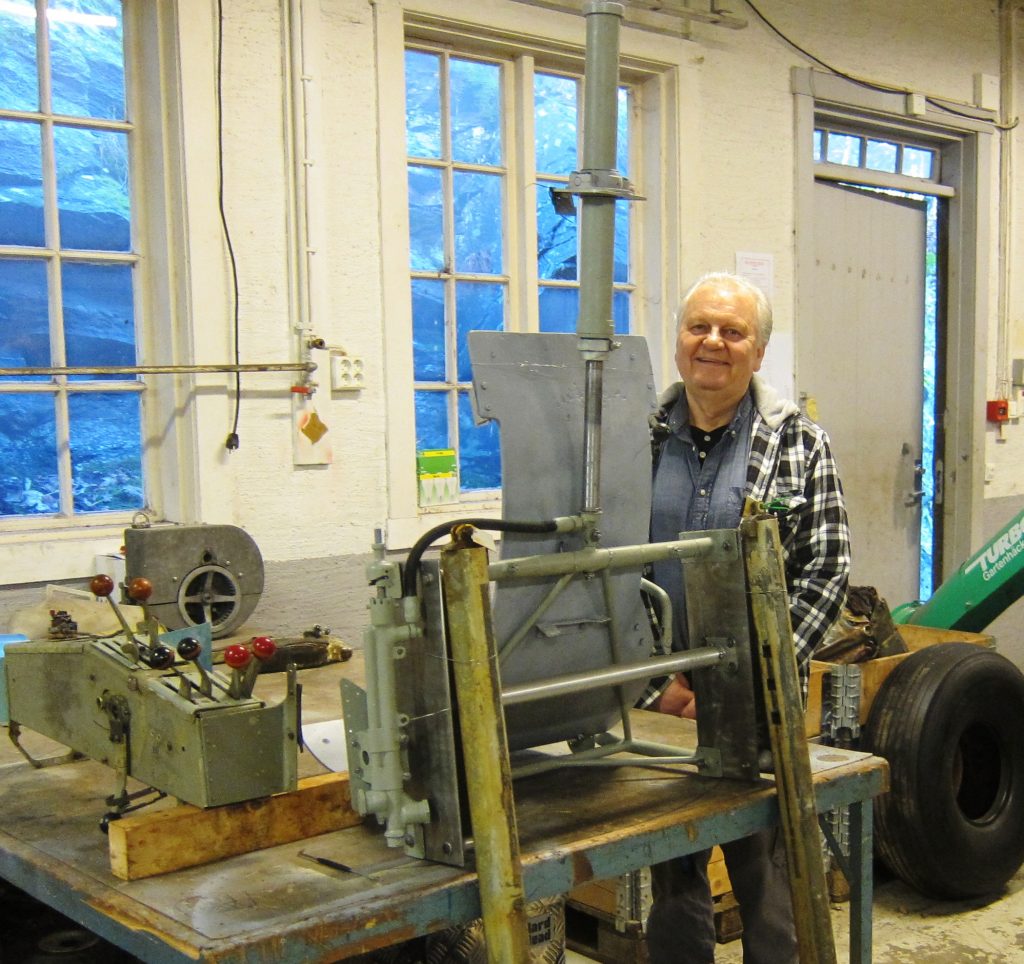

Så er vi heldige og blir kontaktet av Marc Bressan som er bosatt i Sveits. Marc Bressan har en meget solid kunnskap om og erfaring med tyske fly instrumenter. Han hadde selv restaurert og bygd opp en komplett avdriftsmåler. Marc tilbød oss å dele med oss sin omfattende kunnskap og dokumentasjon om He 115 Tribsgërete. Han sendte oss en mengde bilder som viste oss hvordan et komplett system skulle se ut og fungere.

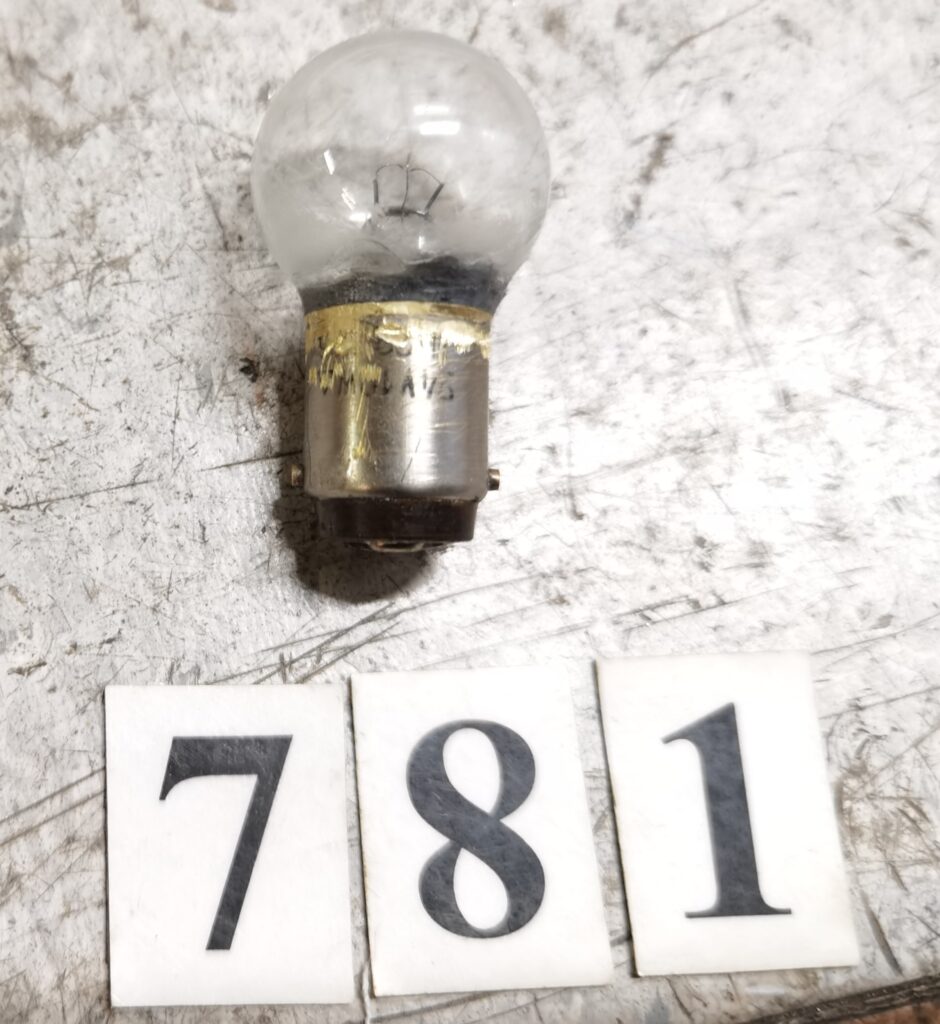

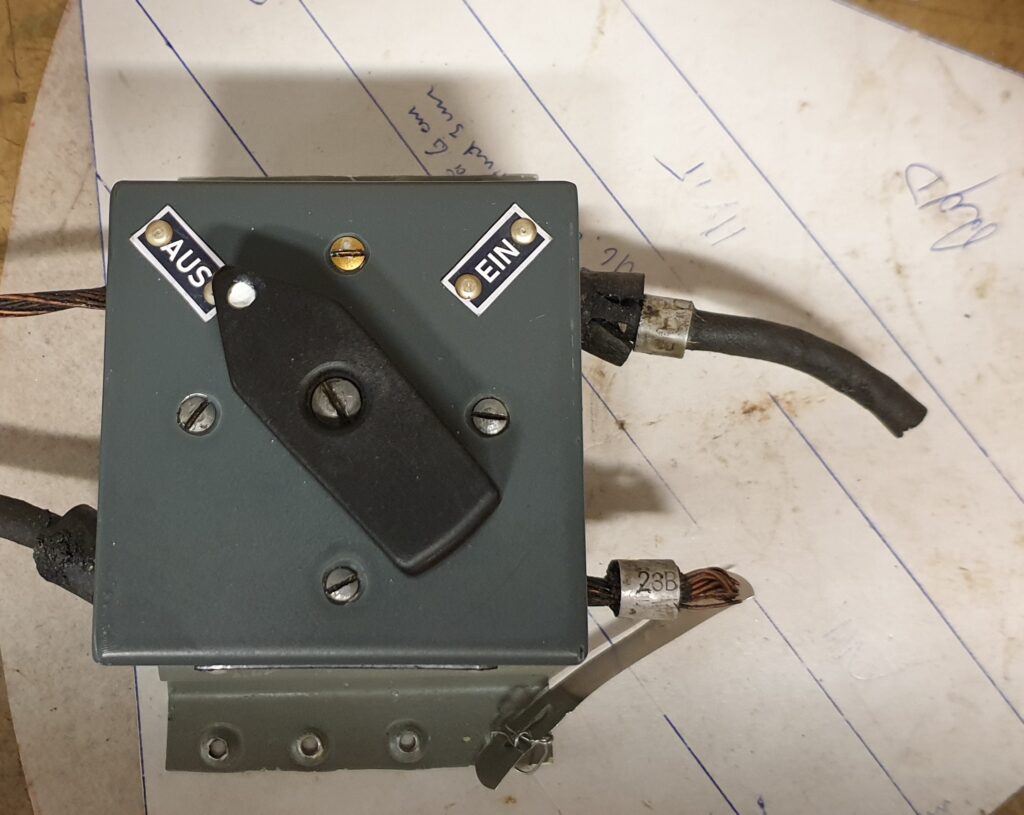

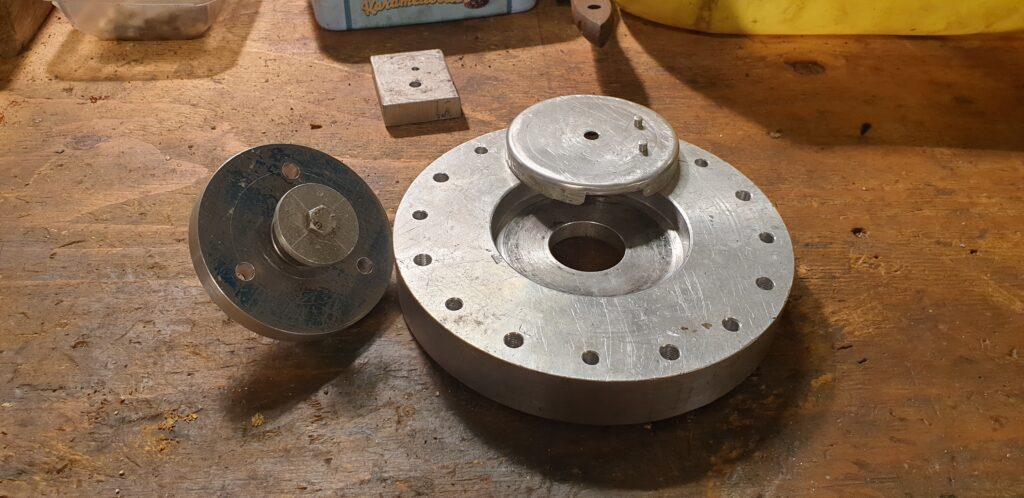

Informasjonen vi fikk fra Marc viste oss at vi manglet veldig mye for selv å ha et komplett system for avdriftsmåling. Marc tilbød seg nå å ferdigstille og donere oss deler som han hadde til overs fra restaurering av sitt eget Tribsgërete. Med disse delene var vi nå i besittelse av et komplett system for avdriftsmåling. Avdriftsmåleren som vi fant i flyet i 2012 var bare midlertidig konservert og ikke åpnet opp for innvendig rengjøring og konservering. Marc åpnet denne for oss og gjorde en grundig innvendig konservering av måleren for. Dette anlegget for måling av avdrift, vil når det er ferdig montert i flyet vise disse godt igjen fremme i Kanzel. Vi er skylder Marc Bressan en veldig stor takk for den hjelpen har gitt prosjektet.

Dette utstyret, sammen med alt annet vi har funnet ombord, viser at det ble trengtes en meget godt utdannet besetning for at de skulle kunne betjene og dra nytte av alle flyets systemer.

De følgende bildene har vi i hovedsak fått i fra Marc Bressan: