Arbeidet med Heinkel He 115 prosjektet har siden i januar vært styrt av at Forsvarsmuseet er inne i en prosess hvor de skal vurdere fremtidig eierskap for utstyr som er lånt ut på deponiavtaler. Vi har derfor fortsatt noen midlertidig noen restriksjoner på arbeidet med Heinkel He 115 prosjektet.

I tillegg har lufttemperaturene i vinteren vært uvanlig lave her på sør Vestlandet

. Kulden har gjort lite attraktivt å videreføre det arbeide som vi i har holdt på med ute i Heinkel hallen

therapy and the subsequent resumption of sexual activity issexual problems. viagra vs cialis.

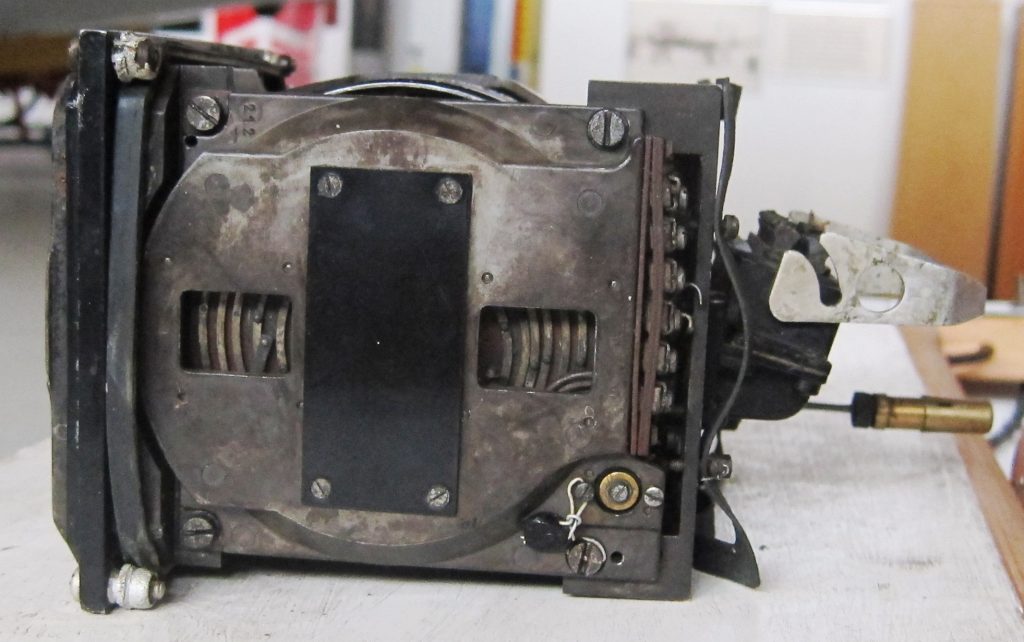

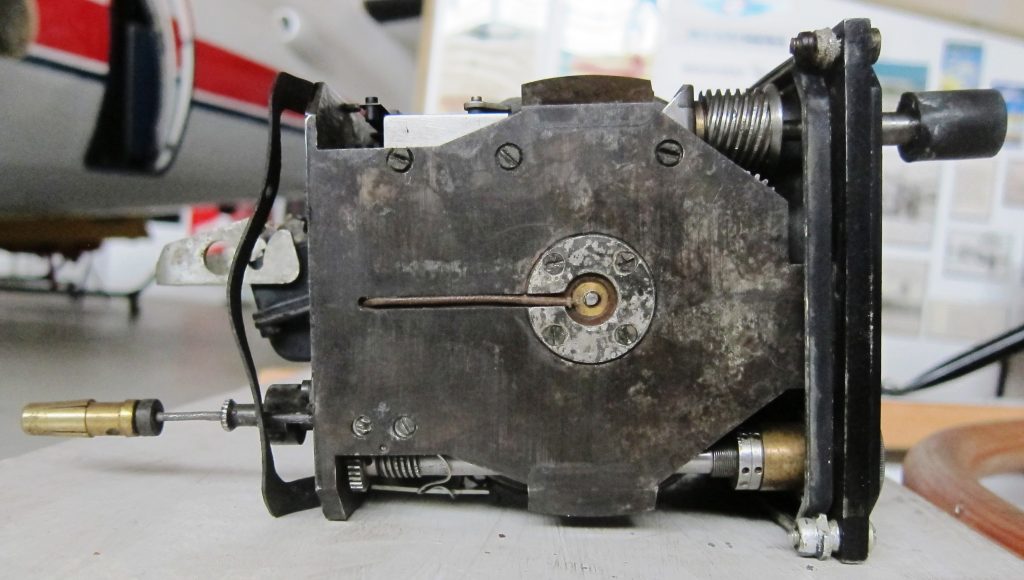

. Dette er arbeid som består i å katalogisere de smådelene som enda ikke er ferdig registrert

. Dette er arbeid som vil bli videreført når sommerens aktivitetene begynner å ebbe ut.

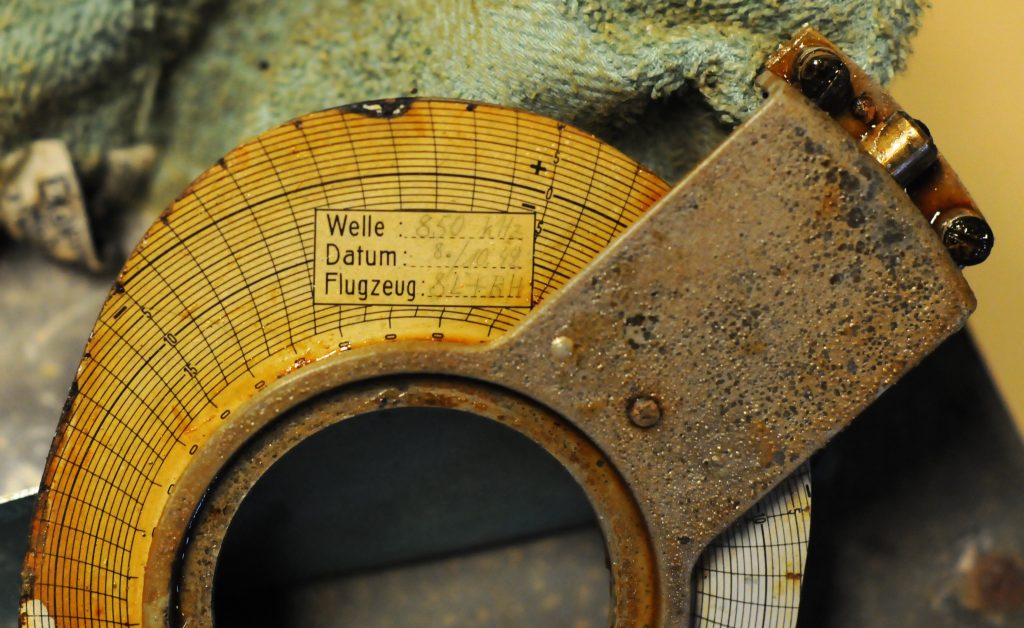

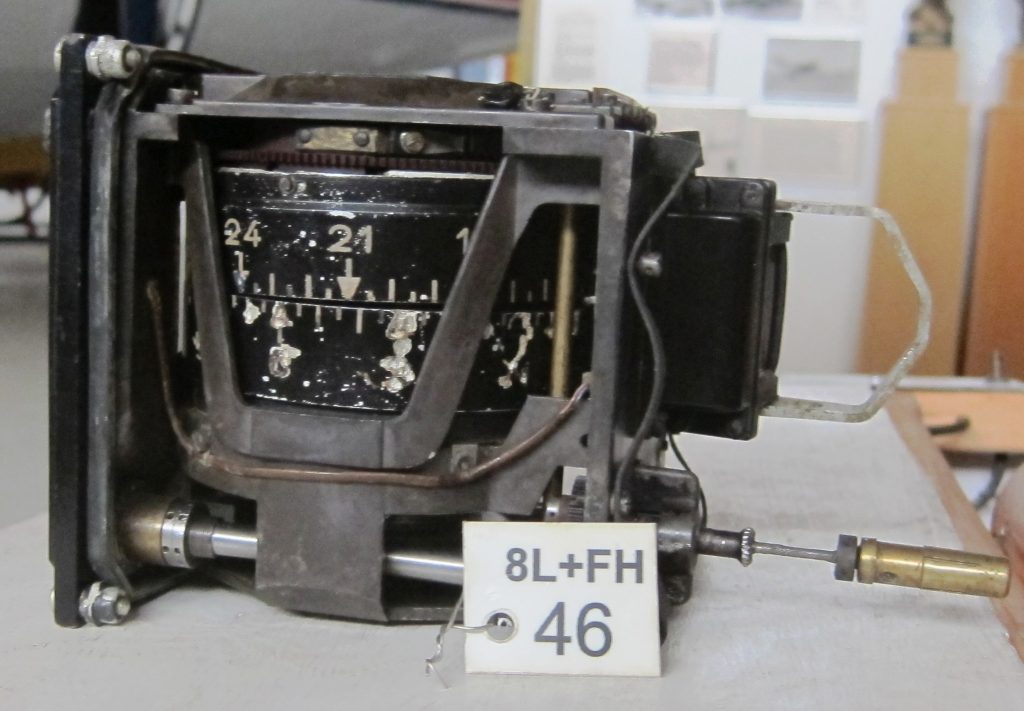

Heinkel 115 prosjektet er tildelt et eget rom i museets utstilling

. Her arbeider vi for tiden med å lage en utstilling rundt flyet og utvalgte mindre deler dette.