Det nærmer seg sommer sol og ferie, og aktiviteten i Heinkel 115 prosjektet vil bli lav frem til utpå sensommeren. Vi har i løpet av de siste månedene i hovedsak arbeidet med å forberede den store jobben med å spyle alle sammenføyninger og plateskjøter i senterseksjon og vingetipper rene for salt. Arbeidet med forberedelsene har vært både tidkrevende og kjedelig, men likevel et helt nødvendig arbeid, som dessverre viser veldig lite igjen i den store sammenhengen. Det er derfor heller ikke mye å fortelle om eller å vise frem bilder fra

. Trøsten er at vi nå er klare til å starte med vannspylingen, når vi igjen starter opp arbeidet etter sommerferien.

Vi arbeidet også videre med å få på plass en løsning for å tørke luften ute i Heinkel hallen. Det er i skrivende stund enda ikke helt avklart om vi skal satse på å bruke et eldre aggregat som vi har fått, eller om vi heller skal kjøpe inn et nytt og moderne aggregat.

Vår gode venn Georg som har begynt å arbeide sammen med oss, og gjør for tiden en glimrende jobb med å restaurere flygerens sete med sete tilhørende oppheng.

Arbeidet med å ferdigstille trottle boksen, har blitt nedprioritert som en følge av arbeidet med å klargjøre for spyling av sammenføyninger og plateskjøter, ute i hallen. Litt arbeid er det likevel blitt gjort på boksen i løpet av de siste ukene

. Denne var når vi begynte på den, full innvendig av mudder fra fjordbunnen, og lakken var sterkt forurenset av prosessen som følger av å ligge 70 år i sjøvann. Den ble i løpet av vinteren blitt helt demontert og mekanisk renset, før vi begynte på arbeidet med å rense alle komponentene. De fleste av disse ble så først vasket i en Biltema ultralydvasker med Biltema kaldavfetting som vaskemiddel. Deretter ble de lagt noen timer i en 10 % Oksalsyre løsning, før de deretter ble nøytralisert i et vannbad innblandet med 2 % Blue Gold alkalisk såpe. Så var det tid for å vurdere hva vi så skulle gjøre for å beskytte originallakken mot fremtidig slitasje, før vi igjen begynte å montere de sammen igjen alle de delene som en slik boks består av. Valget sto mellom å bruke Lanolin, lakkere med en celluloselakk eller å bruke Dinitrol Corroheat 4010. Valget falt til slutt på Corroheat 4010 fordi dette ga en overflate som ikke samler støv, og som ikke er klebrig å ta i. Den kan og, om det skulle bli nødvendig, fjernes igjen fra overflatene på et senere tidspunkt. Hensynet til at overflaten ikke skulle klebe ble avgjørende for valget av behandling. Dette siden trottle kassen første omgang er tenkt stilt ut som en komponent som besøkende kan komme til å berøre. Brytere for magneter, stigning kontroll og startere er enda ikke klare for overflate behandling, og vi har heller ikke enda bestemt hvordan disse skal behandles. Gasshendler med lås, samt hendler for bensin og utløsere for brannslukking er montert tilbake i kassen, og fungerer nå nesten som da flyet var nytt.

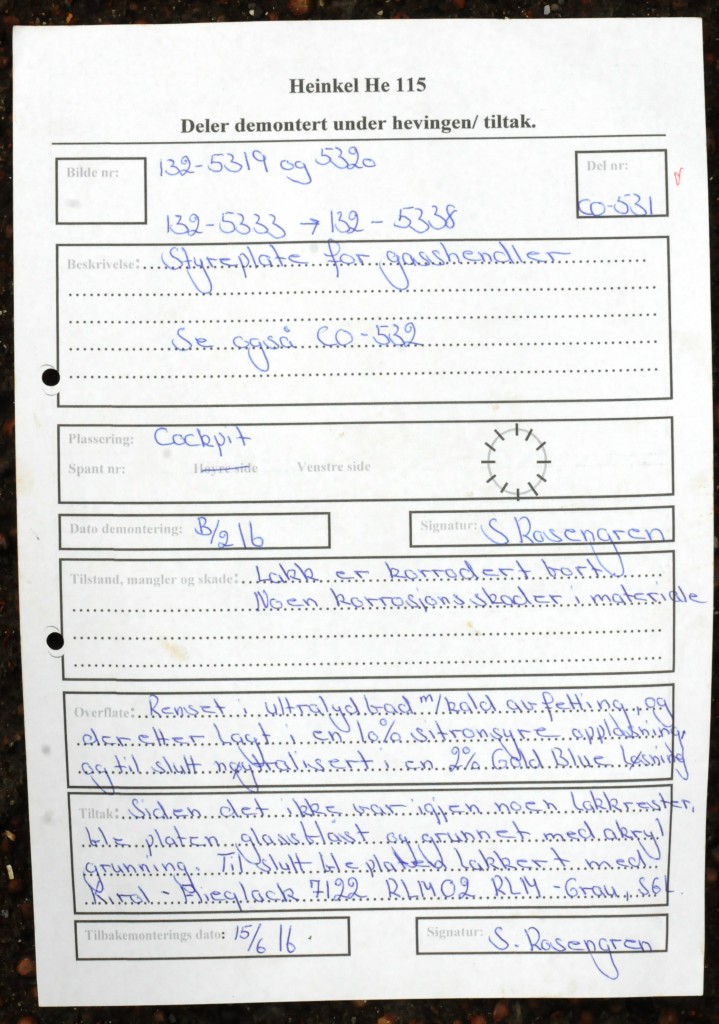

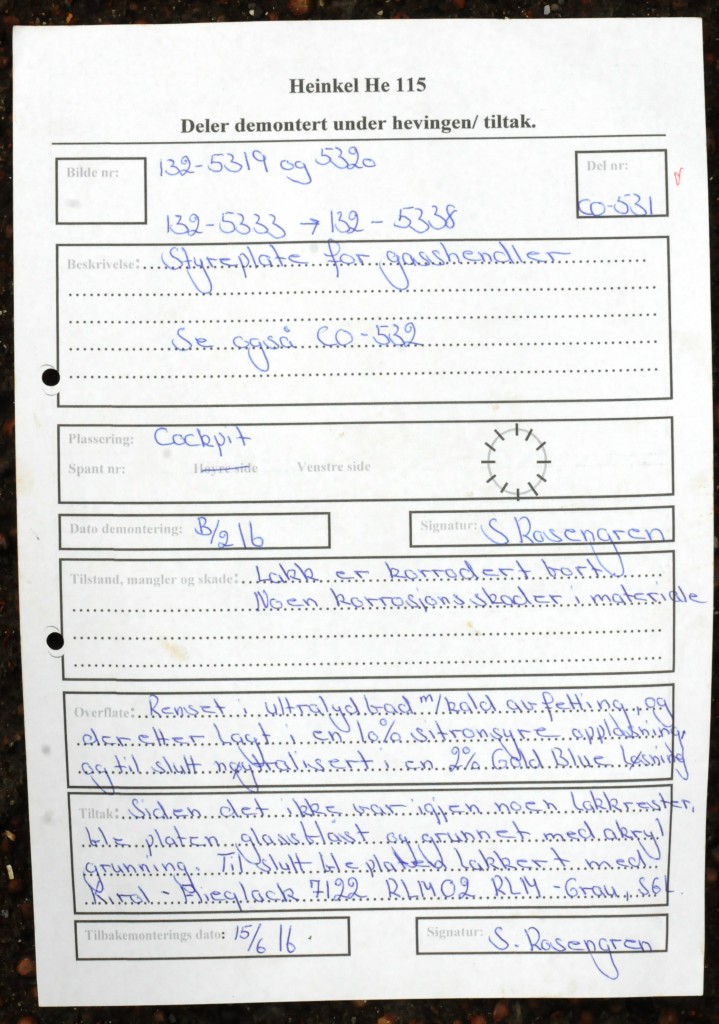

Det er en liten milepæl når vi nå har begynt å montere tilbake noen enkeltkomponenter. Alle komponenter som er blitt demontert, er blitt merket med et unikt nummer. Dette er så kartotekført på et registreringsskjema, hvor informasjon om delen, hvor denne var lokalisert, hvilke bilder som er tatt av delen m.m. er blitt som notert. Informasjonen er så igjen blitt registrert digitalt. Det er en god opplevelse når vi nå for første gang kunne fylle inn slutt informasjon om hva som er blitt gjort med en del, før den ble tilbake montert, og så kvittere på at jobben var ferdig.

Vi ønsker alle som leser denne posten en riktig god og lang sommer.

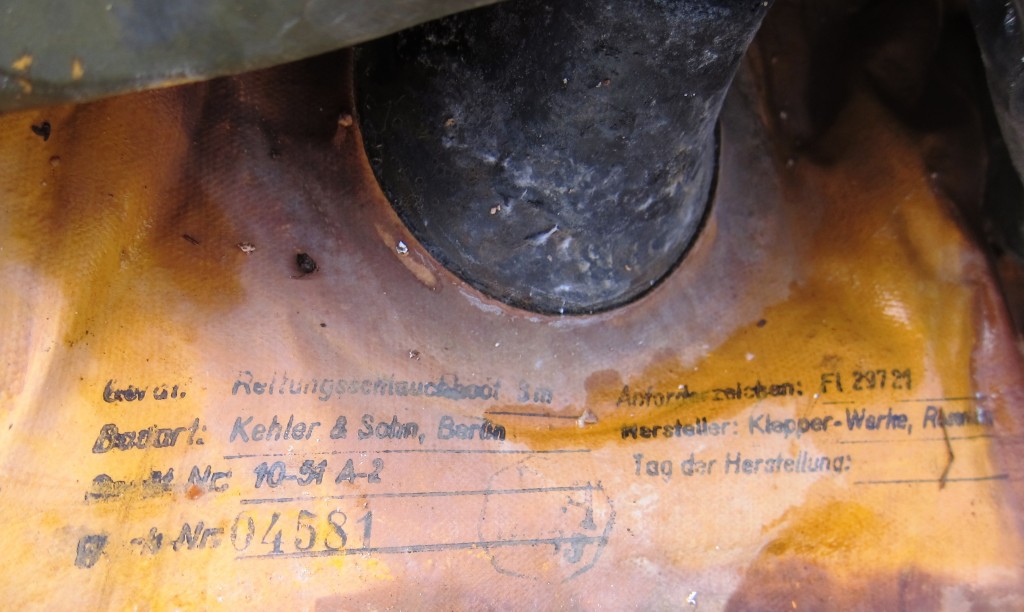

Trottle boks før demontering og rensing

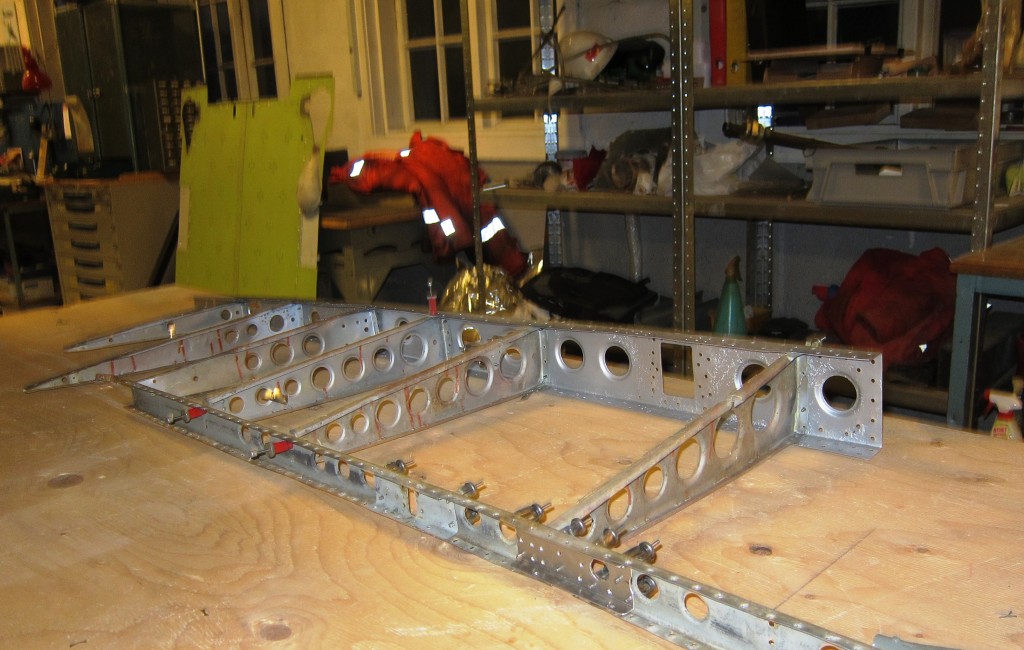

Trotle boks etter rensing og at gass, bensing og brannhendler igjen er montert tilbake.

Her er enda noen detaljer montert

En milepæl når vi nå kan begynne å supplere registreringsskjemaer med slutt informasjonen

Georg har en stødig hånd med å restaurere mekanisk innviklede deler, her en mekanisme for justering av flygerens sete