Høsten 2024 har vært en periode hvor det har skjedd mye. Vi har nå flere samtidig pågående aktiviteter med god fremdrift.

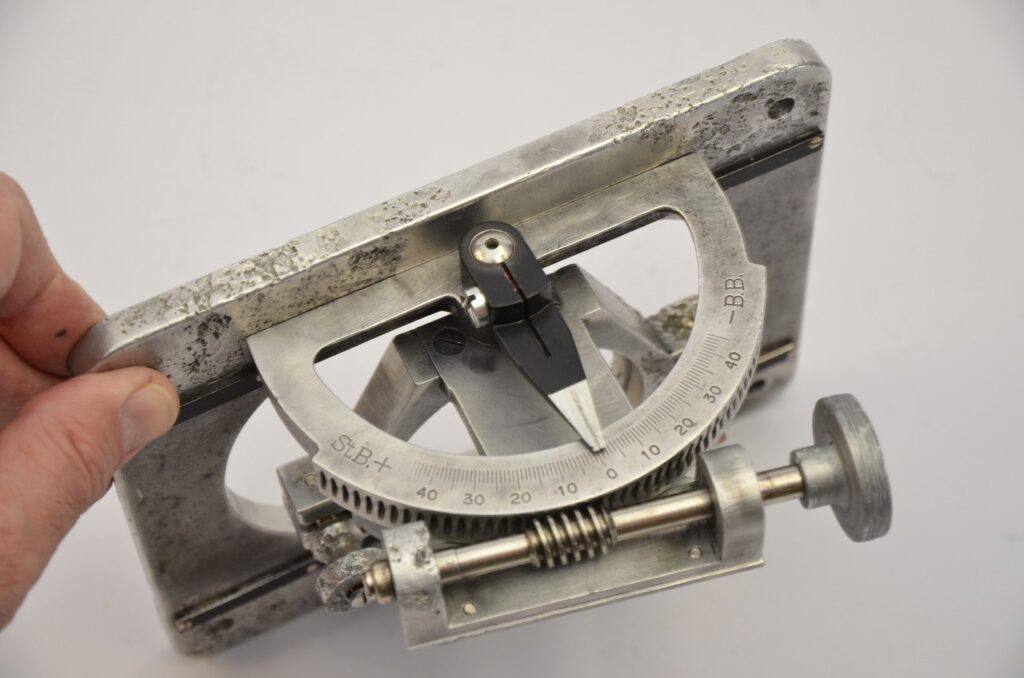

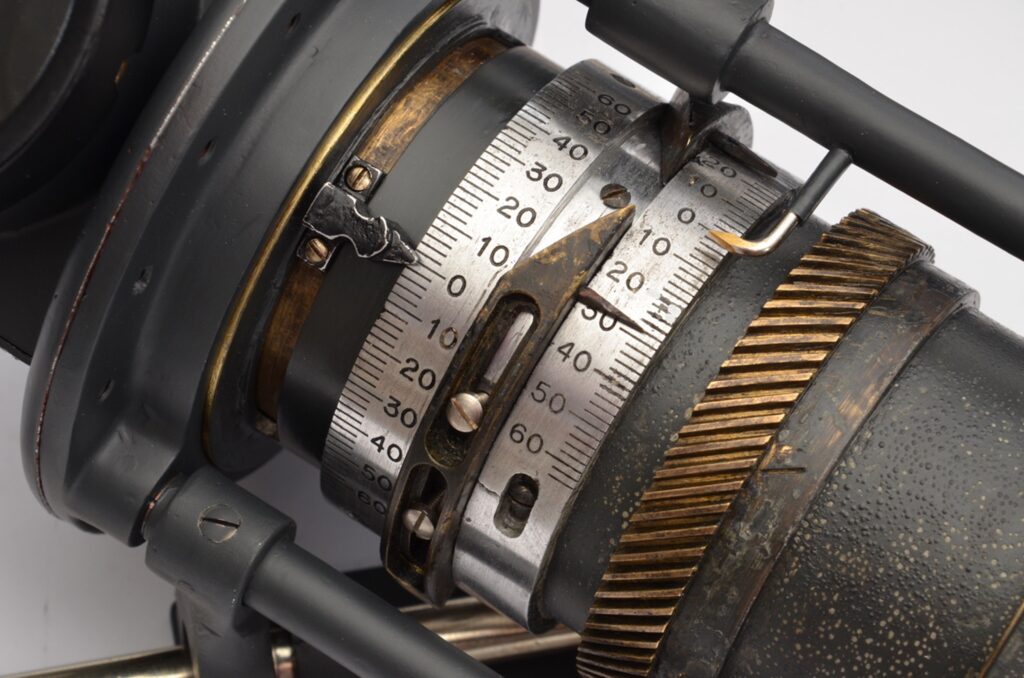

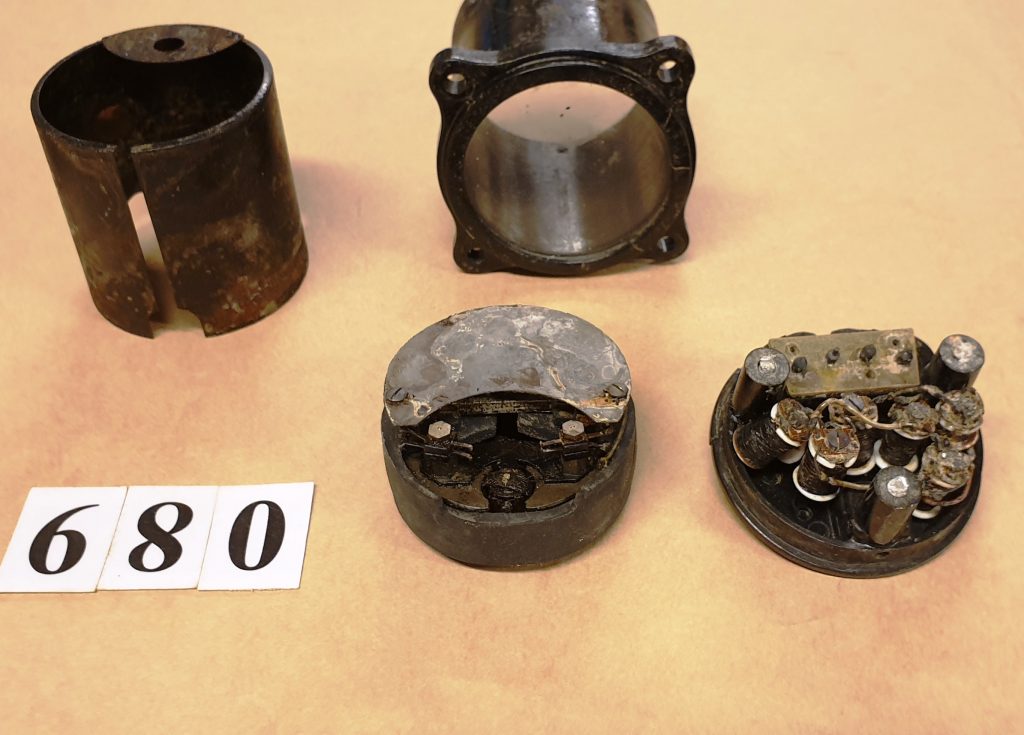

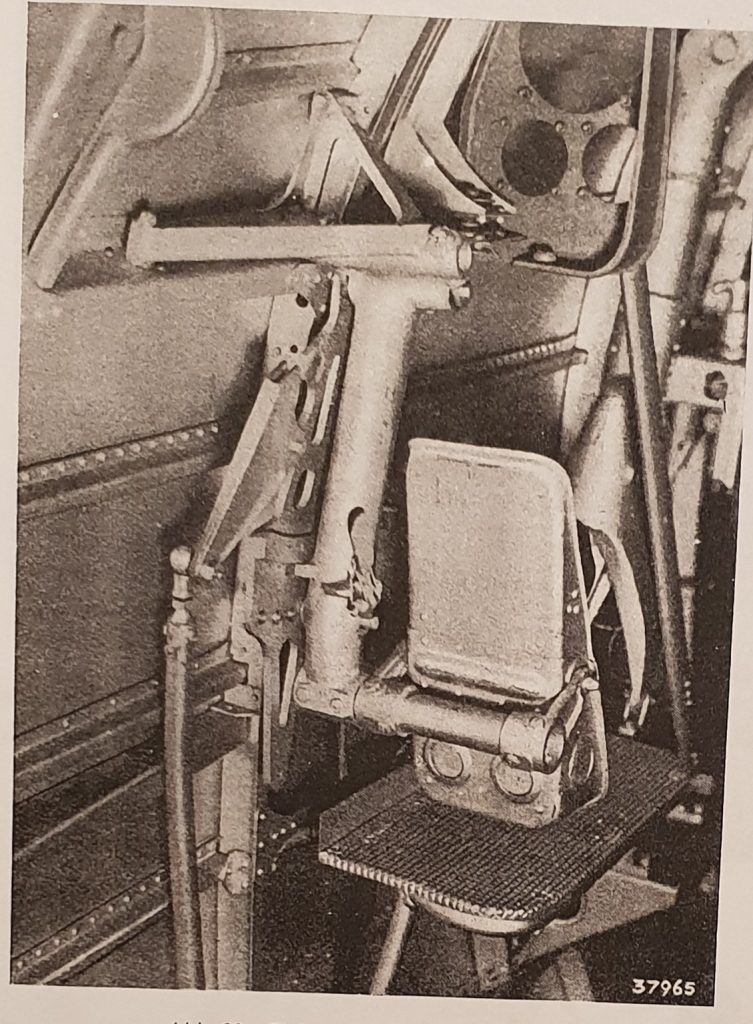

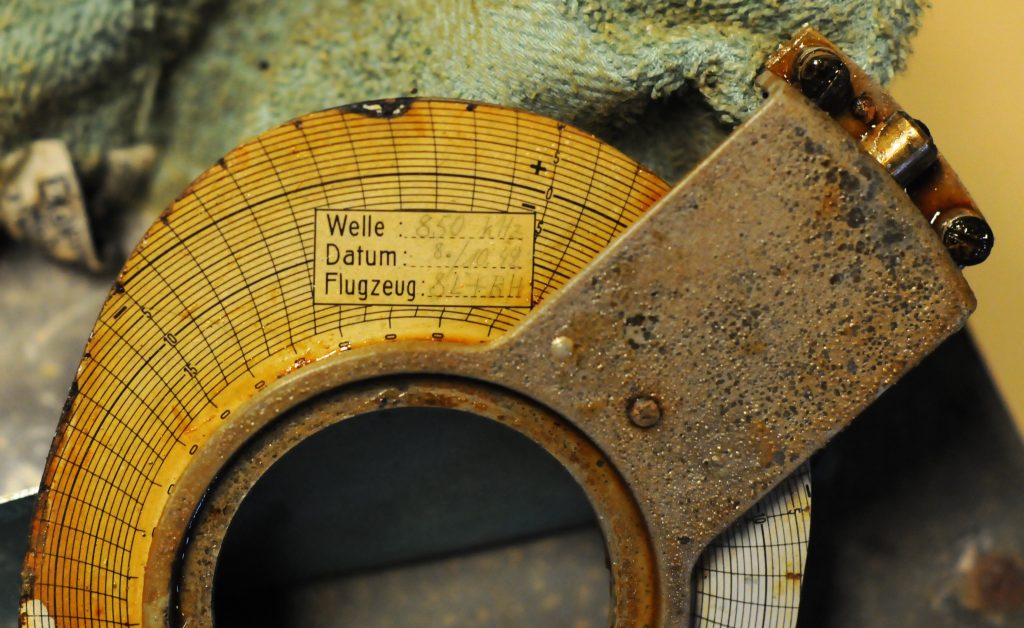

Det har blitt jobbet godt med å tilbake montere deler som i 2014 ble tatt ut ifra nese- og cockpit seksjonene. Mye arbeid gjenstår, men vi nærmer oss det punkt hvor det vi har av originalt utstyr er på plass i de to seksjonene. Det gjenstår å gjenoppbygge flyets styre kolonne, samt systemet for høyderors trim. Heldigvis har vi deler igjen av disse to komponentene som vi kan brukes i dette arbeidet. Pilotens sete er ferdig gjenoppbygd ut av gjenværende originale deler, og står nå klar for tilbake montering i cockpit. Det arbeides nå med å gjenoppbygge det som var av hydraulikk anlegg i nese- og cockpit. Dette gjøres med å kombinere bruk av det vi har av originale rør og koplinger med å lage nytt det som mangler.

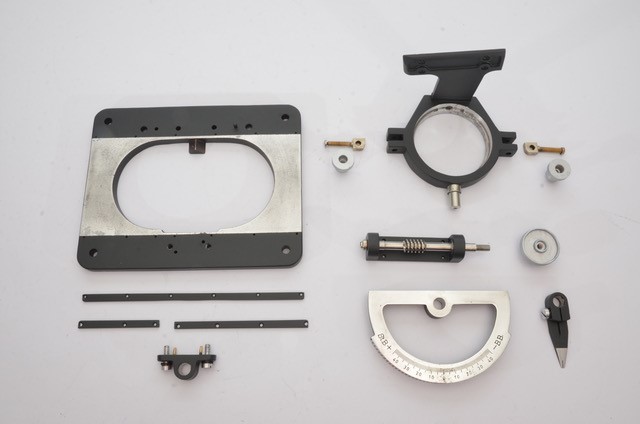

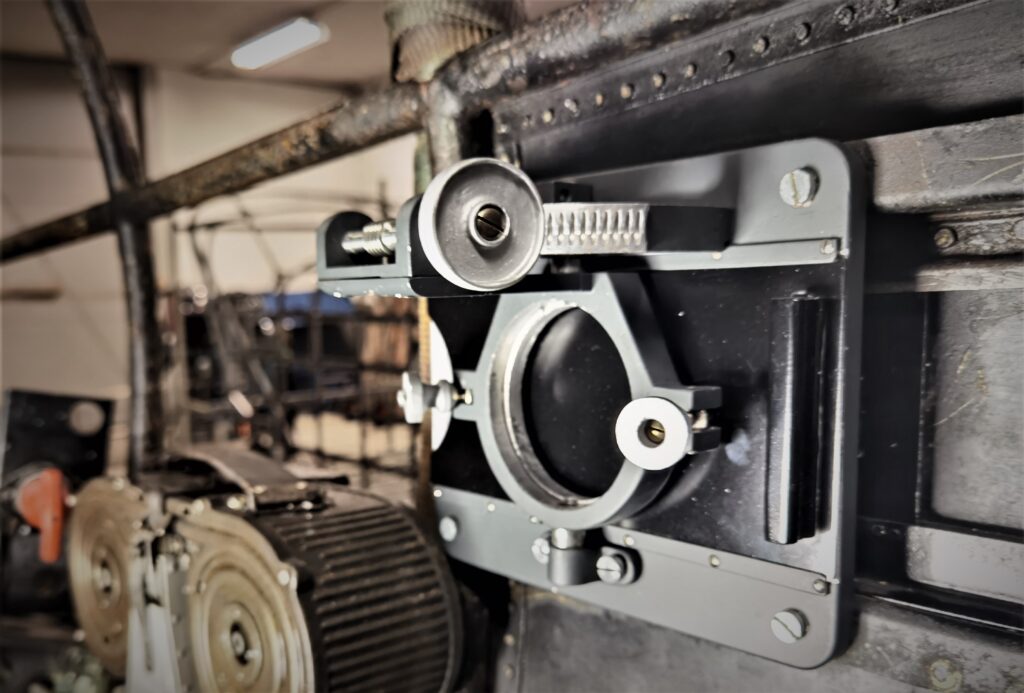

Vi er nå endelig kommet i gang med arbeidet med å utbedre korrosjons skadene på senterseksjonens motor, flottør- og vinge fester. I forkant av dette arbeidet har vi brukt tid på å bygge en `seng` hvor på seksjonen skal ligge mens utbedringene pågår. Vi har bygget jigger for å sikre at vingefestene blir montert tilbake i rett posisjon. Disse er bygget slik at et av de fire vinge festene kan blir løsnet, mens de tre andre holder konstruksjonen stabilt i posisjon. Det er bygget en jigg til hver til sin ende av senterseksjonen. Store krav til jiggenes nøyaktighet gjorde at det har kostet oss mye tid og arbeid å bygge dem.

Vi har nå boret løs og tatt ut det første av åtte vinge fester.

Vingefestet som er blitt demontert ble lagt i et elektrolysebad i to døgn. Resultatet av denne behandlingen er svært god.

Underveis i arbeidet har vi gjort oss flere erfaringer. Vi har funnet korrosjon der hvor vi forventet at det skulle være korrosjon. Samtidig har vi åpnet mellom tett sammen naglete plater hvor sammenføyningene er helt uskadde. Vi kan enda ikke si sikkert hva som forklarer fraværet av salt og korrosjon i disse sammenføyningene. Mest trolig er forklaringen tre delt.

- Det er brukt aluminium som er sjøvanns bestandig.

- Overflate behandlingen har hatt en høy kvalitet.

- Platene har blitt påført en `flytende` tetningsmasse før de ble naglet i sammen

Dette siste kan har gitt en tett sammenføyning som har klart å motstå 70 års eksponering mot sjøvann. Forklaringen kan også være annerledes og tilstanden i andre sammenføyninger trenger ikke å være like god.

Vi håper at vi skal kunne konservere store deler av senterseksjonen uten å måtte åpne et stort antall plate sammenføyninger. Derfor er det startet en utredning i regi av Museums Spesialistene. Dette er et kompetansesenter som leverer råd og tjenester til en rekke museer i regionen. Studien vil ha det som mål å finne en best mulig metode å forebygge at det skal kunne utvikle seg korrosjon i sammenføyninger. Senterseksjonen består av et høyt antall sammen naglede plate sammenføyninger. Disse har i 70 år ligget neddykket i saltvann. En må forutsette at kapillar krefter har fått salt til å migrere inn i disse. Store deler av senterseksjonen har få synlige spor av korrosjon. Lykkes vi i vårt mål, kan dette, sett i verdens målestokk, være en spesiell måte å ta vare på originaliteten i et sjøvrak.

Arbeidet med senterseksjonen utføres i det som opprinnelig var bassenget hvor flyet de to første årene ble lagret flyet neddykket i ferskvann. Nå som det er vinter fungerer betong konstruksjonen som en kulde akkumulator. Dette sammen med en luft avfuktet atmosfære gir et krevende arbeidsmiljø.