Høsten og vinteren 2025 har vært en periode hvor det har skjedd mye i Heinkel He 115 prosjektet. Det har blitt arbeidet godt både med å bygge en ny hood og med å videreføre ferdigstillelsen av cockpit og Kanzel. Også på senterseksjonen er det blitt gjort gode fremskritt.

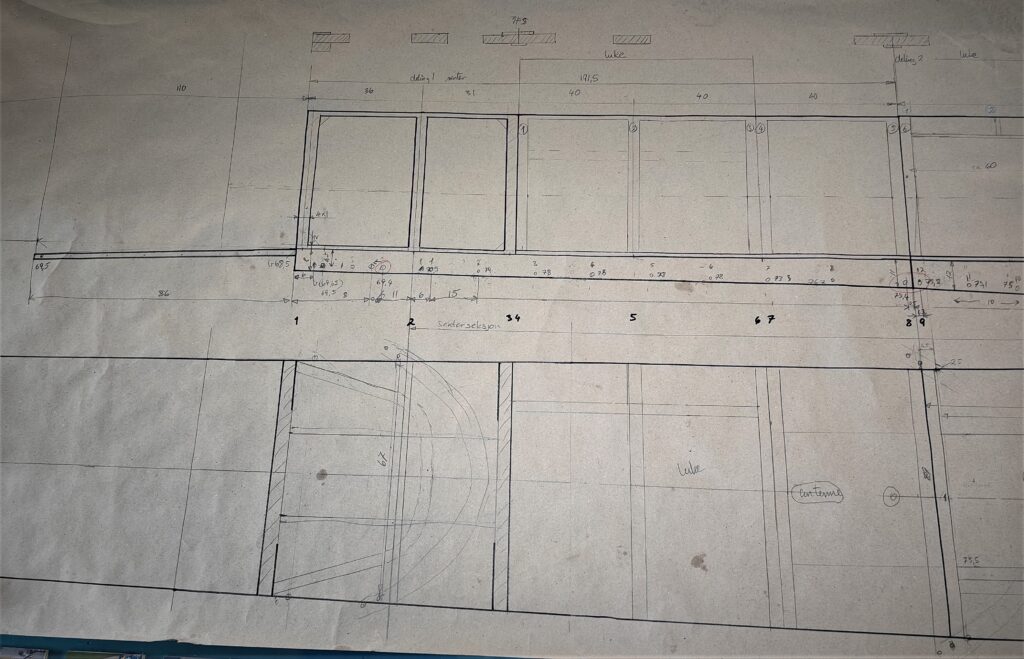

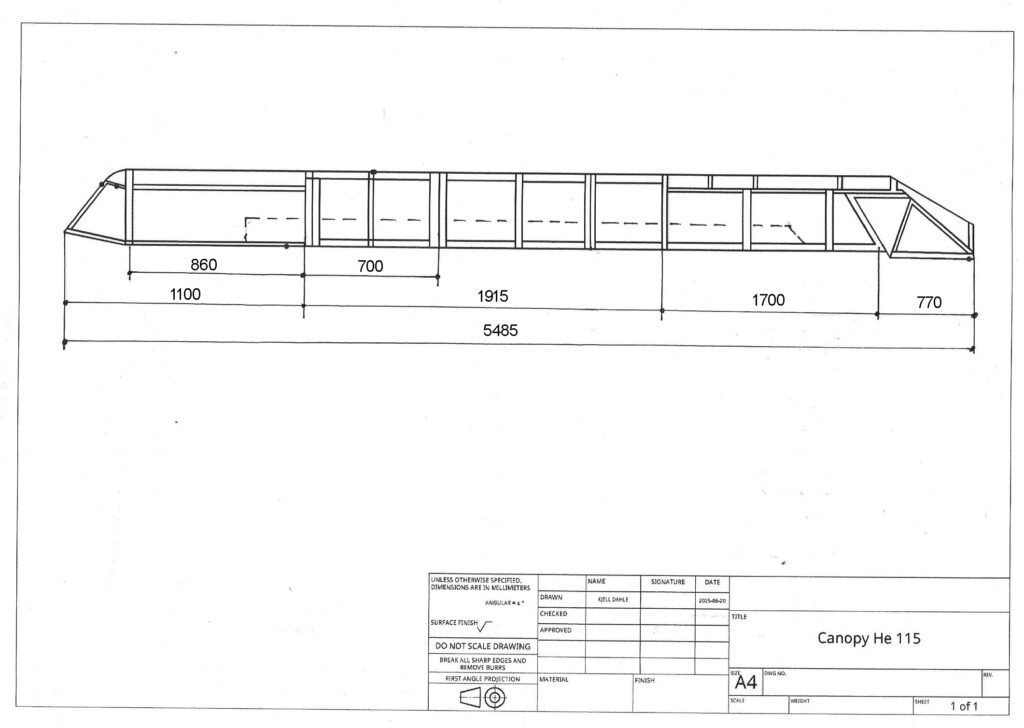

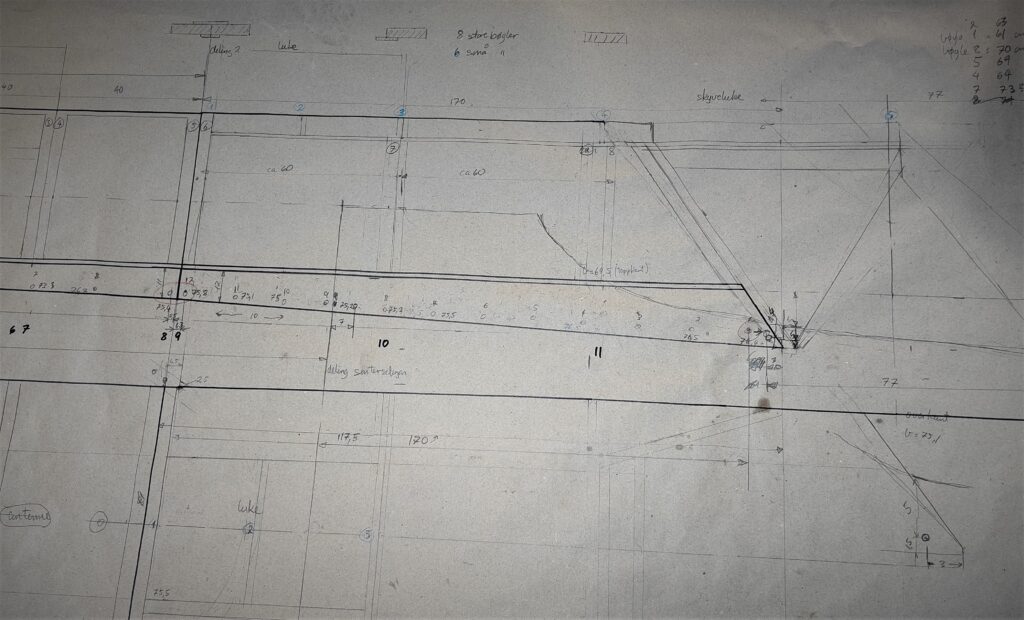

Trearbeidet knyttet til det å bygge en ny hood er kommet så langt som det nå foreløpig er mulig å komme. Hood`en er en 5 meter lang og kompleks tre konstruksjonen. Denne danner fortsettelsen bakover fra canopy over piloten og bak til bakkant av telegrafistens cockpit. Konstruksjonen er utstyrt med flere luker som enten åpnes sideveis, eller som skyves fremover når dekslet over telegrafist cockpiten åpnes. Dessverre var lite igjen av den originale trekonstruksjon. Det som fulgte flyet opp, da dette ble berget, er blitt intrigert i denne nye konstruksjonen. Vi venter nå på plexiglass og det som trenges av aluminiums lister for å kunne ferdigstille hood og luken over telegrafisten. Det er også blitt laget et utkast til flygerens canopy. Til denne har vi flere deler som vil bli gjenbrukt i den nye konstruksjonen.

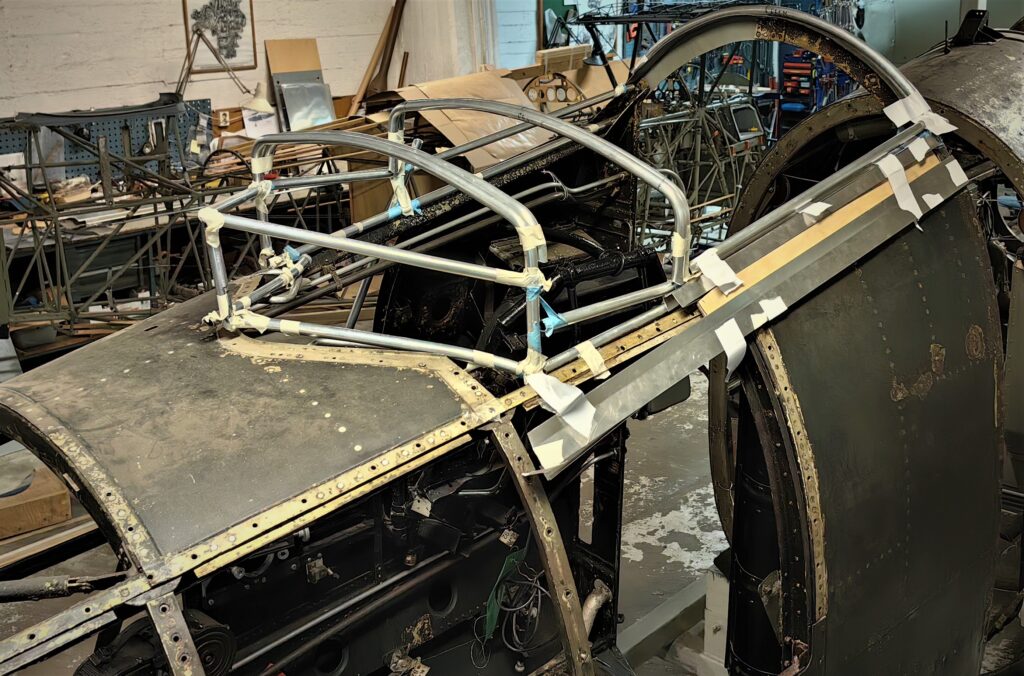

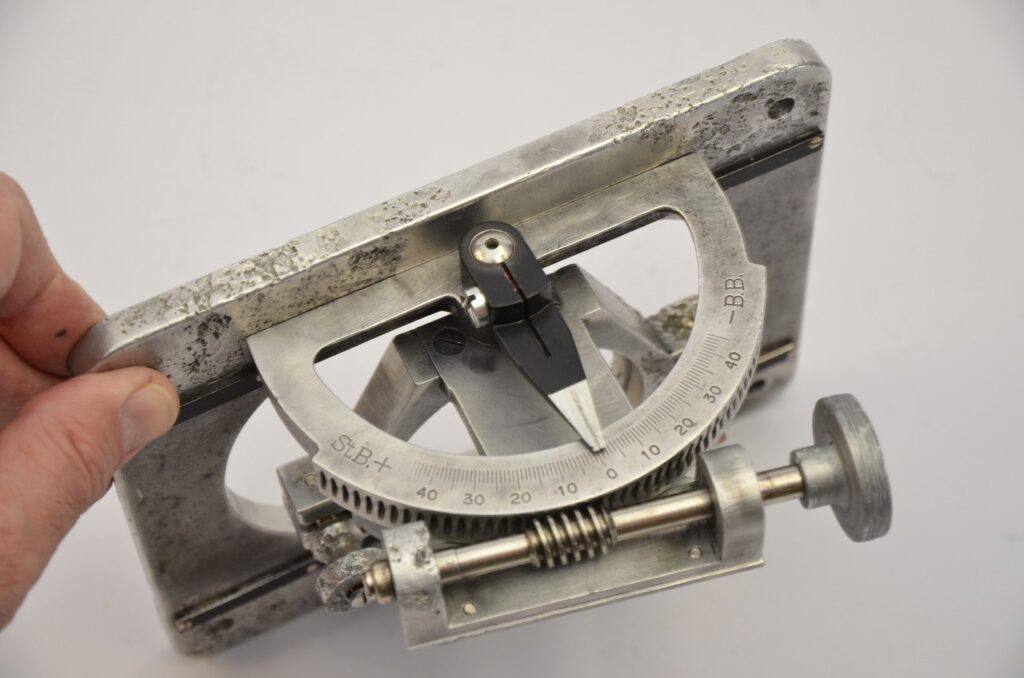

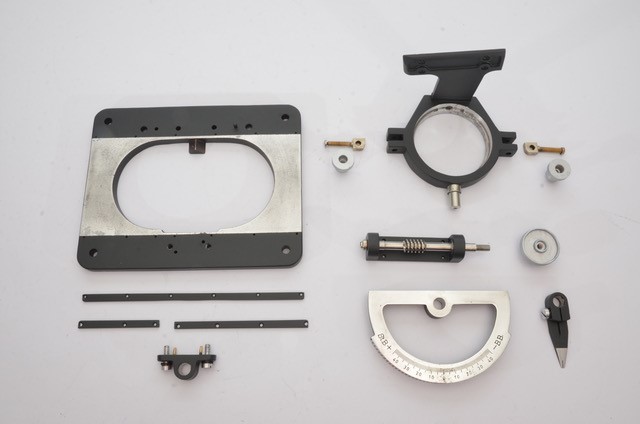

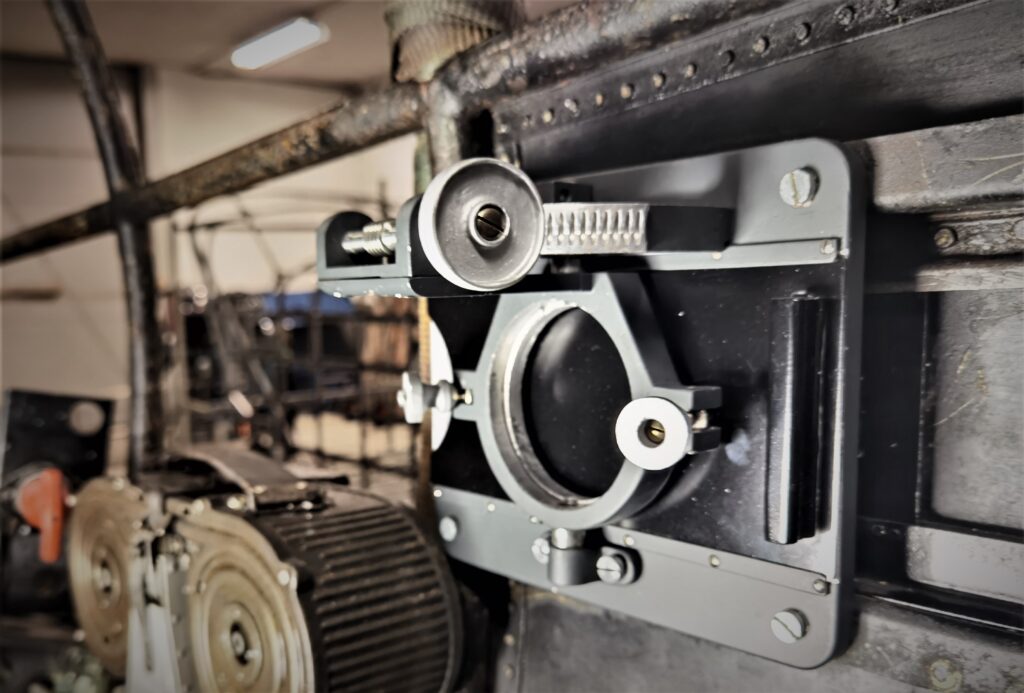

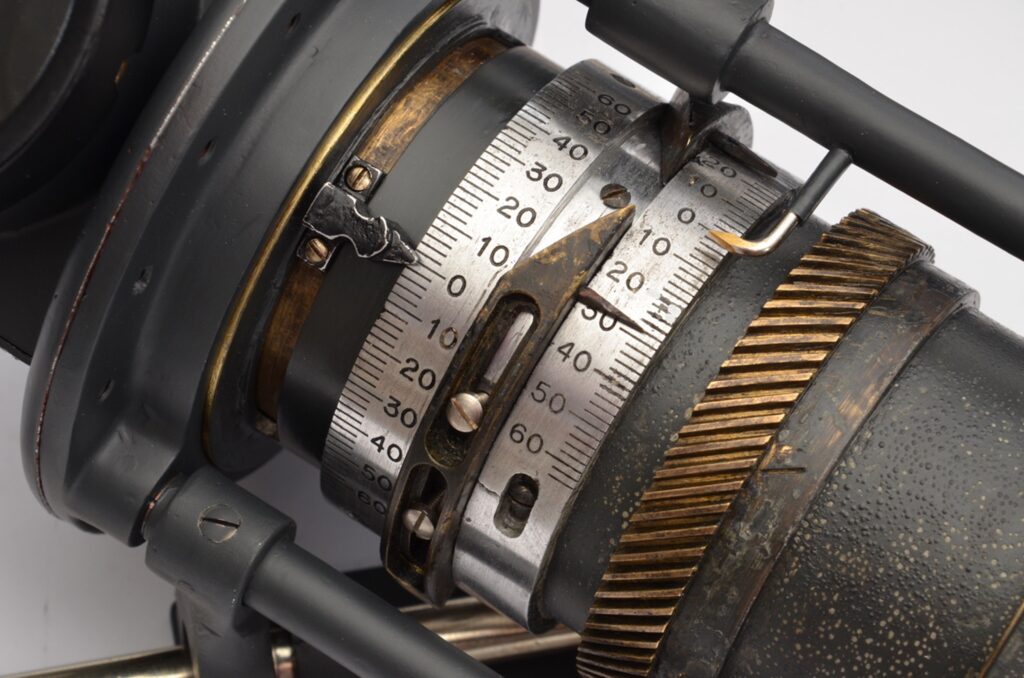

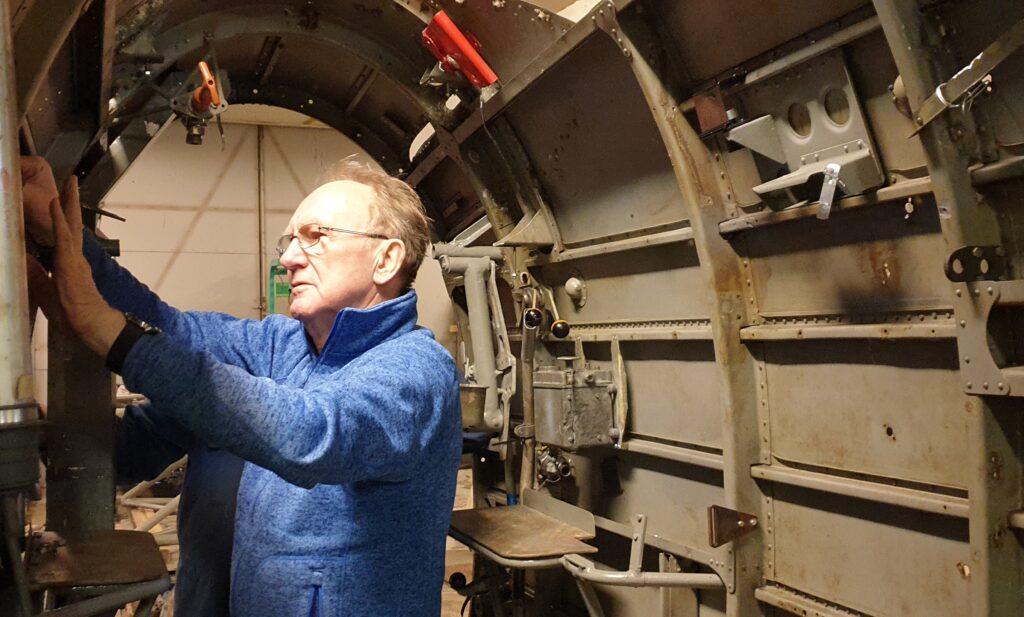

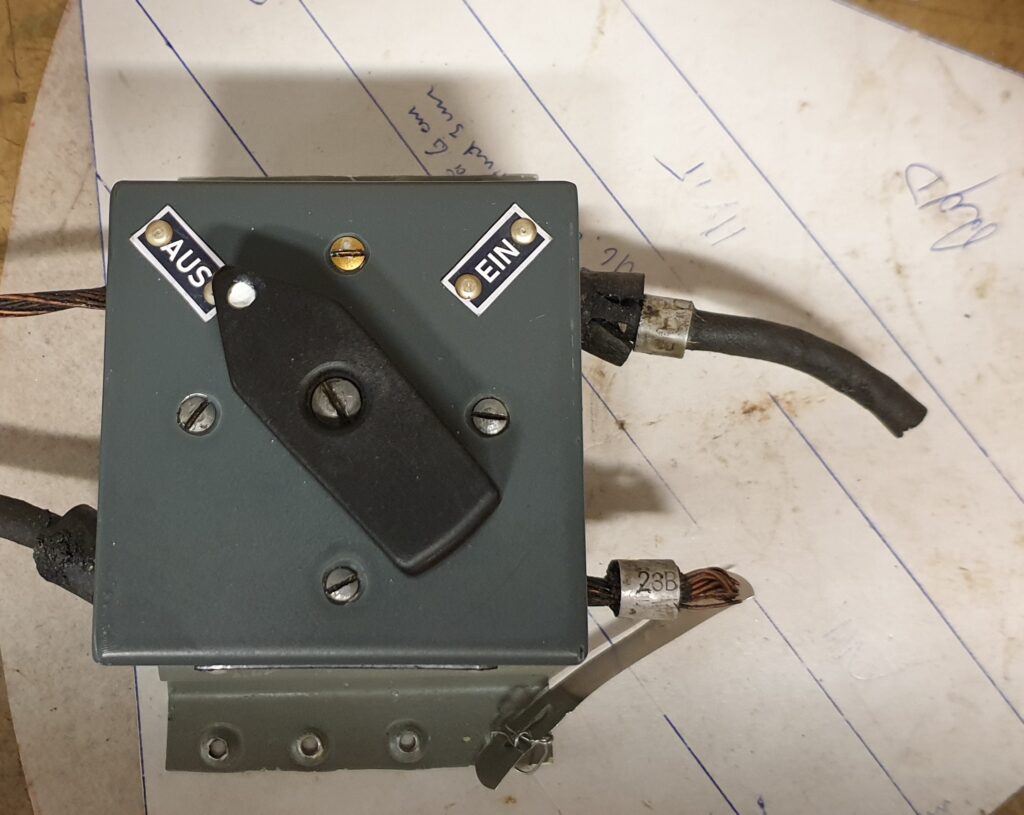

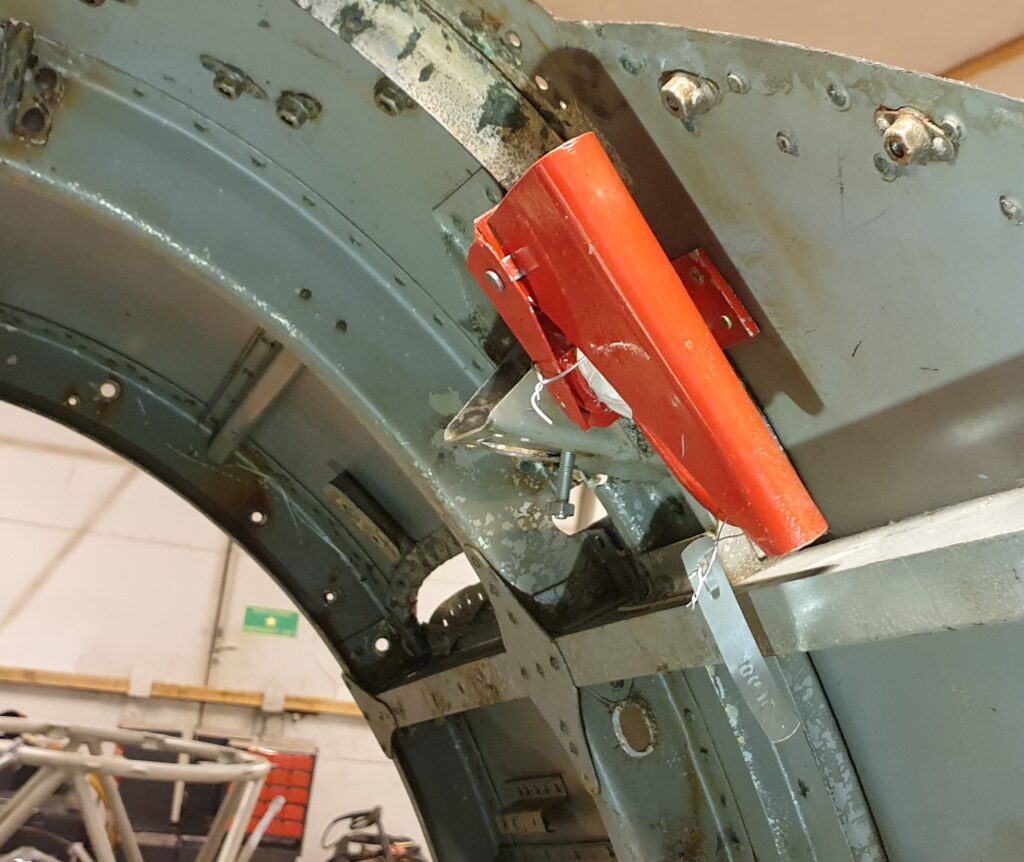

På Kanzelen har en fortsatt på arbeidet med å lage nye luker. Det er bestemt at den store luke / glasskonstruksjonen over navigatørens sitteposisjon skal bygges av aluminiums flattjern. Den første løsning var å bygge denne av rør. Rørene blir nå heller bli brukt som maler foren aluminiums flattjerns konstruksjon. Bilder viser at begge løsningene er blitt brukt da Heinkel fabrikken bygget disse flyene. Åpne / lukke vinduet helt nede og til høyre fremst i Kanzel er gjenoppbygd, og er nå tilbake montert i flyet. Det arbeides nå med å lage ny den store luken fremme på toppen av Kanzel. Av den originale luken er det bare tilbake noen hengsler, låser og en åpne / lukke skinne. Heldigvis har vi alle glassvinduene, med tilhørende klemlister, som tilhører Kanzel. Glass og lister er blitt renset og er i en veldig god stand. Dessverre mangler vi selve Iberiakuppelen. Denne ble igjen nede på bunnen av Hafrsfjorden da flyet ble hevet. MG 15 som sto i kuppelen da flyet havarerte ble berget og er i en svært god stand.

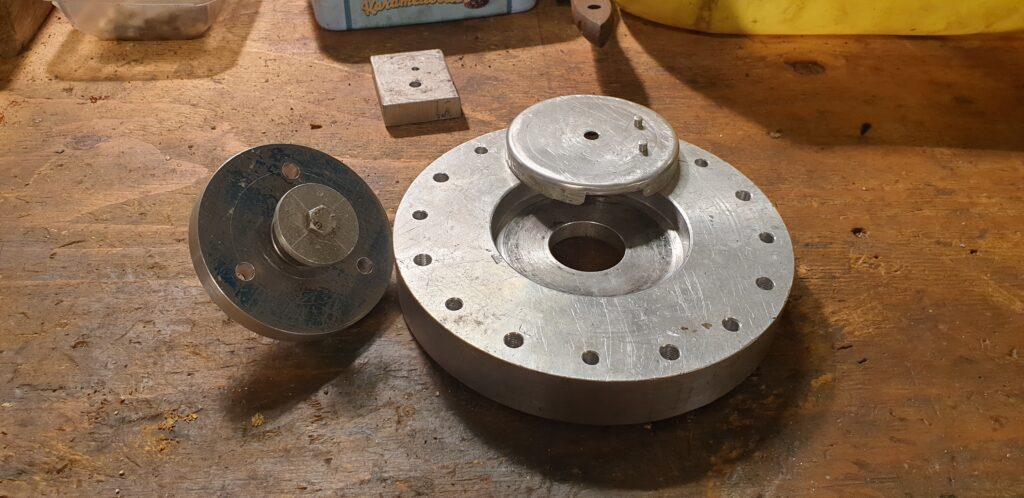

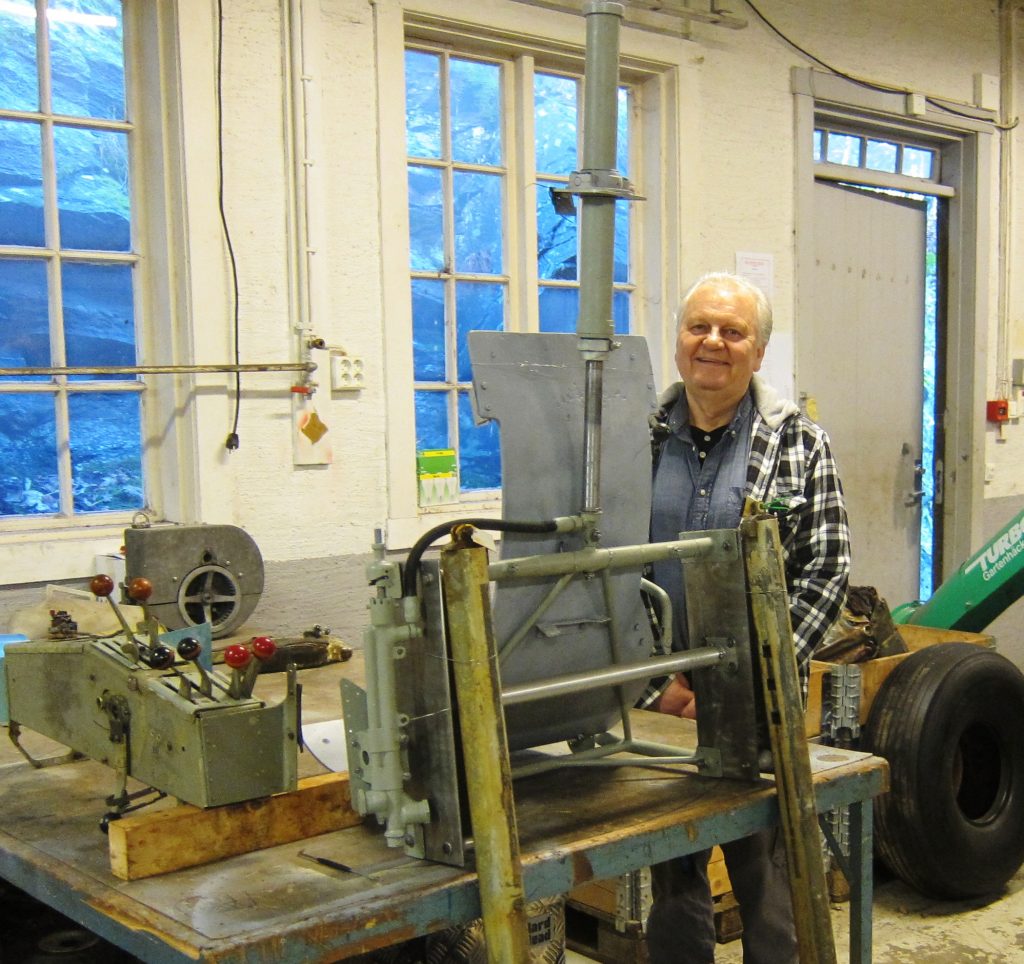

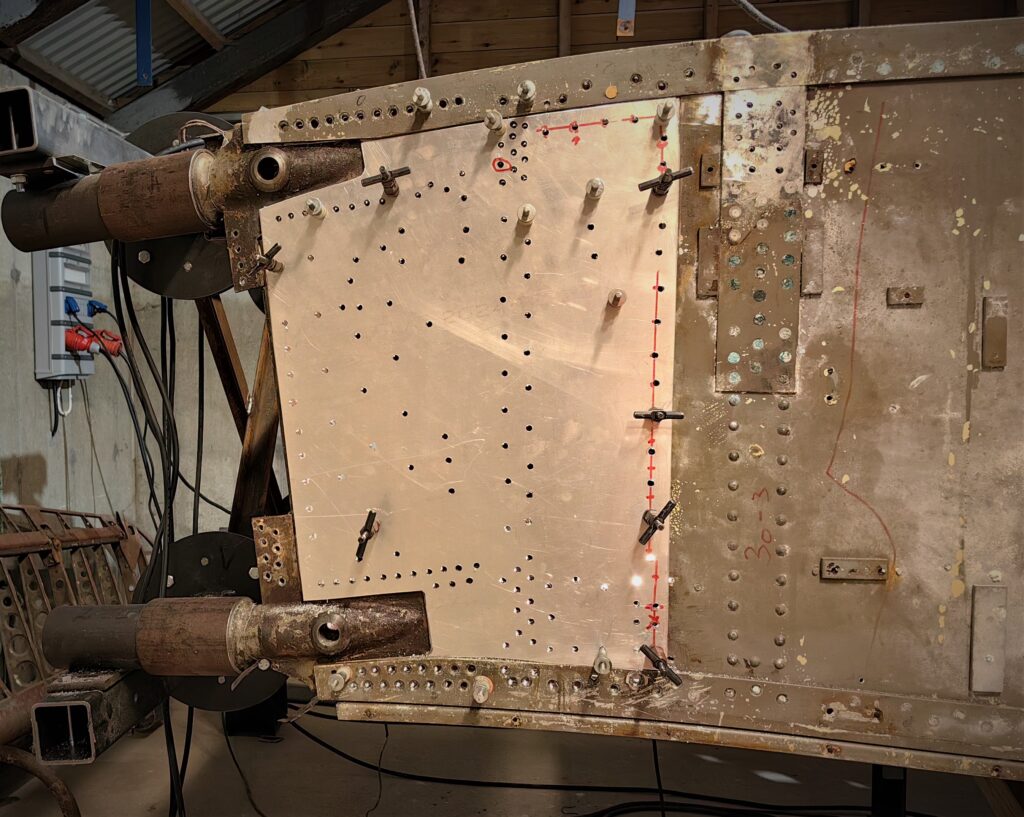

Senterseksjonen er den delen av flyet som er mest skadet etter 70 år på fjordbunnen. Likevel er skadene begrenset, alle årene til tross. Vi nærmer oss nå å bli ferdige med å utbedre korrosjon i fremre styrbord hjørne. Det arbeides parallelt med å fjerne korrosjon fra babord fremre hjørne. Her har vi valgt å ikke å løsne noen av vingefestene. Det var betydelige korrosjonsskader på webbingen like innenfor vingefestene. Den skadde delen av webbingen er blitt fjernet og nye plater er på vei til å bli naglet på plass. Babord fremre flottørfeste er blitt demontert og venter nå på å bli tilbake montert igjen.

Så langt har arbeidet med senterseksjonen vært en læreprosess. Vi måtte først lære oss hvordan seksjonen faktisk var blitt bygget. Det finnes ingen teknisk dokumentasjon som vi kan støtte oss på i arbeidet. Underveis har vi også fått innsikt i hvordan vi kan tolke omfanget av den korrosjonen som er synlig. Her har vi fått flere positive overraskelser. Erfaringene som vi har gjort har også lært oss hvilke av flybransjens måter å gjøre reparasjoner på som fungerer for oss.

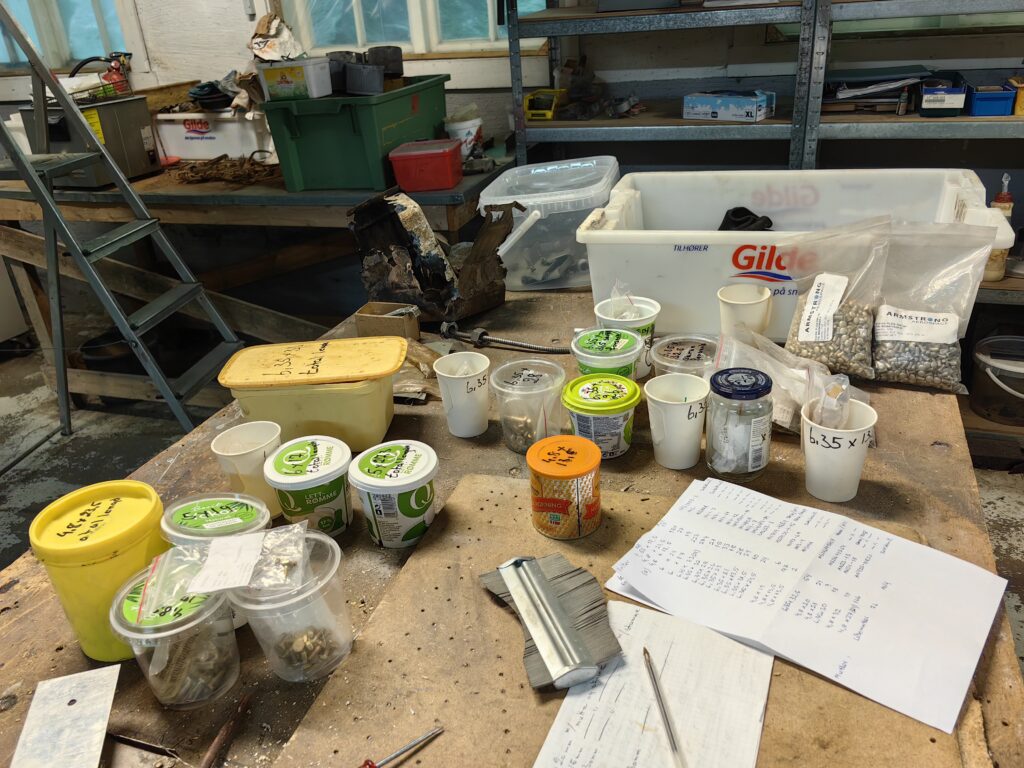

Det har vist seg å være vanskelig å skaffe utstyr og materialer som vi kan bruks i arbeidet. Dette har kostet oss mye tid og arbeid som vi heller ville ha brukt til å jobbe på senterseksjonen. Heldigvis har vi gode venner rundt oss som har kunnet hjelpe oss et stykke på vei.