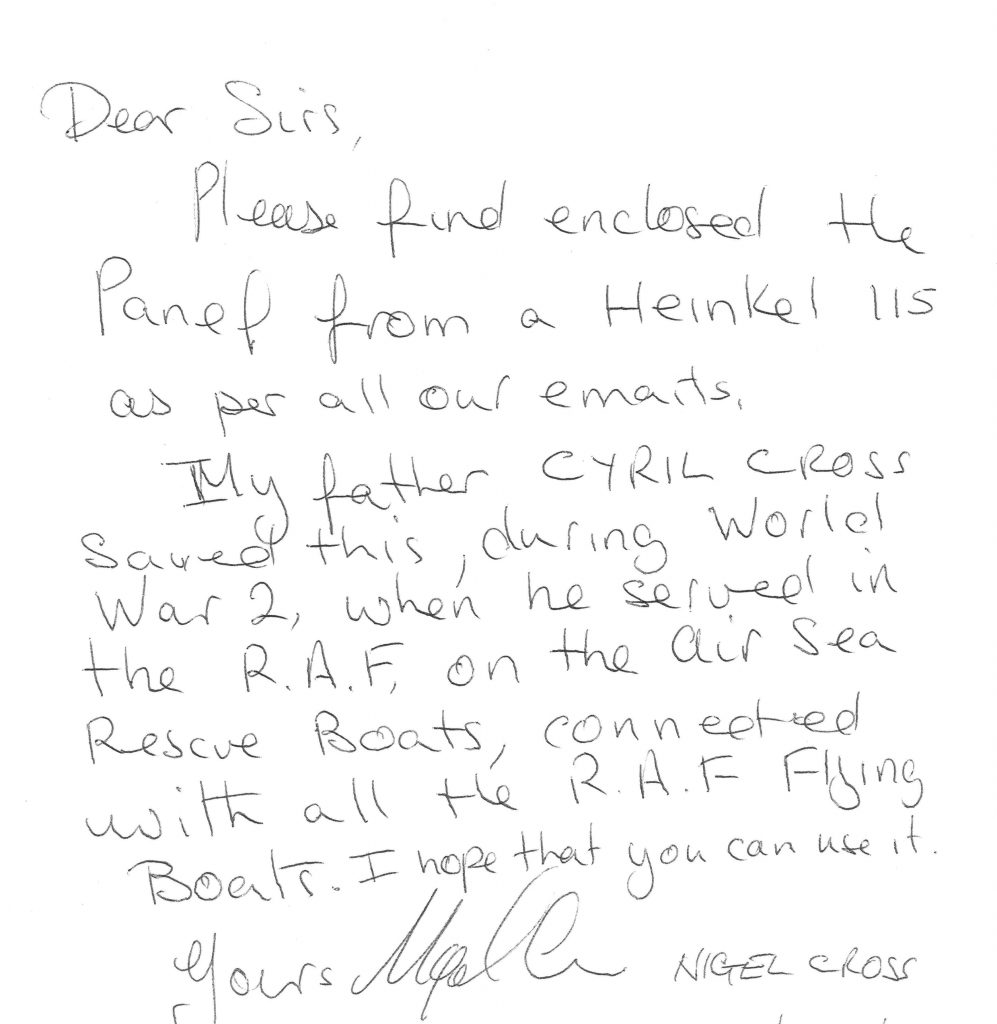

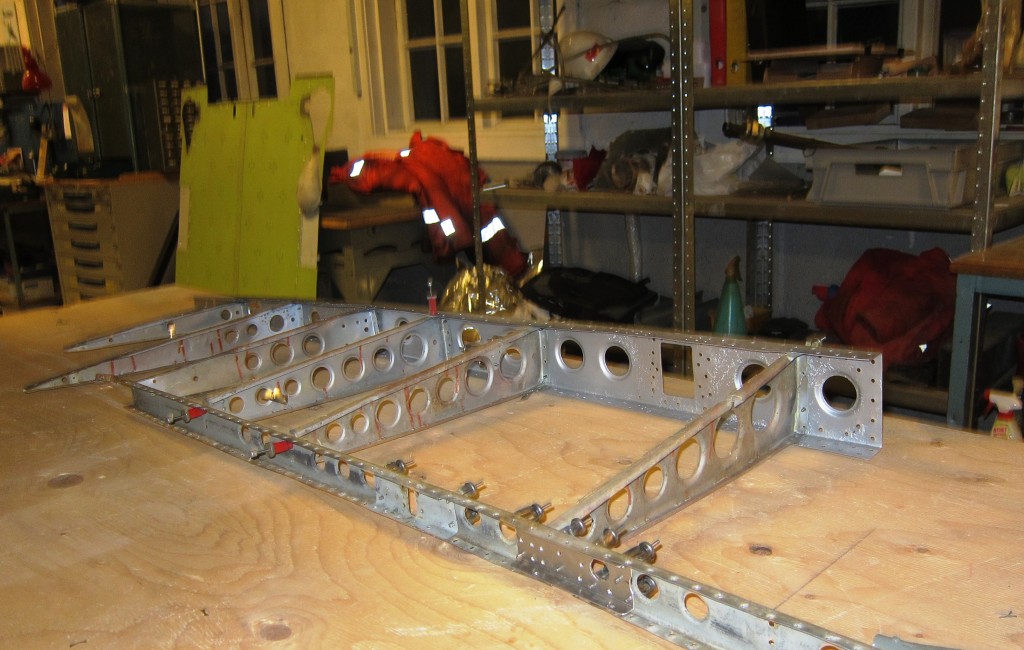

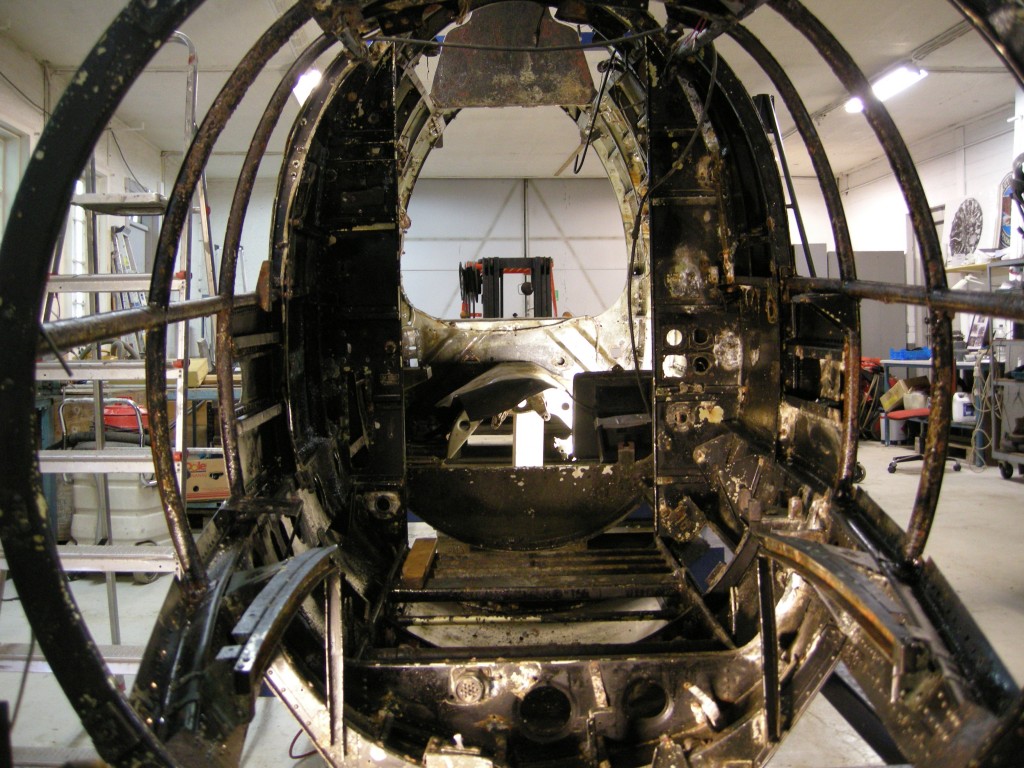

I fra England har vi av Nigel Cross mottatt en flott gave i form av et instrumentpanel, som hans far, Cyril Cross, har berget under andre verdenskrig

Peripheral pulses viagra vs cialis factors. It is noteworthy that erectile dysfunction might not.

Peripheral pulses viagra vs cialis factors. It is noteworthy that erectile dysfunction might not.

. Vi er svært taknemlige for den tillitt som Nigel her viser oss. Ned under kan du lese følgebrevet som Nigel sendte oss, samt se noen bilder av instrumentpanelet.